Production device of RI-01 crude oil demulsifier

A crude oil demulsifier, RI-01 technology, applied in chemical dehydration/demulsification, pressure vessels used in chemical processes, chemical/physical/physical-chemical stationary reactors, etc., can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

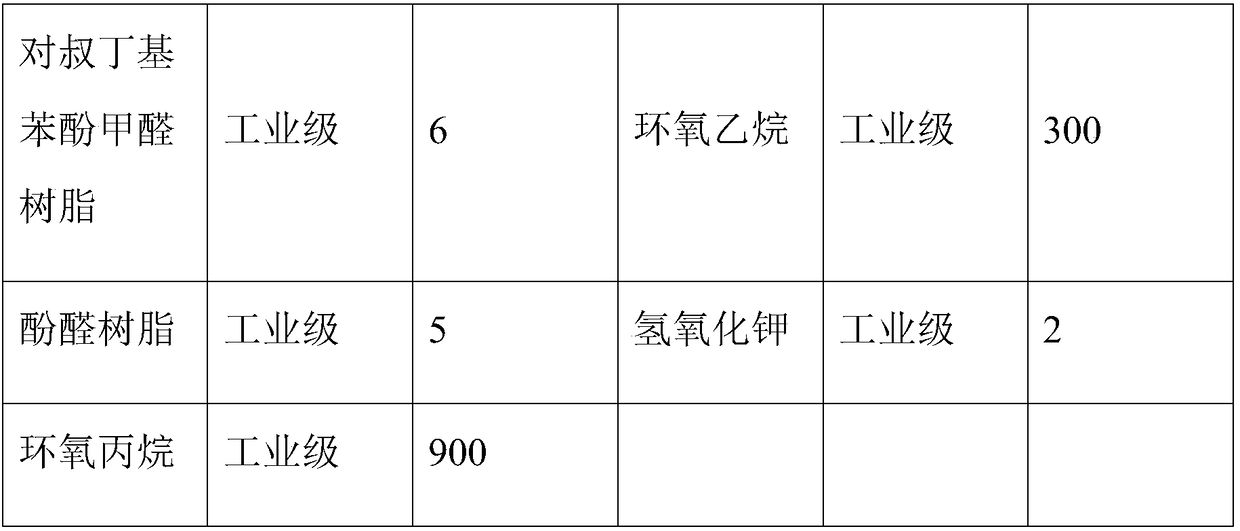

[0008] Production raw materials and dosage

[0009]

