Patents

Literature

368results about How to "Reduction of intermediate links in the reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

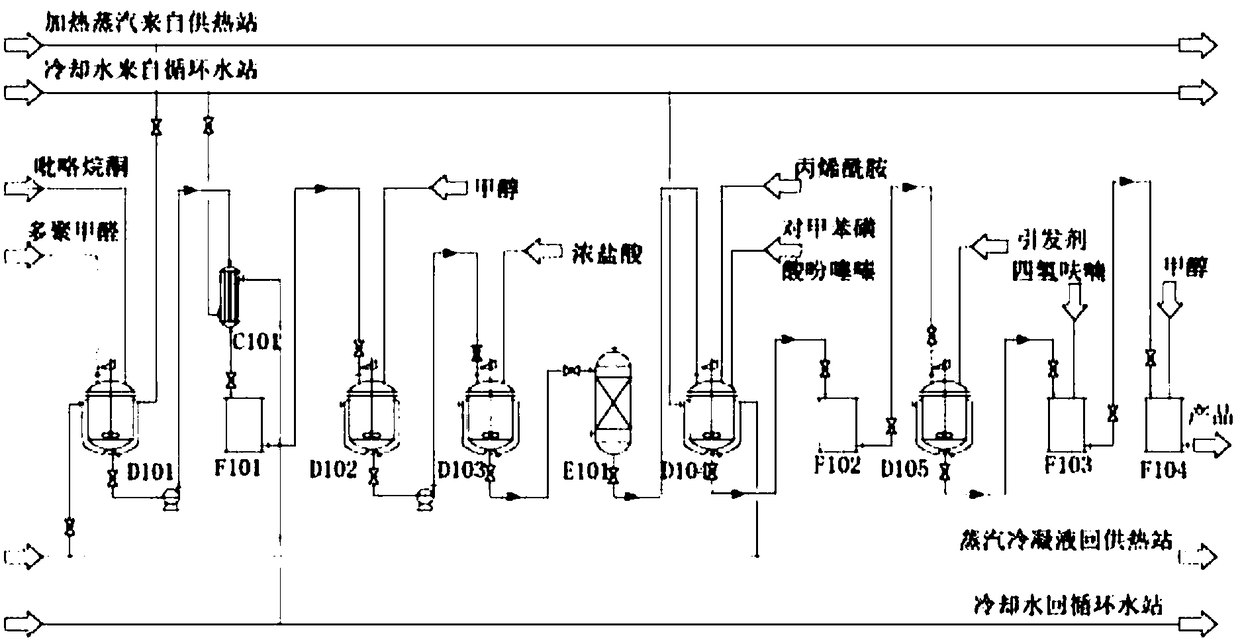

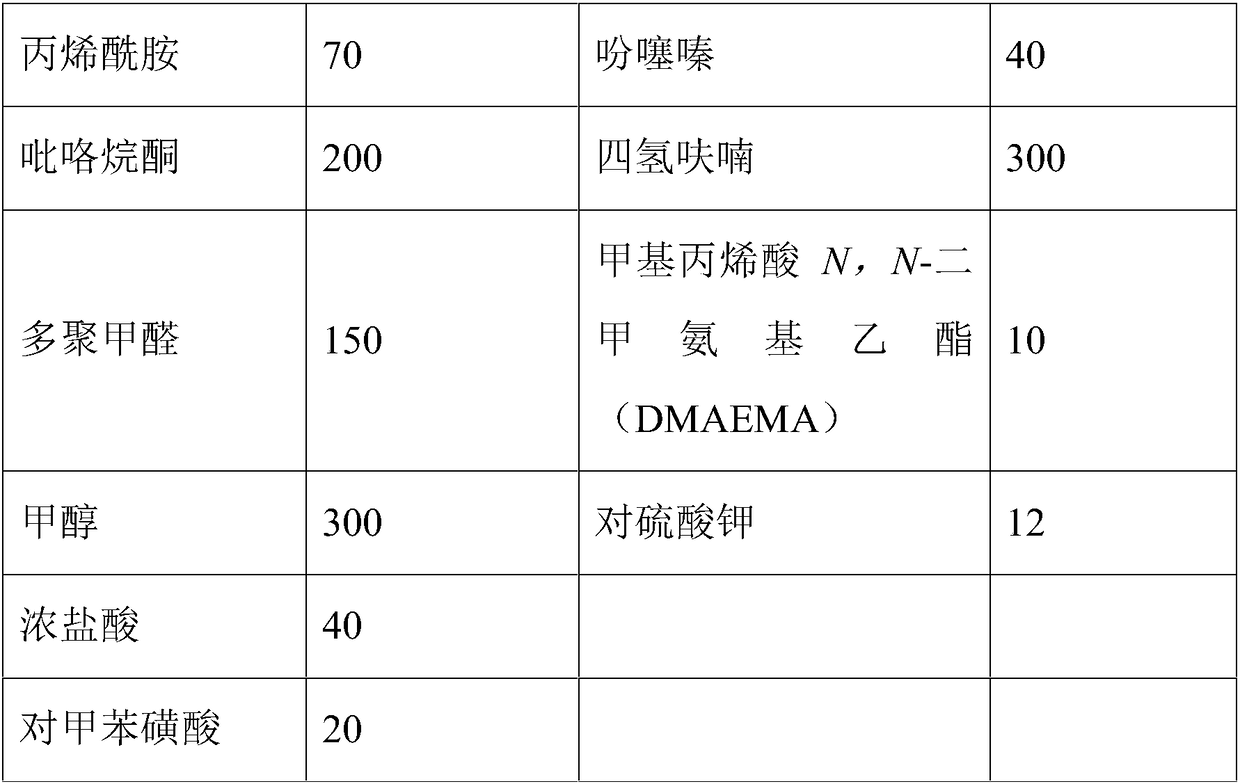

Production device of medical hydrogel polyacrylamide

InactiveCN108239236AReduction of intermediate links in the reactionLow reaction temperaturePolymer scienceDistillation

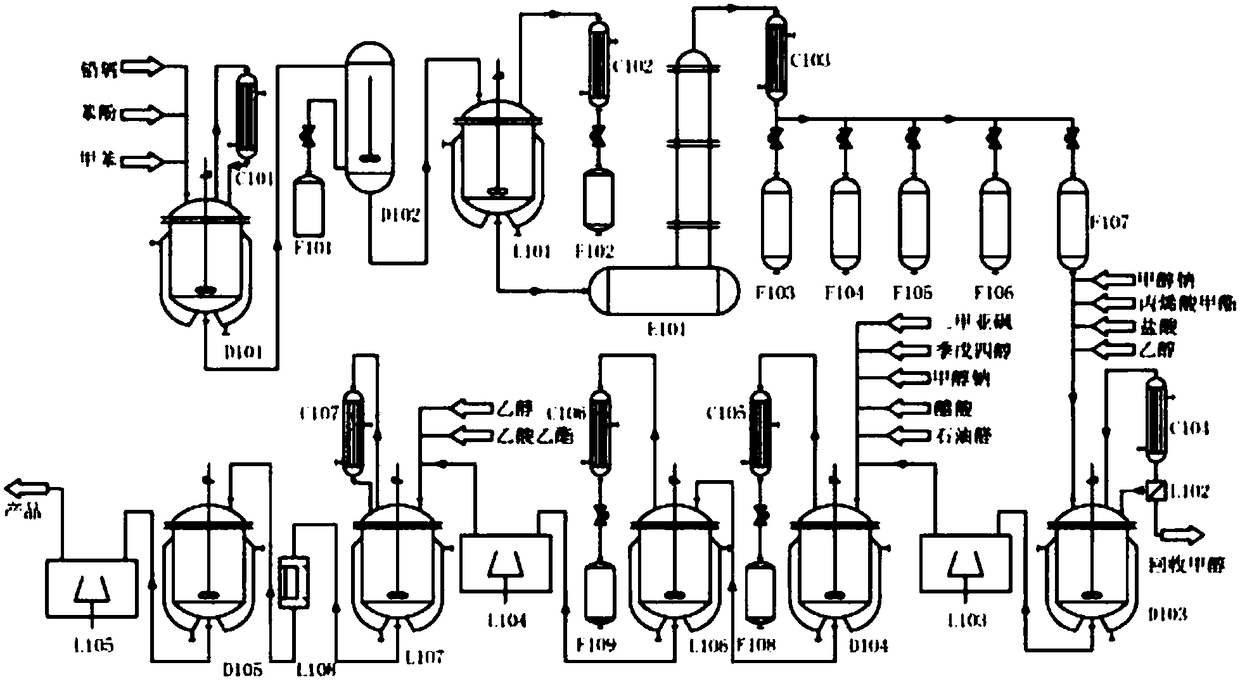

The invention discloses a production device of medical hydrogel polyacrylamide. The production device mainly comprises a polymerization kettle (D101), a cooler (C101), a crystallization tank (F101), apolymerization kettle (D102), a neutralization kettle (D103), a reduced-pressure distillation tower (E101), a polymerization kettle (D104), a crystallization tank (F102), a polymerization kettle (D105), a sedimentation tank (F103) and a dissolving tank (F104), wherein the reduced-pressure distillation tower (E101) is connected with the neutralization kettle (D103) and the polymerization kettle (D104) respectively, the polymerization kettle (D105) is connected with the crystallization tank (F102) and the sedimentation tank (F103) respectively, and the nominal volume of the polymerization kettle (D101) is 1200-1300L.

