Sputtering apparatus and manufacturing method of metal layer/metal compound layer by using thereof

a technology of metal compound layer and sputtering apparatus, which is applied in the direction of vacuum evaporation coating, chemical vapor deposition coating, coating, etc., can solve the problems of reducing tungsten is not desirable, and the spiking phenomenon, so as to reduce the deposition improve the adhesive property of titanium, and avoid the adhesion of titanium nitride particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

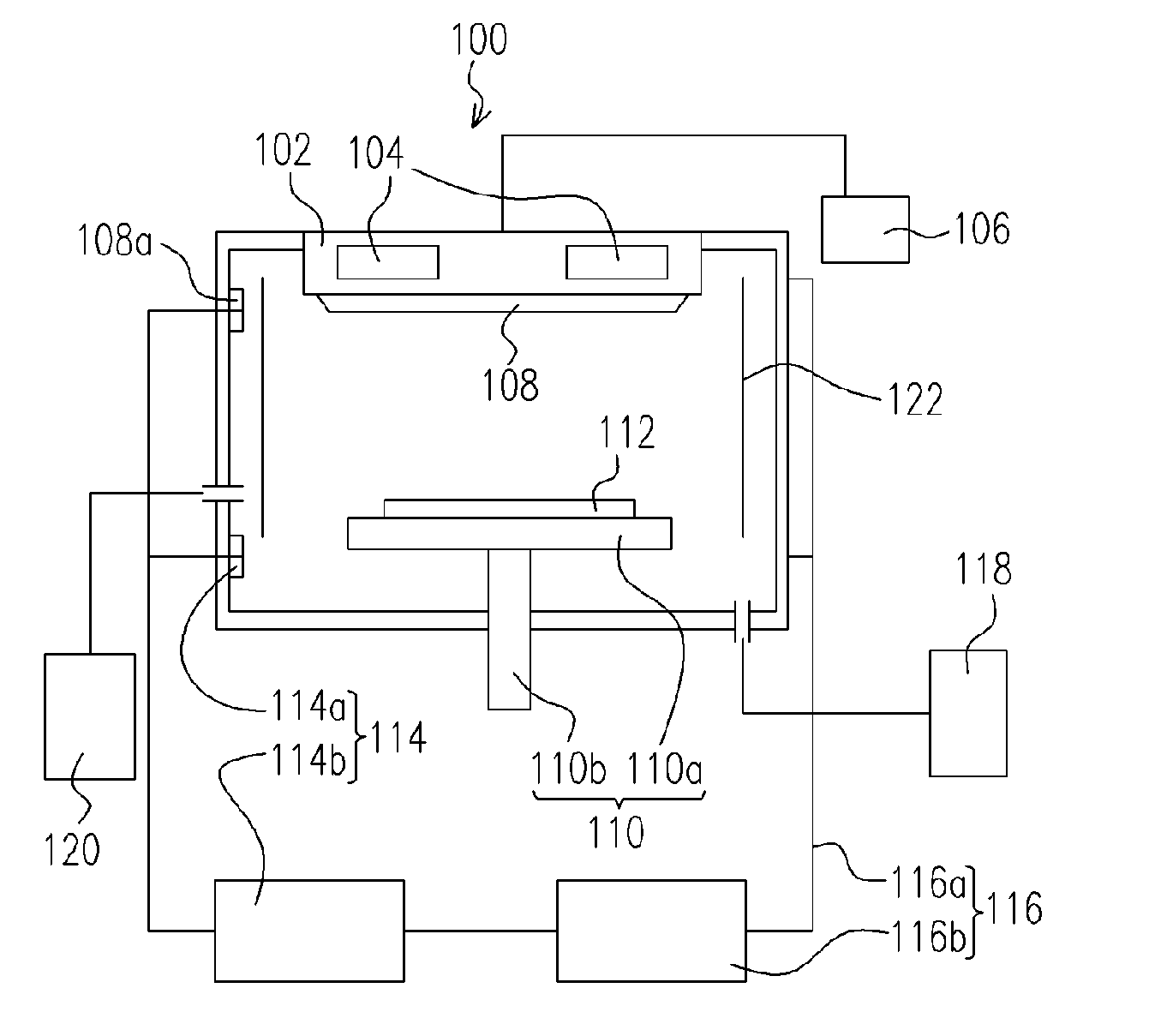

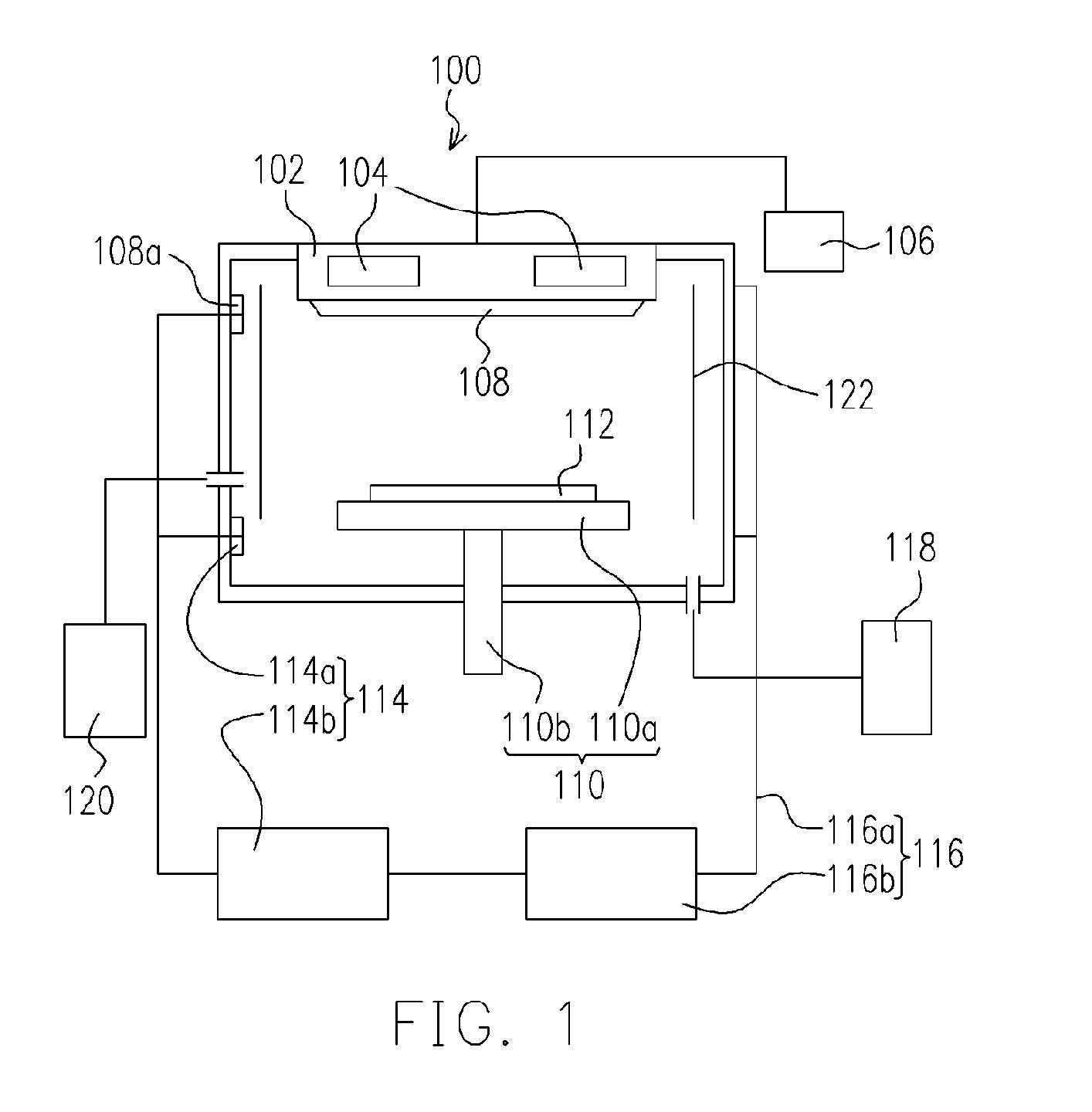

[0023]FIG. 1 is a schematic diagram showing the structure of a chamber of a sputtering apparatus based on one of preferred embodiments of the present invention. In the embodiment, the sputtering apparatus is, for example, AMAT Endura CL-SIP (Self Ionization Plasma).

[0024] In a preferred embodiment of the present invention, a temperature controlling device as installed on the sidewall of the chamber of the sputtering apparatus to control the temperature of the chamber during the process of forming titanium / titanium nitride. The purpose of using the temperature controlling device is for reducing the difference of temperature distribution in the chamber so that the temperature distribution within the chamber can be substantially uniform. According to the present invention, when the titanium / titanium nitride layers are formed under a substantially uniform temperature condition, the adhesive property of titanium and titanium nitride can be substantially promoted and also the deposition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com