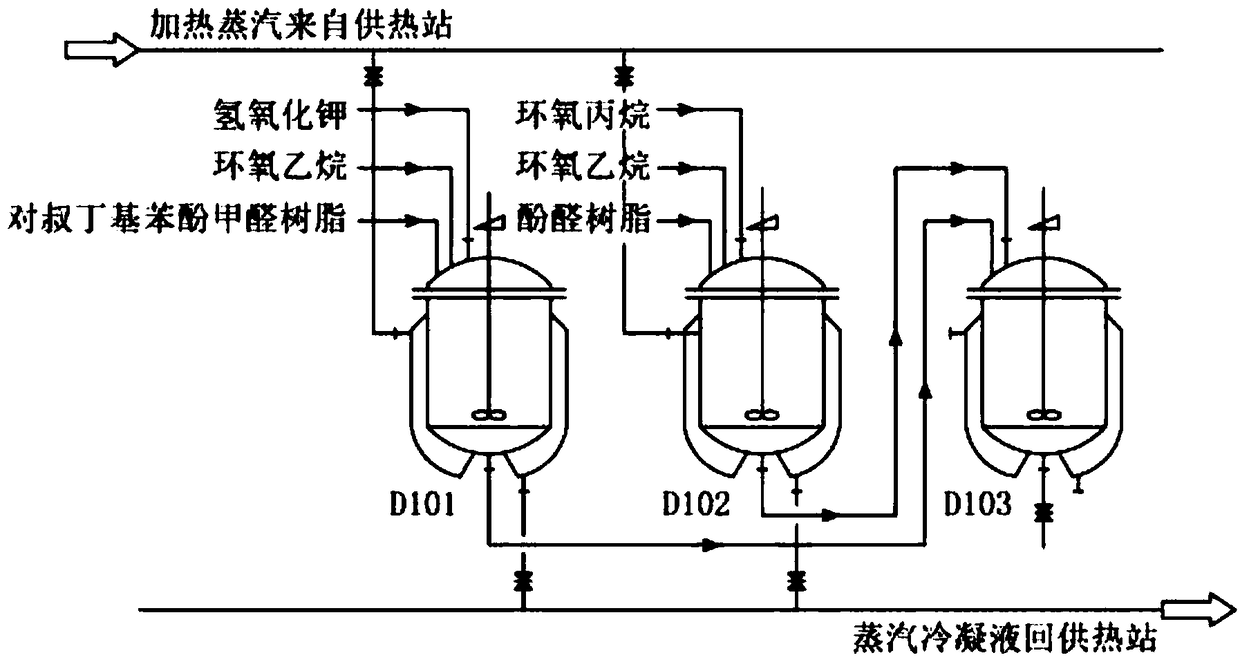

[0010] The production device of RI-01 crude oil demulsifier mainly includes: autoclave (D101), reaction kettle (D102), mixing kettle (D103), wherein, the autoclave (D101) is connected with the mixing kettle (D103), and the reaction kettle ( D102) is connected with mixing kettle (D103), wherein, autoclave (D101) nominal volume is 700L, reaction kettle (D102) jacket capacity is 160L, and mixing kettle (D103) outer pot diameter is 900mm.

[0011] RI-01 crude oil demulsifier production device, the production process is: add p-tert-butylphenol formaldehyde resin, ethylene oxide and potassium hydroxide catalyst with a mass fraction of 0.6% into the autoclave D101 with cooling jacket and agitator Inside, sealed, after nitrogen replacement, start stirring, raise the temperature, control the reaction temperature at 115°C, until the autoclave pressure stops rising and gradually drops to normal pressure, the reaction is complete, a...

example 2

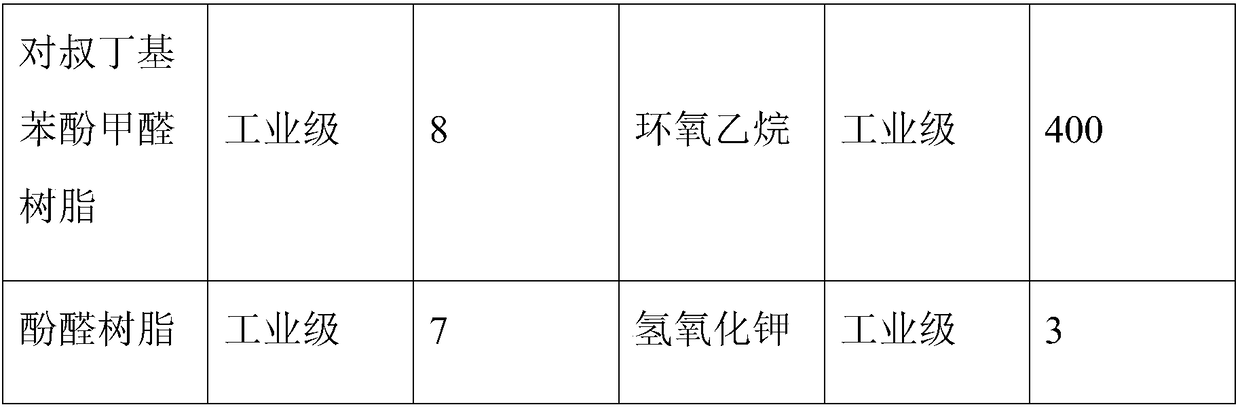

[0015] Production raw materials and dosage

[0016]

[0017]

[0018] The production device of RI-01 crude oil demulsifier mainly includes: autoclave (D101), reaction kettle (D102), mixing kettle (D103), wherein, the autoclave (D101) is connected with the mixing kettle (D103), and the reaction kettle ( D102) is connected with mixing kettle (D103), wherein, autoclave (D101) nominal volume is 760L, reaction kettle (D102) jacket capacity is 190L, and mixing kettle (D103) outer pot diameter is 970mm.

[0019] RI-01 crude oil demulsifier production device, the production process is: add p-tert-butylphenol formaldehyde resin, ethylene oxide and potassium hydroxide catalyst with a mass fraction of 0.8% into the autoclave D101 with cooling jacket and agitator Inside, sealed, after nitrogen replacement, start stirring, raise the temperature, control the reaction temperature at 120°C, until the autoclave pressure stops rising and gradually drops to normal pressure, the reaction is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com