Owner:CHENGDU BO LUO KE TECH CO LTD

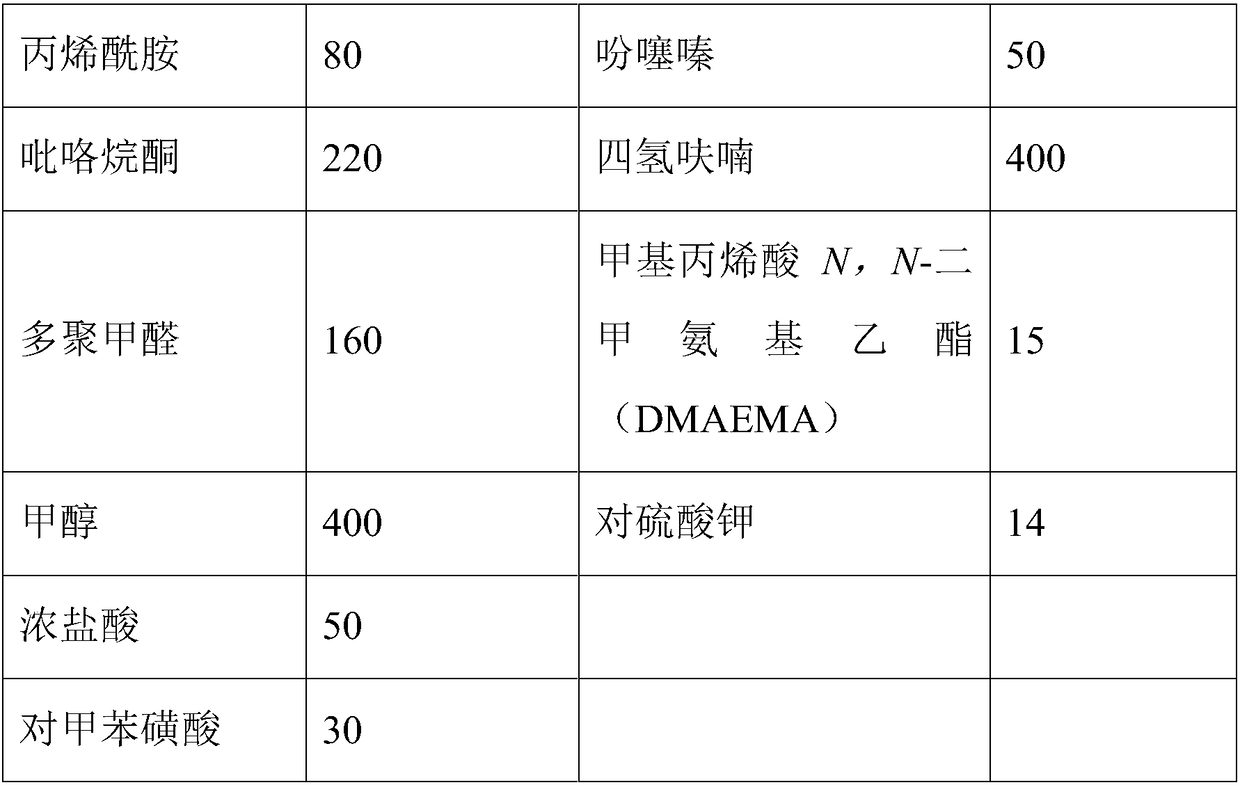

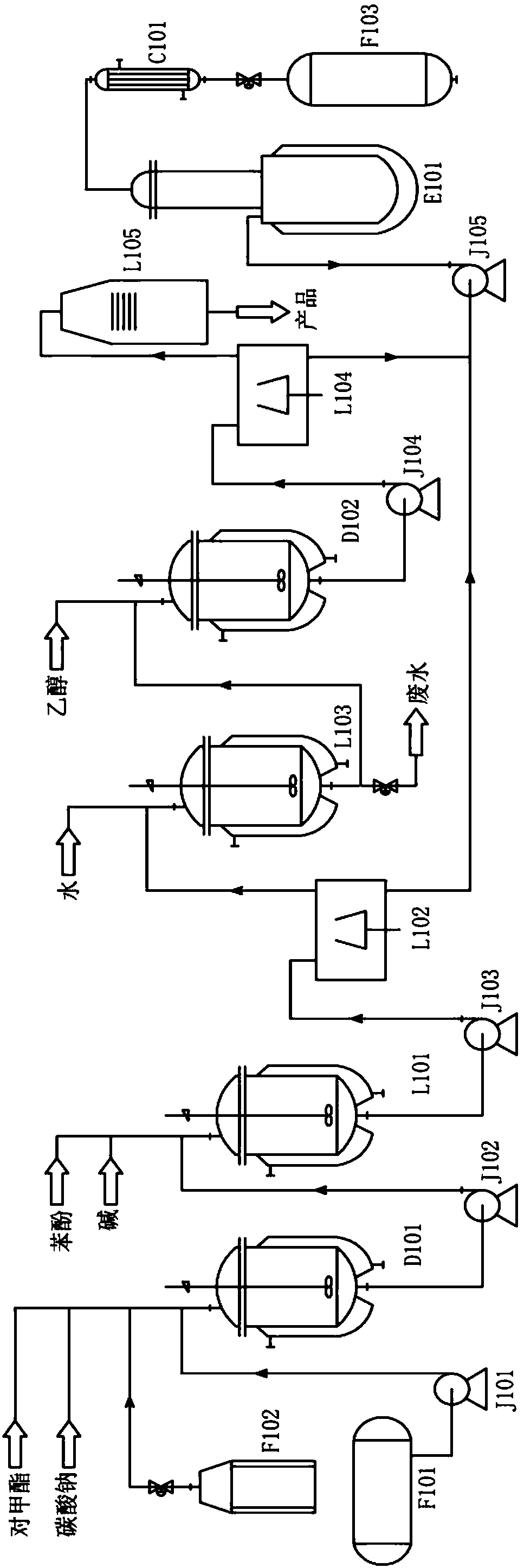

Production device of 1,2-benzisothiazolin-3-one

InactiveCN108239038AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryBenzeneDistillation

A production device of 1,2-benzisothiazolin-3-one mainly comprises a storage tank (F101), a storage tank (F102), a reaction kettle (D101), a bromination kettle (D102), a distillation column (E101), acondenser (C101), a storage tank (F103), a recrystallization kettle (D103), a storage tank (F104), a centrifuge (L101) and a dryer (L102), wherein the storage tank (F101) is used for storing benzene,the storage tank (F102) is used for storing thionyl chloride, the storage tank (F103) is used for recovering benzene and the storage tank (F104) is used for storing water, the bromination kettle (D102) is respectively connected with the reaction kettle (D101) and the distillation tower (E101); the centrifuge (L101) is respectively connected with the recrystallization kettle (D103) and the dryer (L102), and the thickness of the sealing head of the storage tank (F102) is 8-9 mm.

Owner:CHENGDU KE BO TE TECH CO LTD

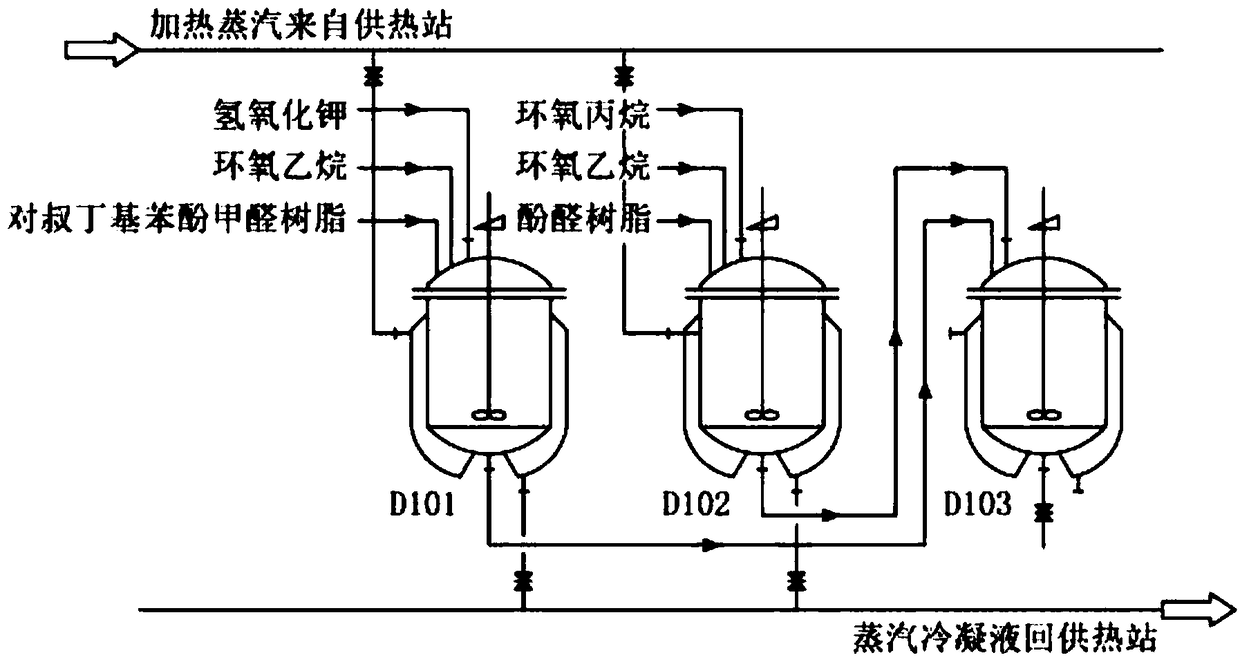

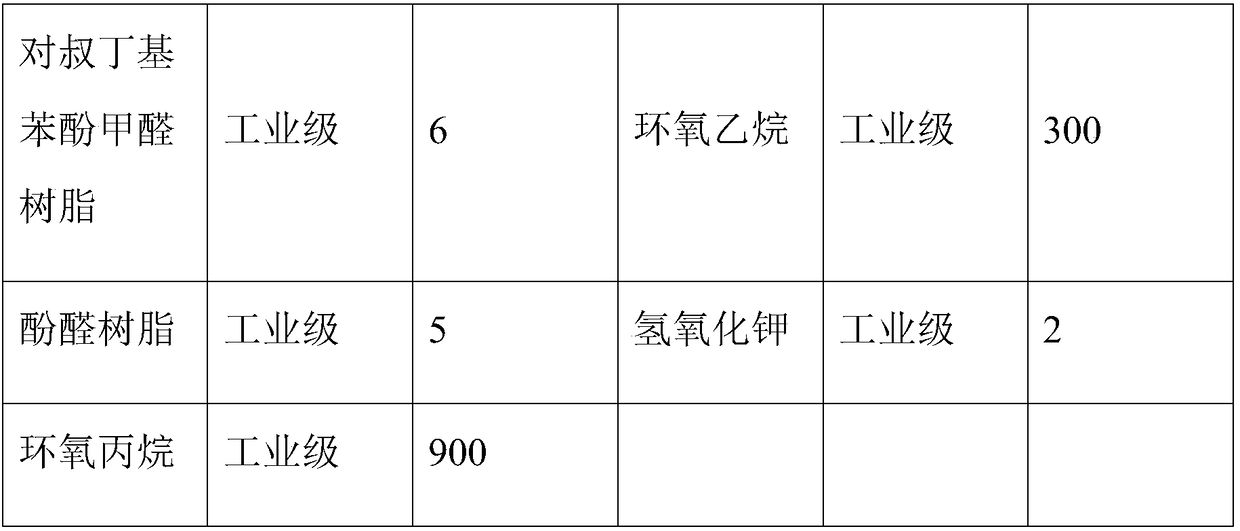

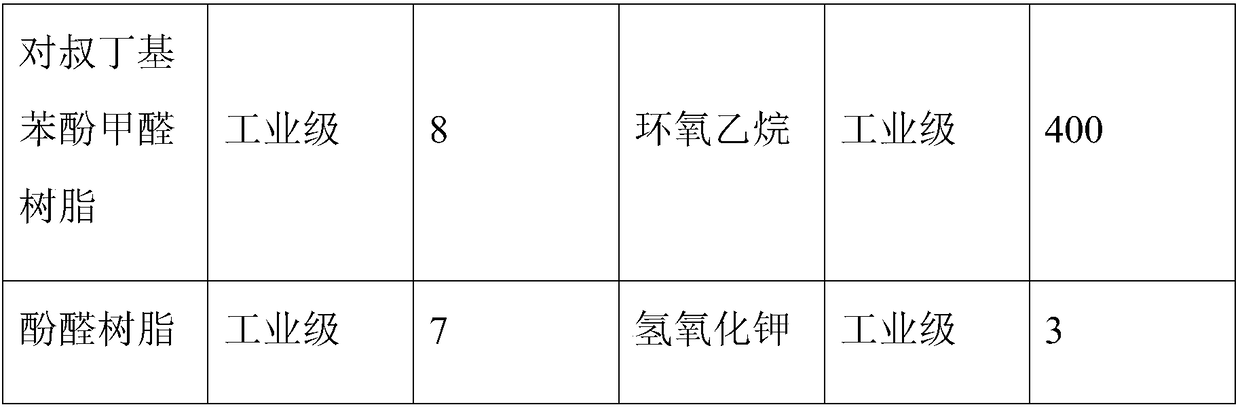

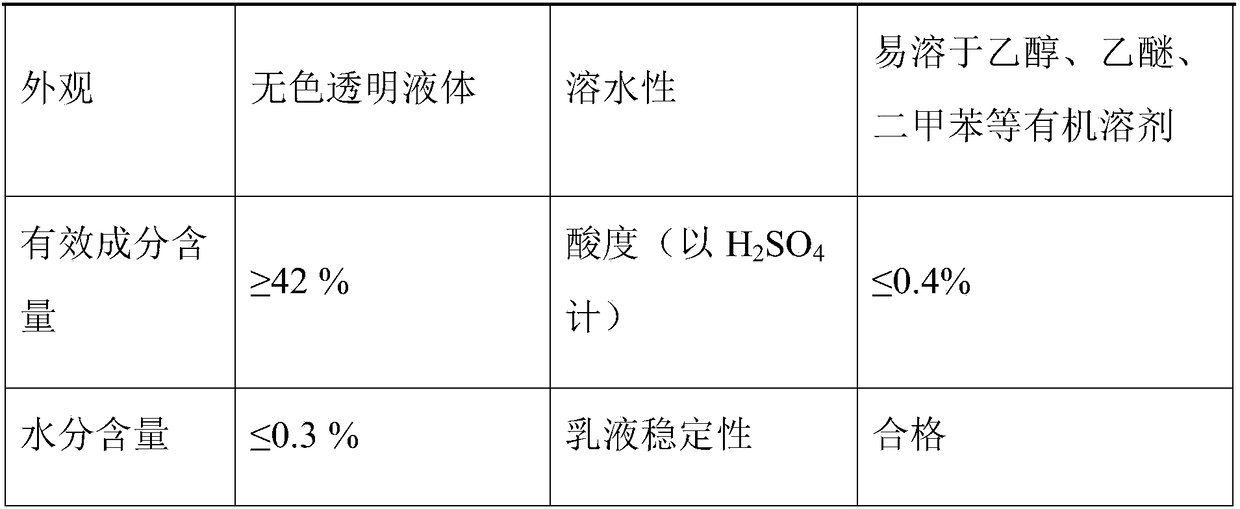

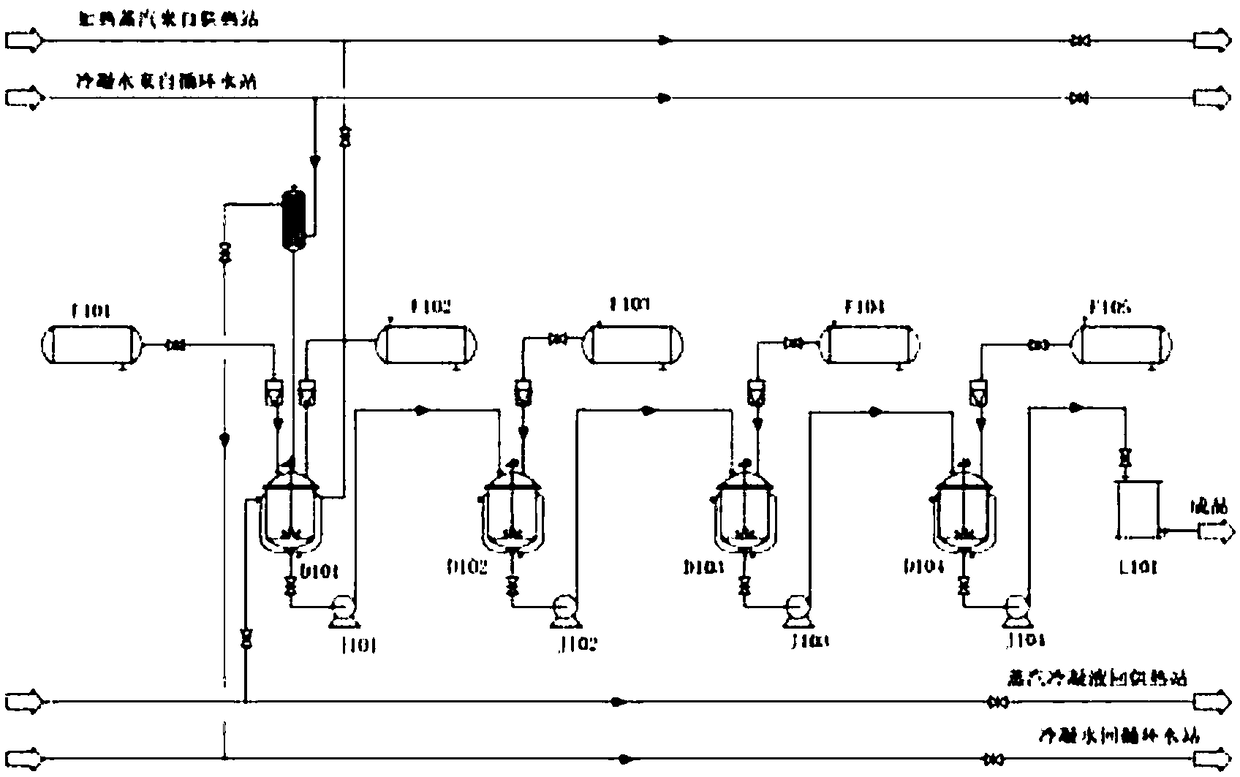

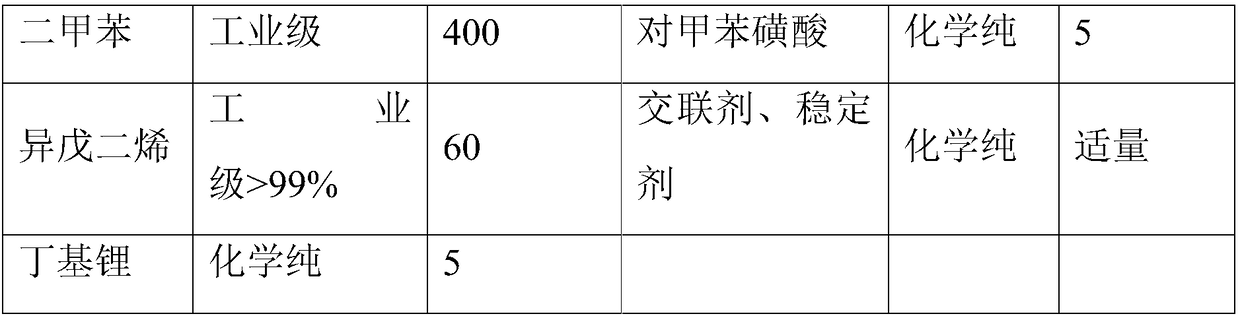

Production device of RI-01 crude oil demulsifier

InactiveCN108236885AUniform reaction temperatureWell mixedDewatering/demulsification with chemical meansChemical/physical/physico-chemical stationary reactorsDemulsifierProcess engineering

The invention discloses a production device of a RI-01 crude oil demulsifier. The production device mainly comprises an autoclave (D101), a reaction kettle (D102), and a mixing kettle (D103), whereinthe autoclave (D101) is connected with the mixing kettle (D103), the reaction kettle (D102) is connected with the mixing kettle (D103), and the autoclave (D101) has a nominal volume of 700-760 L.

Owner:CHENGDU HUI SI DUN TECH CO LTD

Production device of diisopropyl-S-benzyl sulfide phosphate

InactiveCN108239115AReduction of intermediate links in the reactionLow reaction temperatureGroup 5/15 element organic compoundsPhosphateProcess engineering

The invention discloses a production device of diisopropyl-S-benzyl sulfide phosphate. The production device mainly comprises a reaction kettle (D101), a condenser (C101), a deacidification kettle (D102), a condenser (C102), an exhaust gas absorption tower (E101), a condenser (C103), a reaction kettle (D103), a condenser (C104), a standing kettle (D104), a filter (M101), a diaphragm evaporator (L101), a condenser (C105) and a receiver (F101), wherein the condenser (C103) is respectively connected with the deacidification kettle (D102) and the reaction kettle (D103), the filter (M101) is respectively connected with the standing kettle (D104) and the diaphragm evaporator (L101), and the reaction kettle (D101) has a jacket capacity of 330-360L.

Owner:CHENGDU WEI ER BO DUN TECH CO LTD

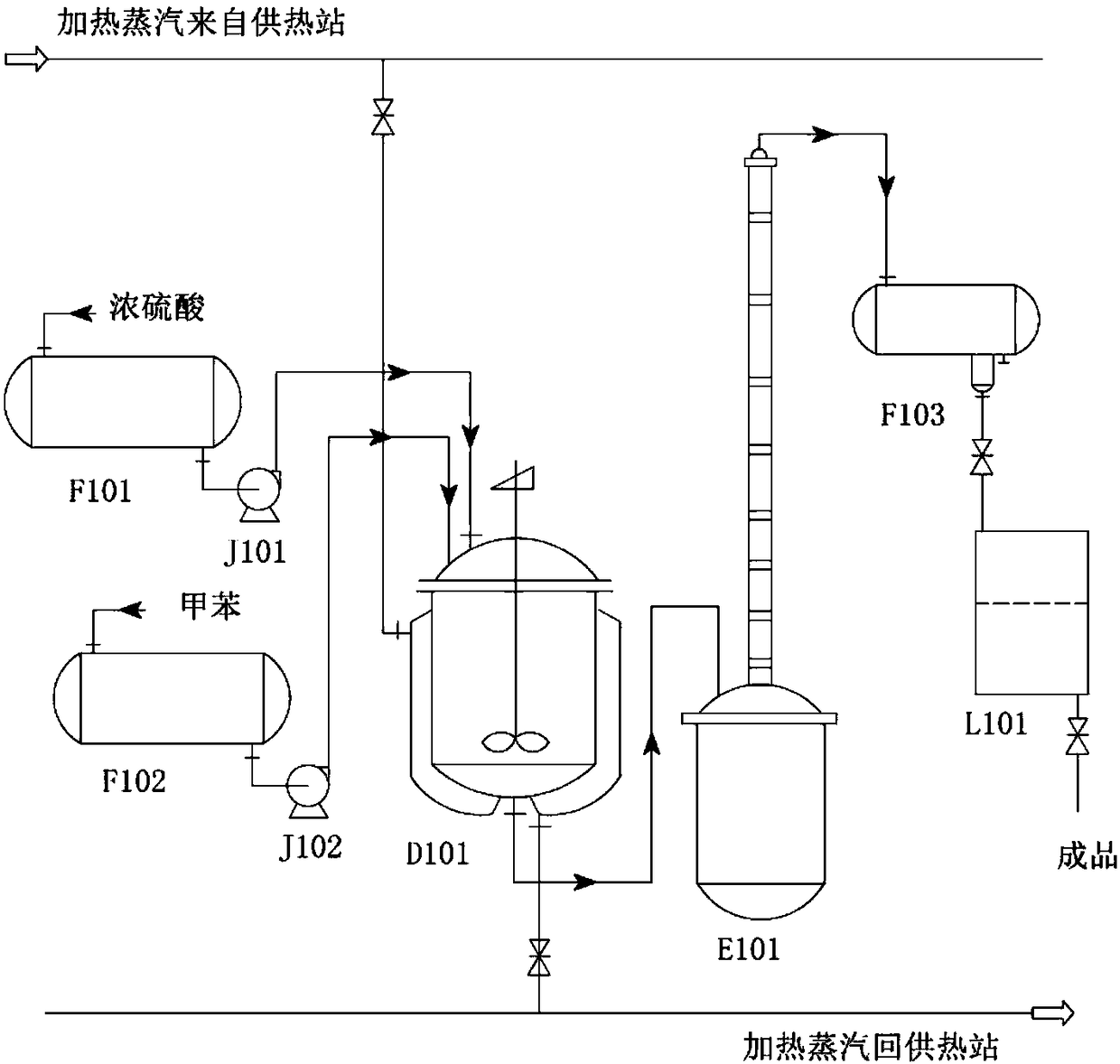

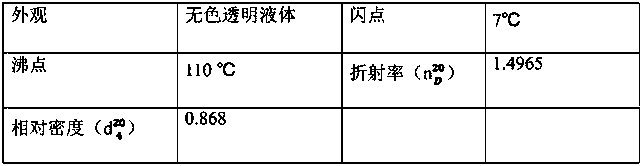

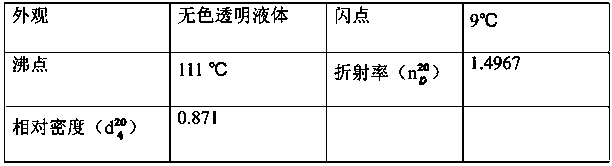

Production device of medicine intermediate high-purity toluene

InactiveCN108238839AReduction of intermediate links in the reactionLow reaction temperatureHydrocarbon purification/separationHydrocarbonsFractionating columnToluene

A production device of medicine intermediate high-purity toluene mainly comprises a storage tank (F102), a storage tank (F103), a stirring kettle (D101), a distillation column (E101), a storage tank (F101), a pump (J101), a pump (J102) and an ultra-clean filter (L101), wherein the storage tank (F102) is used for storing toluene, the storage tank (F103) is used for storing crude products; the storage tank (F101) is used for storing sulfuric acid; the pump (J102) is respectively connected with the storage tank (F102) and the stirring kettle (D101) , the storage tank (F103) is respectively connected with the distillation column (E101) and the ultra-clean filter (L101), wherein the diameter of the storage tank (F103) barrel is 700-800 mm.

Owner:成都盛金缘餐饮文化传播有限公司

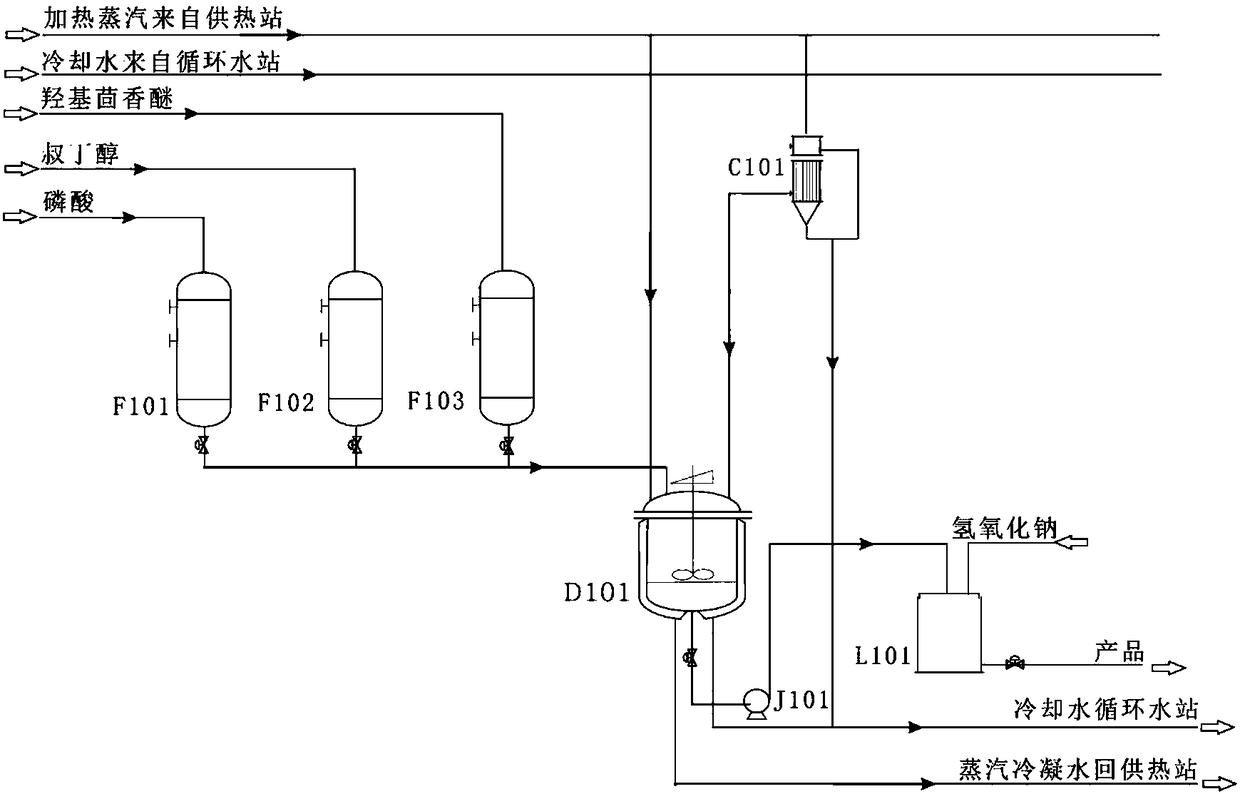

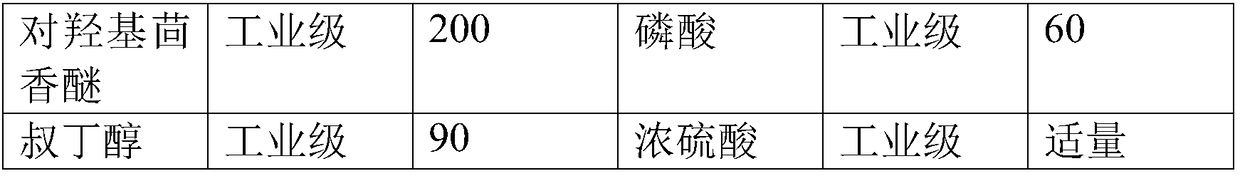

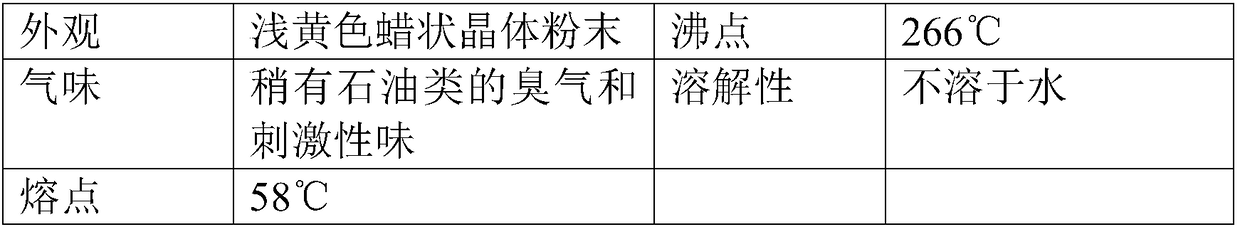

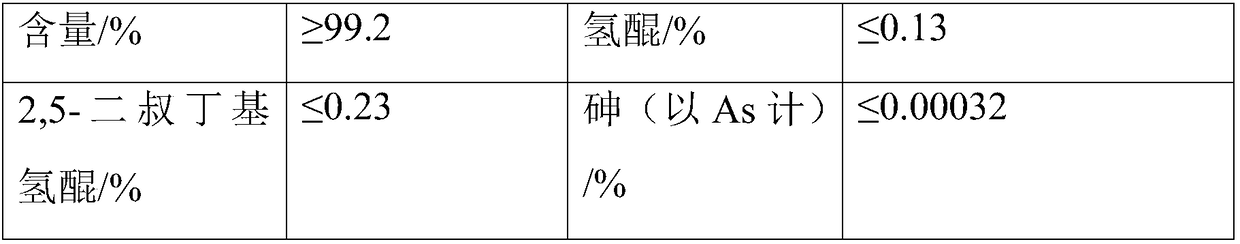

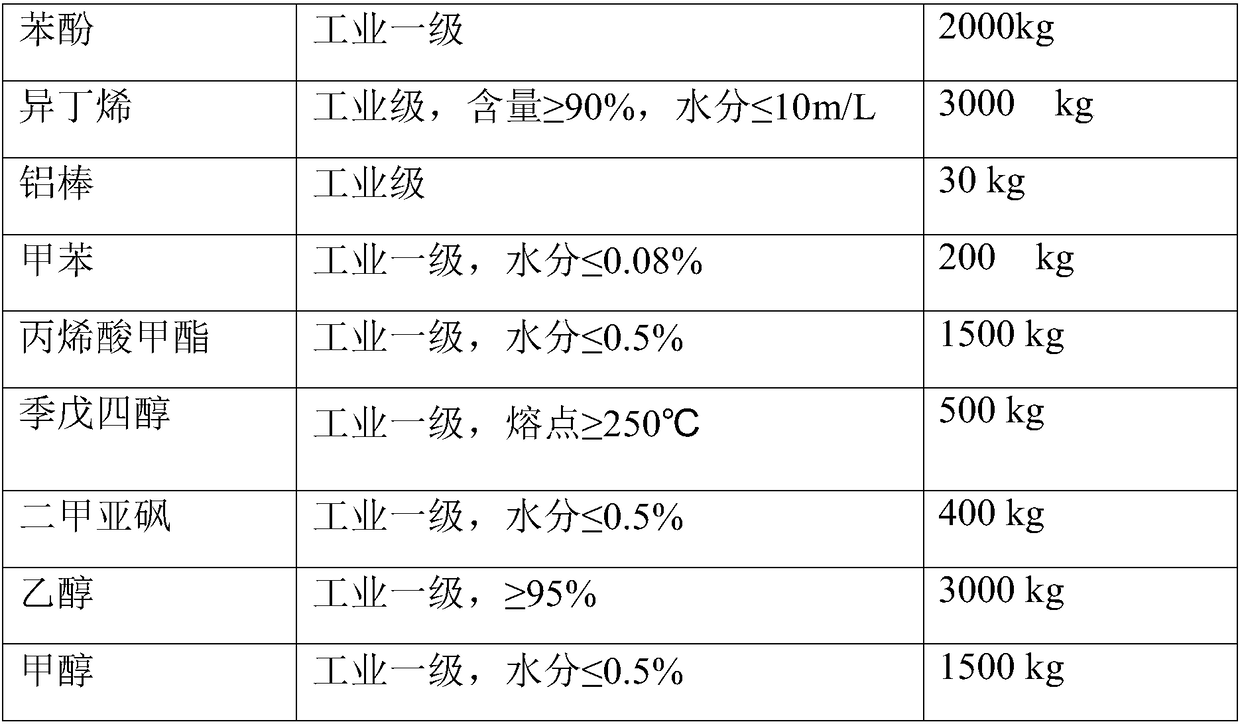

Production apparatus for anti-oxidant butylated hydroxyanisole

InactiveCN108238857AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryOrganic compound preparationButylated hydroxyanisoleProcess engineering

The invention provides a production apparatus for the anti-oxidant butylated hydroxyanisole. The production apparatus mainly comprises a storage tank 1 (F101), a storage tank 2 (F102), a storage tank3 (F103), a reaction kettle (D101), a condenser (C101), a transfer pump (J101) and a rinsing bath (L101), wherein the storage tank 1 (F101) is connected with the reaction kettle (D101); the storage tank 2 (F102) is connected with the reaction kettle (D101); the storage tank 3 (F103) is connected with the reaction kettle (D101); the condenser (C101) is connected with the reaction kettle (D101); thetransfer pump (J101) is connected with the reaction kettle (D101); and the rinsing bath (L101) is connected with the transfer pump (J101).

Owner:CHENGDU WEI ER BO DUN TECH CO LTD

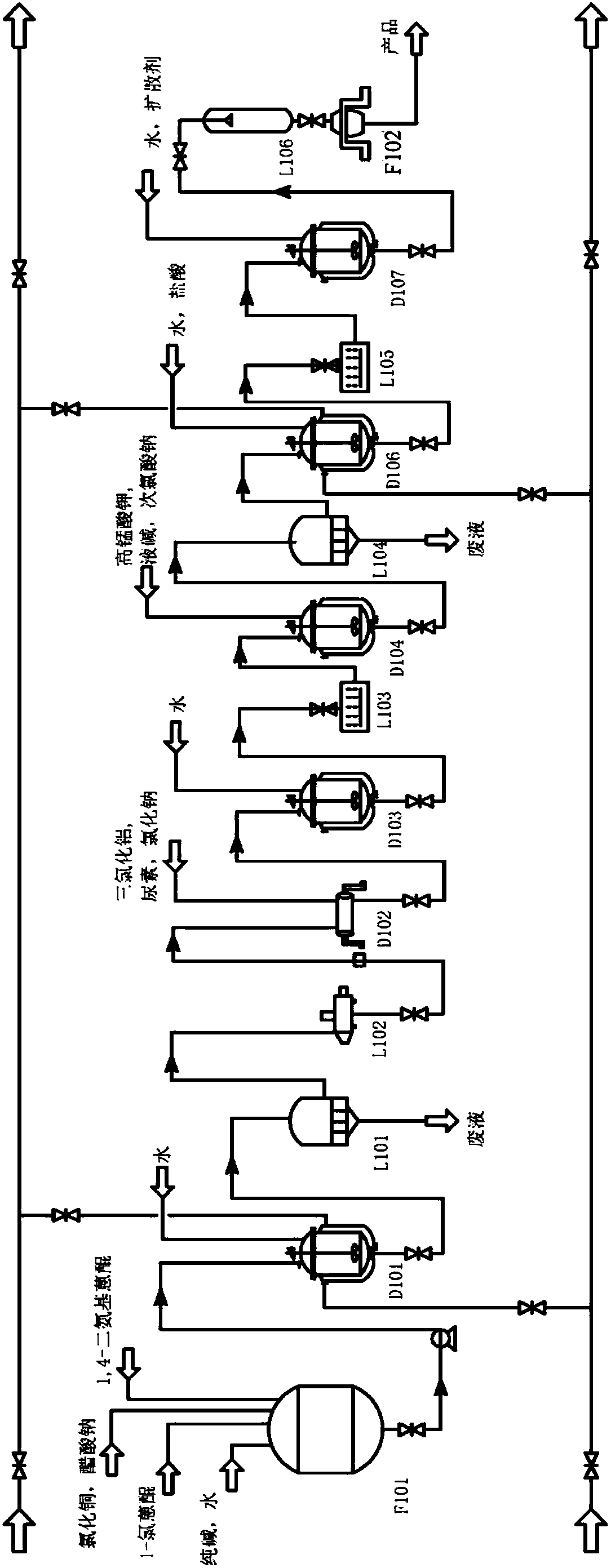

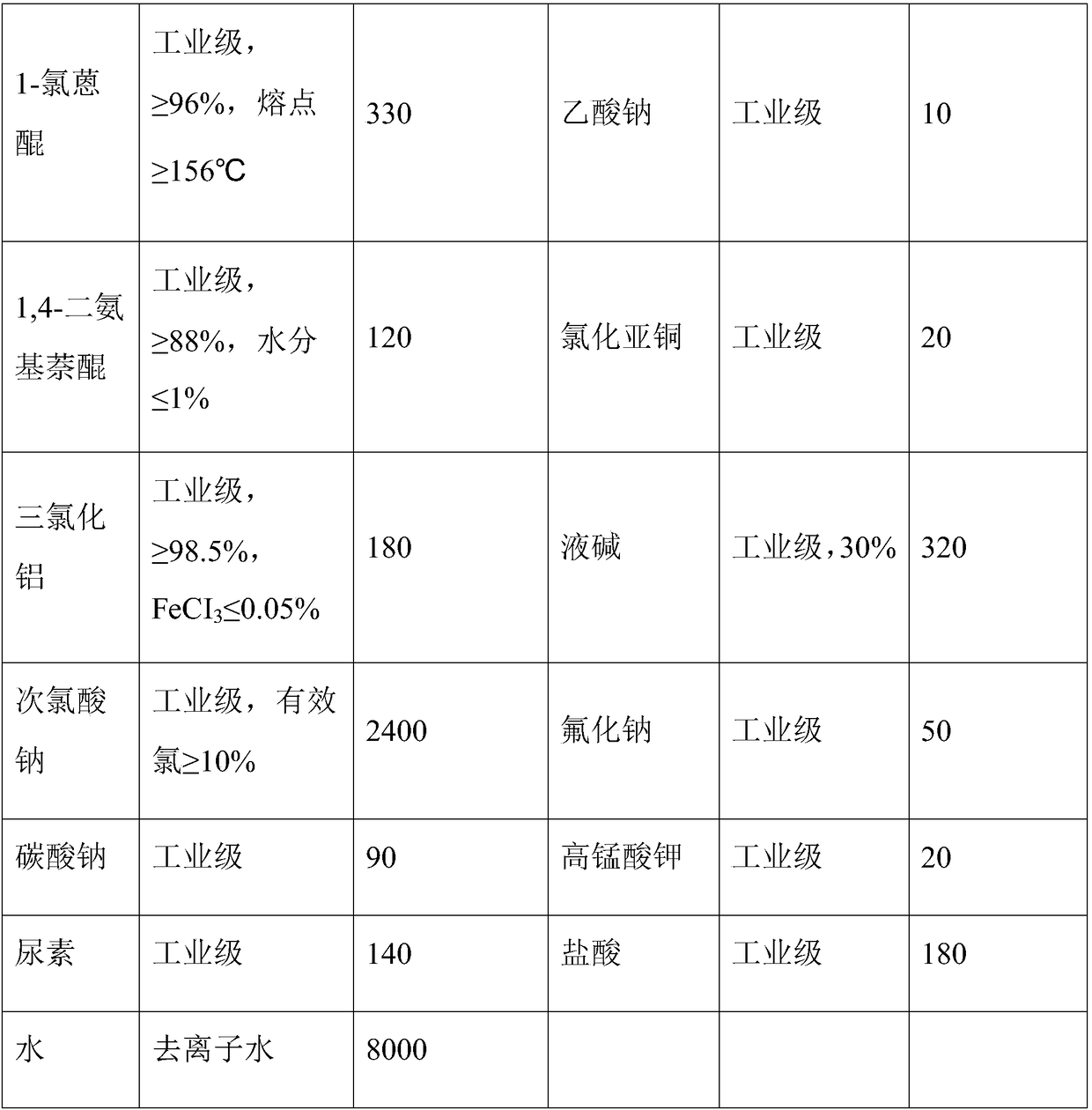

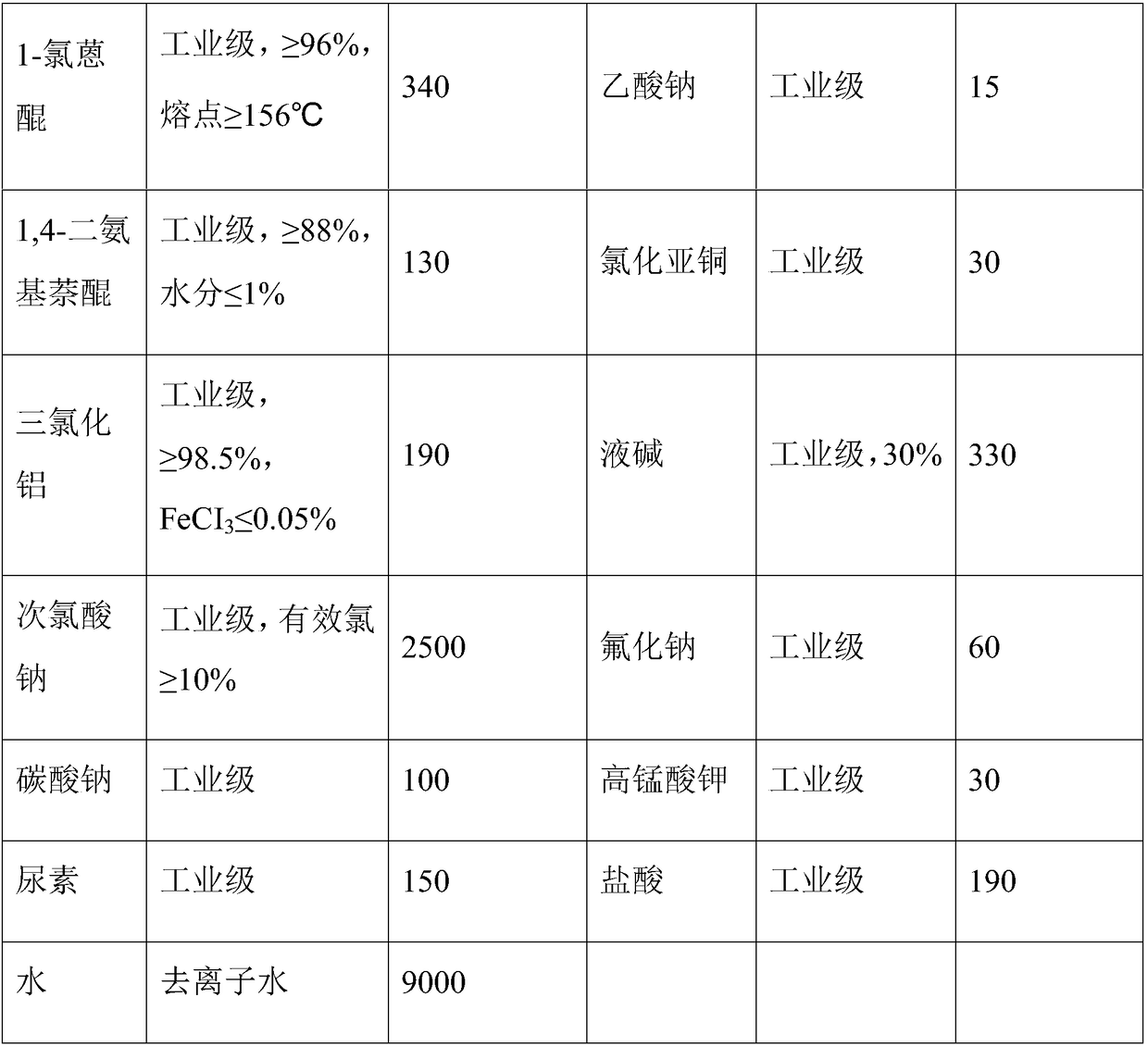

Method for producing oil antioxidant namely tert-butyl hydroquinone

InactiveCN108299164AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryOrganic compound preparationChemistryHydroquinone Compound

Owner:CHENGDU PU LAI & TECH CO LTD

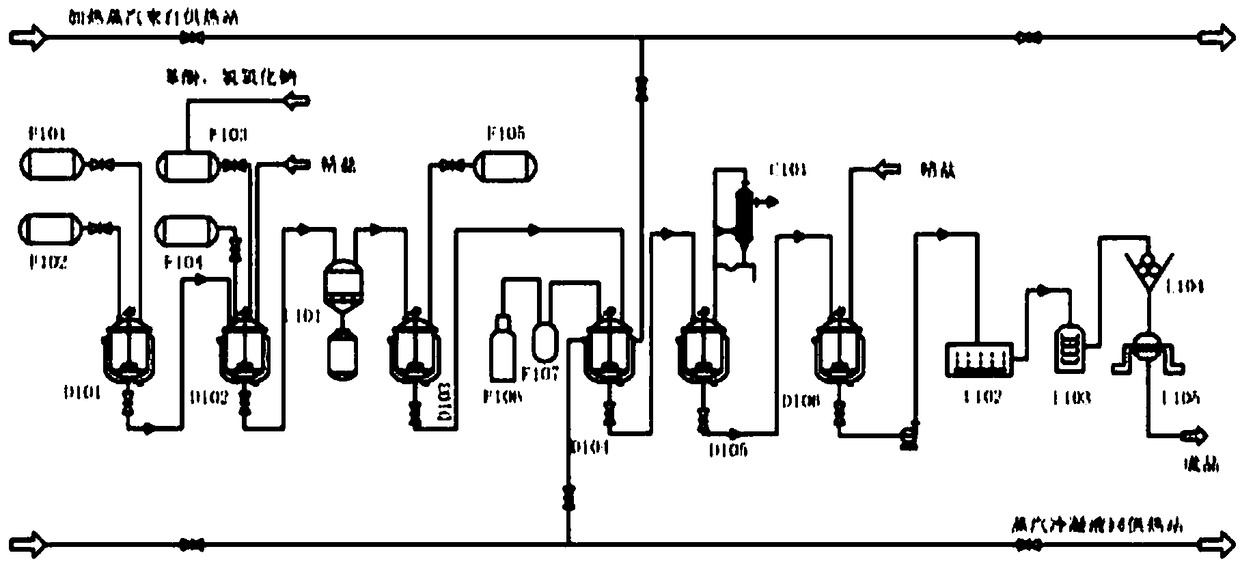

Production device of viscose fiber dyeing agent vat brown BR

InactiveCN108239092AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryFiberPulp and paper industry

The invention discloses a production device of viscose fiber dyeing agent vat brown BR. The production device mainly comprises a mixer (F101), a reaction kettle (D101), a suction filter (L101), a vacuum rake dryer (L102), a drum type reactor (D102), a dilution kettle (D103), a filter press (L103), an oxidation kettle (D104), a suction filter (L104), an acid boiling kettle (D106), a filter press (L105), a sanding kettle (D107), a spray dryer ( L106) and a blender (F101), wherein the suction filter (L101) is respectively connected with the reaction kettle (D101) and the vacuum rake dryer (L102),the filter press (L103) is respectively connected with the dilution kettle (D103) and the oxidation kettle (D104), and the mixer (F101) has a full volume of 4.23-4.31 m3.

Owner:CHENGDU AO KA TE TECH CO LTD

Vitamin K3 drug intermediate 2-menaquinone synthesis method

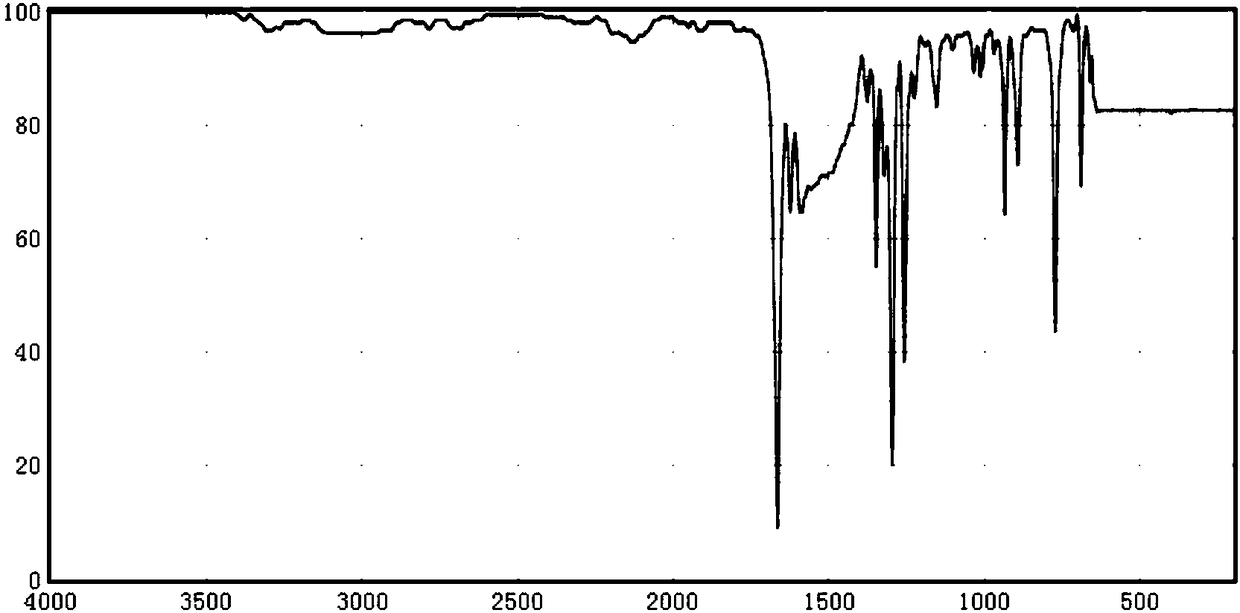

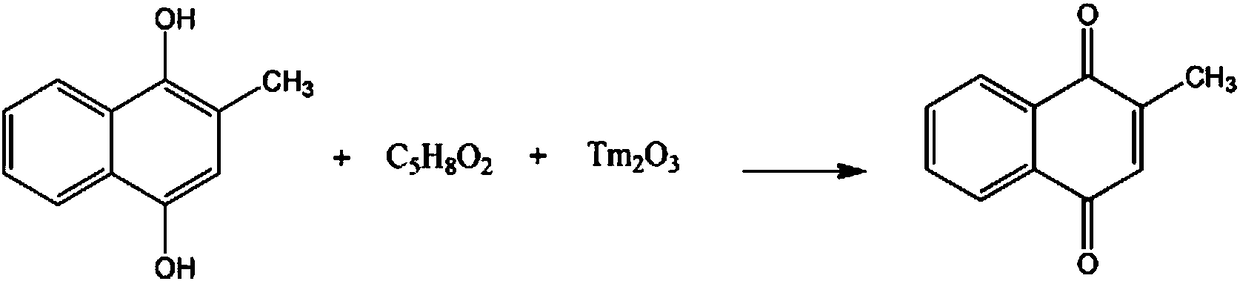

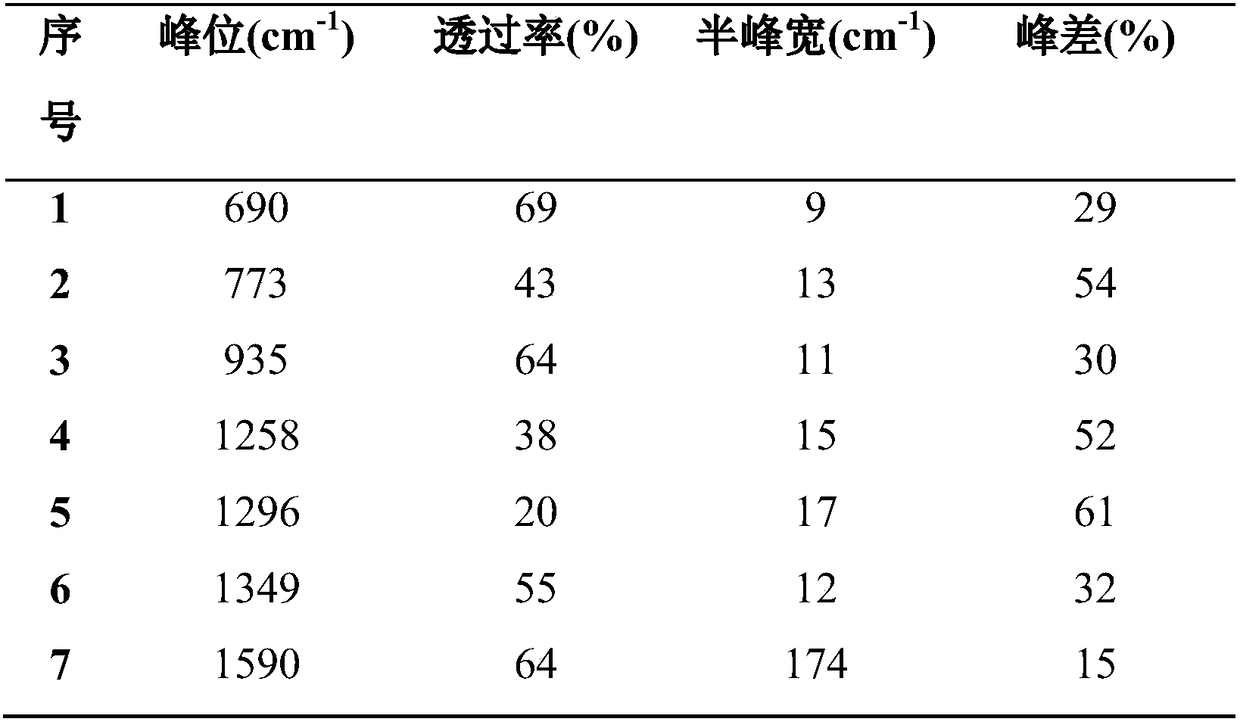

InactiveCN108238880AReduce pollutionReduction of intermediate links in the reactionQuinone preparation by oxidationQuinone separation/purificationVitamin K31-Propanol

The invention discloses a vitamin K3 drug intermediate 2-menaquinone synthesis method, which comprises: adding 1,4-dihydroxy-2-methyl naphthalene and a potassium chloride solution in a reaction container, increasing the temperature of the solution, controlling the stirring speed, adding an acetylacetone solution, carrying out a reaction, adding thulium oxide in batches, increasing the temperatureof the solution, carrying out a reaction for 60-90 min, adding a potassium sulfate solution, reducing the temperature to 10-16 DEG C, carrying out standing layering, adding an oxalic acid solution, adjusting the pH value to 5-6, washing with a 3-chloro-1-propanol solution, washing with a chlorohexane solution, re-crystallizing in a sulfuryl chloride solution, and dehydrating with a dehydrating agent to obtain the finished product 2-menaquinone.

Owner:CHENGDU QIESITE TECH CO LTD

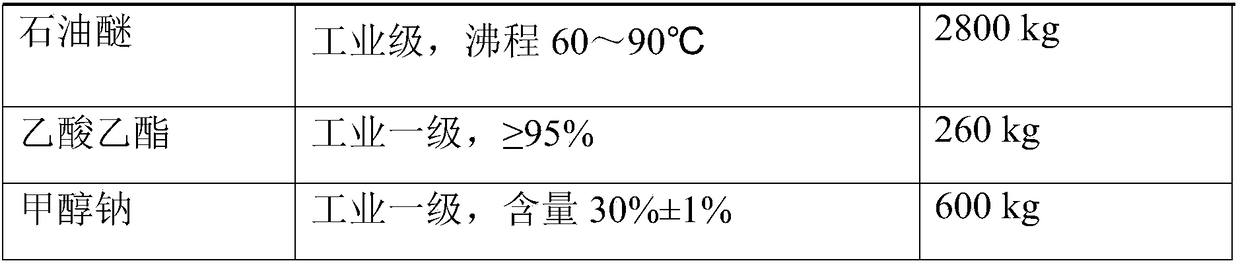

Production device of hindered phenol antioxidant 1010

InactiveCN108238940AReduction of intermediate links in the reactionLow reaction temperatureOrganic compound preparationCarboxylic acid esters preparationDissolutionPhenol

The invention discloses a production device of hindered phenol antioxidant 1010. The production device mainly comprises a catalytic reaction kettle (D101), an isobutylene gasification tank (F101), analkylation kettle (D102), an alkylation water washing kettle (L101), a toluene storage tank (F102), condensers (C101-C107), a rectification kettle (E101), a phenol storage tank (F103), a 2, 4 isomer storage tank (F104), an ortho storage tank (F105), a front and rear fraction storage tank (F106), a finished product crystallization kettle (D105), a filter (L108), a crude ester dissolution kettle (L107), a finished product water washing tank (L106), a petroleum aldehyde storage tank (F109), a dimethyl sulfoxide storage tank (F108), a finished product water washing kettle (D104), centrifuges (L103-L105), a methyl esterification reaction kettle (D103), a separator (L102) and a 2, 6 isomer storage tank (F107), wherein the reaction kettle (D101) has an inner pot diameter of 730-760 mm.

Owner:CHENGDU WEI & SI TECH CO LTD

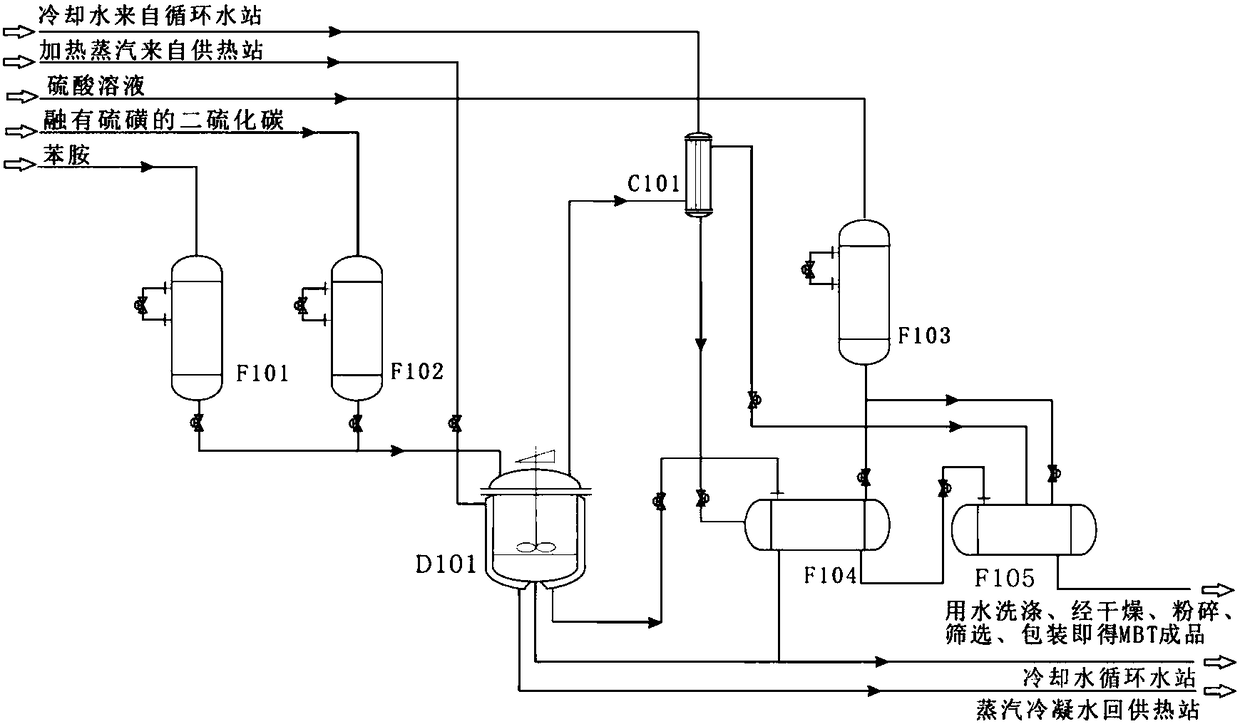

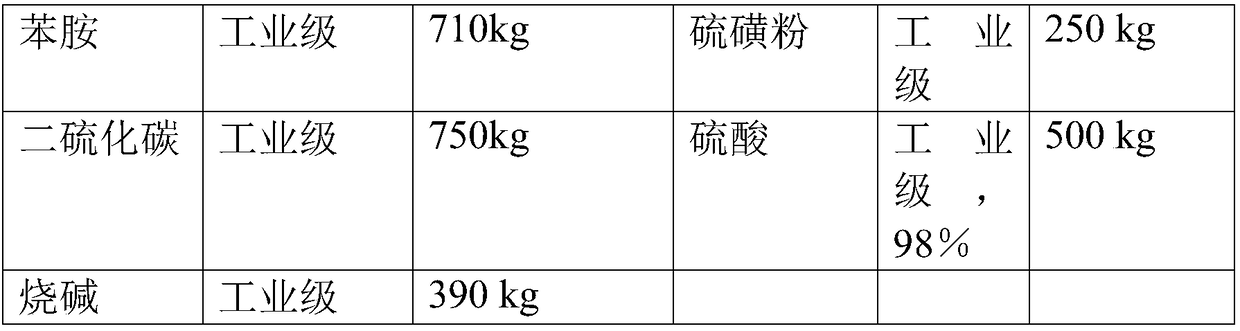

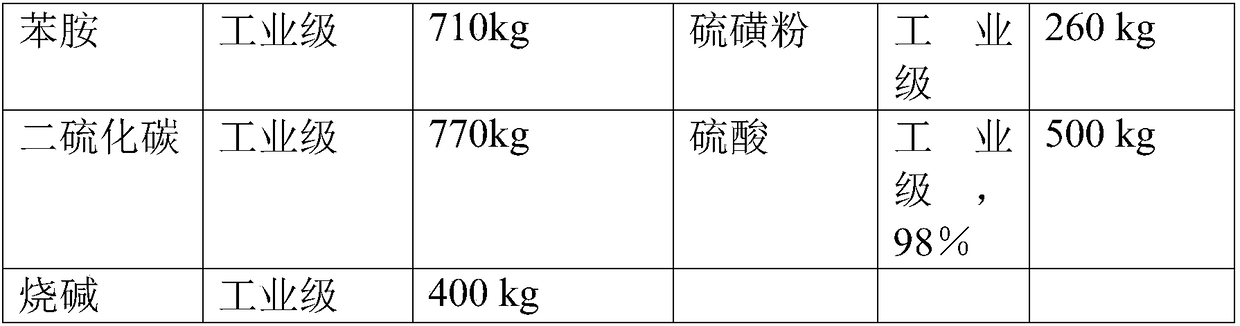

Production apparatus for vulcanization accelerator 2-mercaptobenzothiazole

InactiveCN108239041AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryTransportation and packagingRefluxVulcanization

The invention provides a production apparatus for the vulcanization accelerator 2-mercaptobenzothiazole. The production apparatus mainly comprises a storage tank 1 (F101), a reaction vessel (D101), astorage tank 2 (F102), a dissolving tank 1 (F104), a reflux condenser (C101), a storage tank 3 (F103) and a dissolving tank 2 (F105), wherein the storage tank 1 (F101) is connected with the reaction vessel (D101); the storage tank 2 (F102) is connected with the reaction vessel (D101); the reflux condenser (C101) is connected with the reaction vessel (D101), the dissolving tank 1 (F104) and the dissolving tank 2 (F105); the storage tank 3 (F103) is connected with the dissolving tank 1 (F104) and the dissolving tank 2 (F105); the reaction vessel (D101) is connected with the dissolving tank 1 (F104); the dissolving tank 1 (F104) is connected with the dissolving tank 2 (F105); and the storage tank 1 (F101) has a nominal volume of 5.2-5.5 m<3>.

Owner:CHENGDU PU LAI & TECH CO LTD

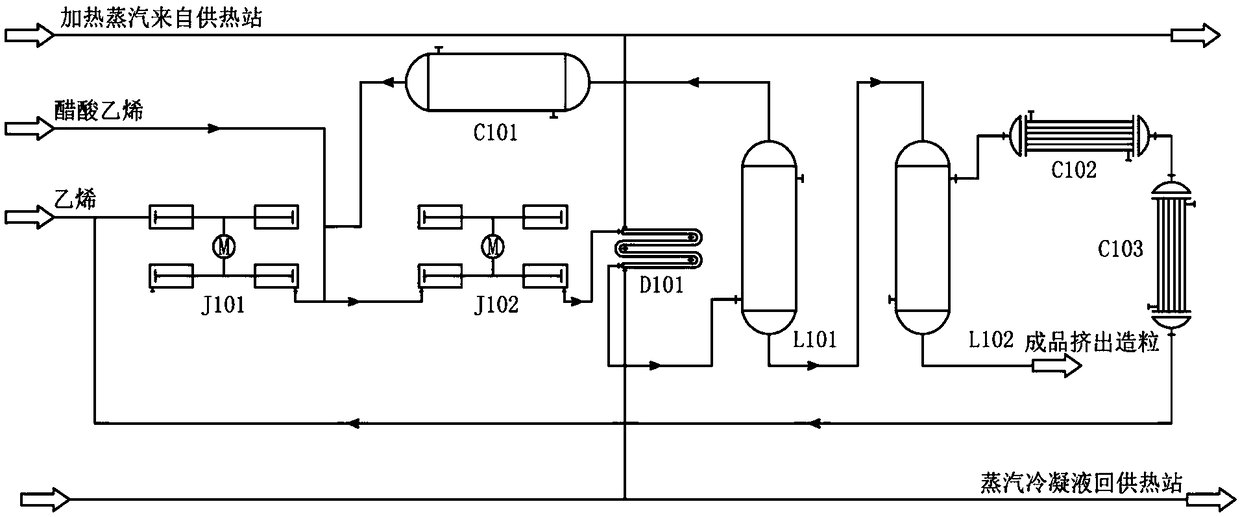

Device for producing ethylene-vinyl acetate copolymer

InactiveCN108239207AReduction of intermediate links in the reactionLow reaction temperatureEthylene productionEngineeringHigh pressure

Provided is a device for producing ethylene-vinyl acetate copolymer. The device mainly includes: a primary compressor (J101), a secondary compressor (J102), a tubular reactor (D101), a high pressure circulating cooler (C101), a high pressure separator (L101), a low pressure separator (L102), a water cooler (C102) and a cooling device (C103), wherein the tubular reactor (D101) is connected with thesecondary compressor (J102) and the high pressure separator (L101) respectively, the low pressure separator (L102) is connected with the high pressure separator (L101) and the water cooler (C102) respectively, and the tubular reactor (D101) has a nominal volume of 320-350 L.

Owner:CHENGDU SI BO LI TECH CO LTD

Production device of viscose fiber colorant chrysophenine GX

InactiveCN108238993AReduction of intermediate links in the reactionLow reaction temperatureDisazo dyesSulfonic acids salts preparationFiberPolymer science

The invention discloses a production device of a viscose fiber colorant chrysophenine GX. The production device mainly comprises a storage tank (F101), a storage tank (F102), a dissolving tank (F103),a storage tank (F104), a storage tank (F105), a condenser (C101), a crusher (L104), a filter press (L102), a dryer (L103), a mixing machine (L105), a diazotization kettle (D101), a coupling kettle (D102), a suction filter (L101), a pulping kettle (D103), a chloroethane steel cylinder (F106), a buffer tank (F107), an ethylation kettle (D104), a distilling kettle (D105) and a salting-out kettle (D106), wherein the nominal volume of the storage tank (F102) is 3.3-3.6 m<3>.

Owner:CHENGDU AO KA TE TECH CO LTD

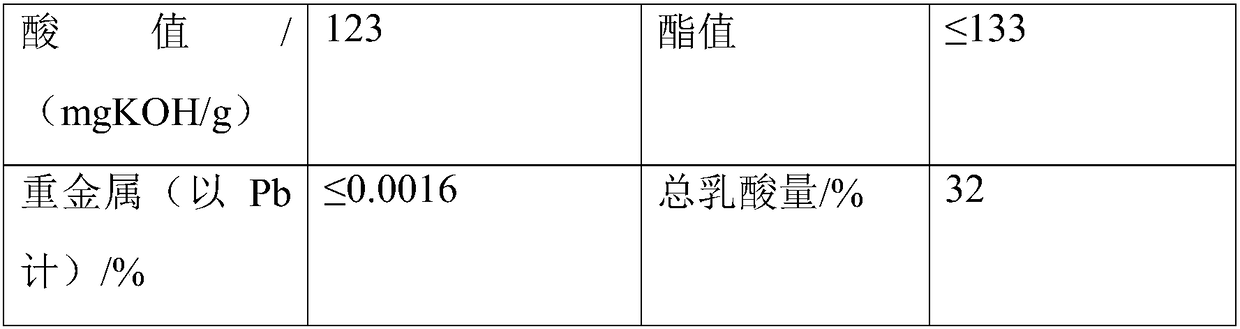

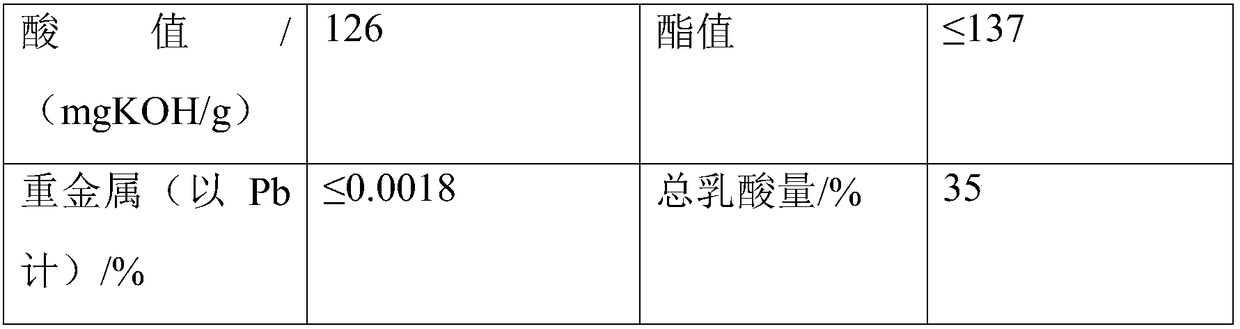

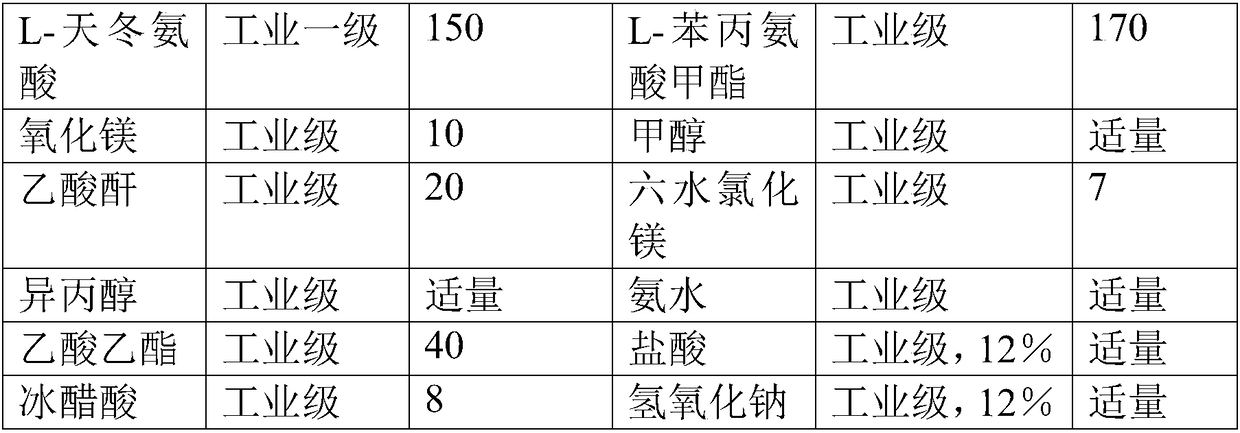

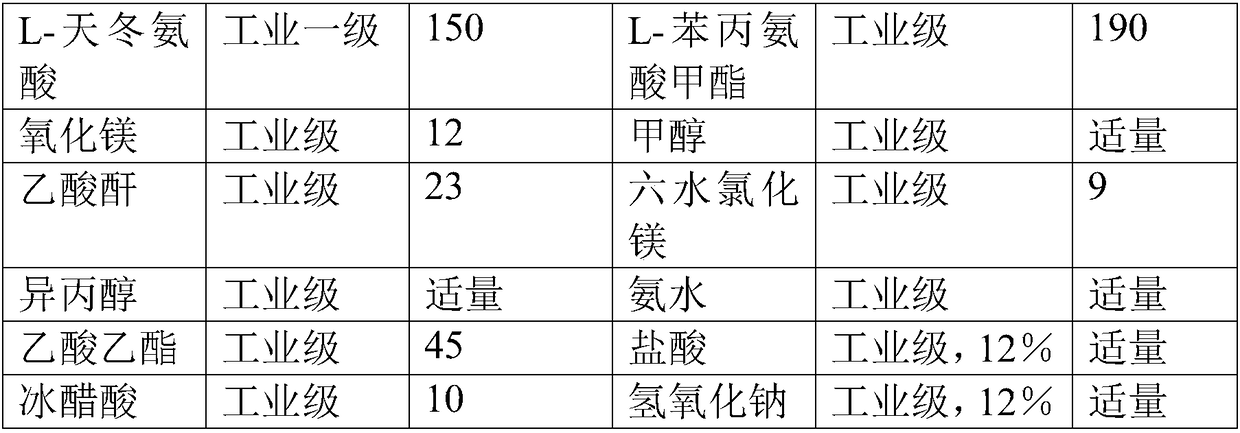

Production method of sodium stearoyl lactylate stabilizer

InactiveCN108503541AReduction of intermediate links in the reactionLow reaction temperatureOrganic compound preparationCarboxylic acid esters preparationEthyl acetateStearic acid

The invention discloses a production method of a sodium stearoyl lactylate stabilizer. The production method mainly comprises the following steps of adding lactic acid in a reactor, performing decompression to 30-33kPa, performing dehydration reaction for 90-120mins under the condition with the temperature being 90-96 DEG C, then adding stearic acid and calcium carbonate in the reactor, performingthermal insulation at 130-140 DEG C under inert gas nitrogen protection, performing esterification reaction for 2-3h, performing decoloration and cooling on a material, washing the material with a dichloromethane solution for 80-100mins, performing recrystallization in an ethyl acetate solution, and performing dehydration with a dehydrating agent to obtain a finished product.

Owner:CHENGDU MO NI TA TECH CO LTD

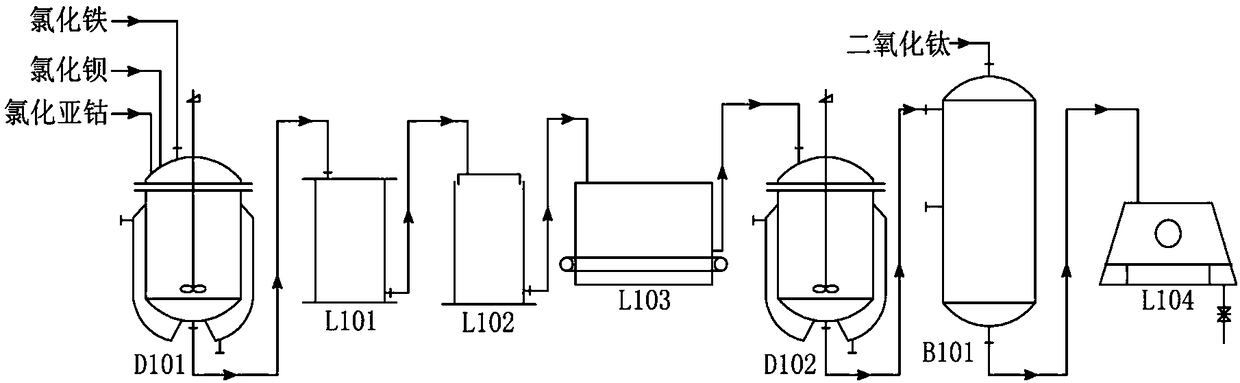

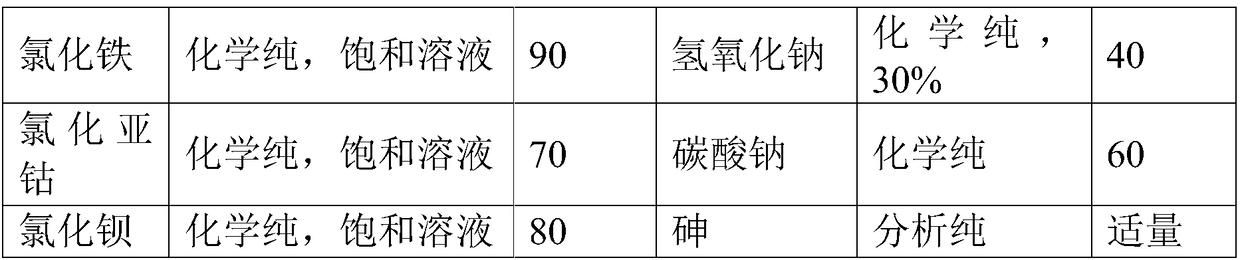

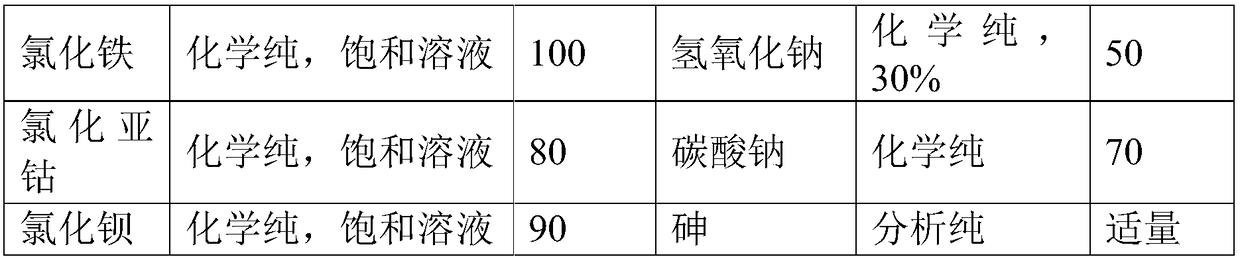

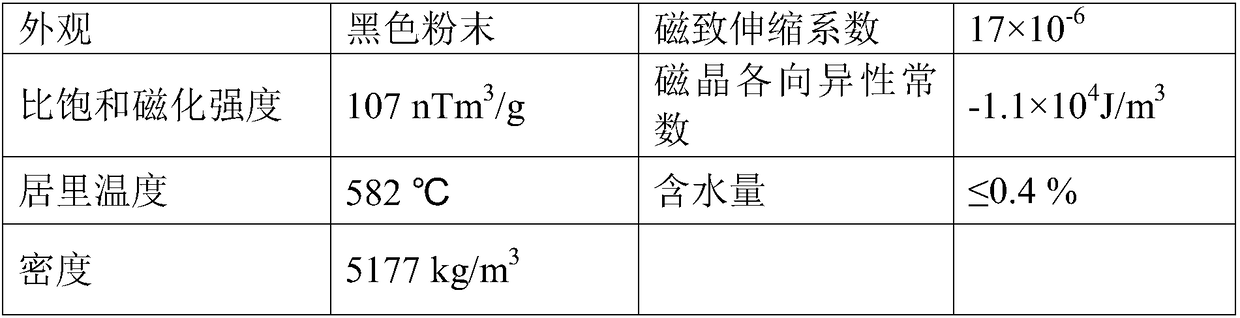

Production device of Co-Ti barium ferrite magnetic powder

InactiveCN108238789AWell mixedReduction of intermediate links in the reactionInorganic material magnetismInductances/transformers/magnets manufactureBall millScrubber

The invention discloses a production device of Co-Ti barium ferrite magnetic powder. The production device mainly comprises a mixing kettle (D101), a mixing kettle (D102), a filter (L101), a scrubber(L102), a dryer (L103), a ball mill (L104) and a sintering furnace (B101), wherein the filter (L101) is connected with the mixing kettle (D101) and the scrubber (L102) respectively, the mixing kettle(D102) is connected with the dryer (L103) and the sintering furnace (B101) respectively, and the nominal volume of the mixing kettle (D101) is 1300-1500L.

Owner:CHENGDU MI ER DUN TECH CO LTD

Device for producing antioxidant 2,6-di-tert-butyl-4-methylphenol

InactiveCN108238851AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryOrganic compound preparationAlkyl transferDistillation

Provided is a device for producing an antioxidant 2,6-di-tert-butyl-4-methylphenol. The device includes: a storage tank (F101), a bromobutene gasification tank (F102), a raw material pump (J101), an alkylation neutralization reactor (D101), transfer pumps (J102-J105), an alkylation water washing kettle (L101), centrifuges (L102, L104), a melting water washing kettle (L103), a recrystallization reactor (D102), a drying oven (L105), an ethanol distillation tower (E101), a condenser (C101) and an ethanol storage tank (F103), wherein the storage tank (F101) is used for storing sulfuric acid, the transfer pump (J103) is connected with the alkylation water washing kettle (L101) and the centrifuge (L102) respectively, the transfer pump (J104) is connected with the recrystallization reactor (D102)and the centrifuge (L104) respectively, and the storage tank (F101) has a full volume of 2.3-2.5 m<3>.

Owner:CHENGDU WEI & SI TECH CO LTD

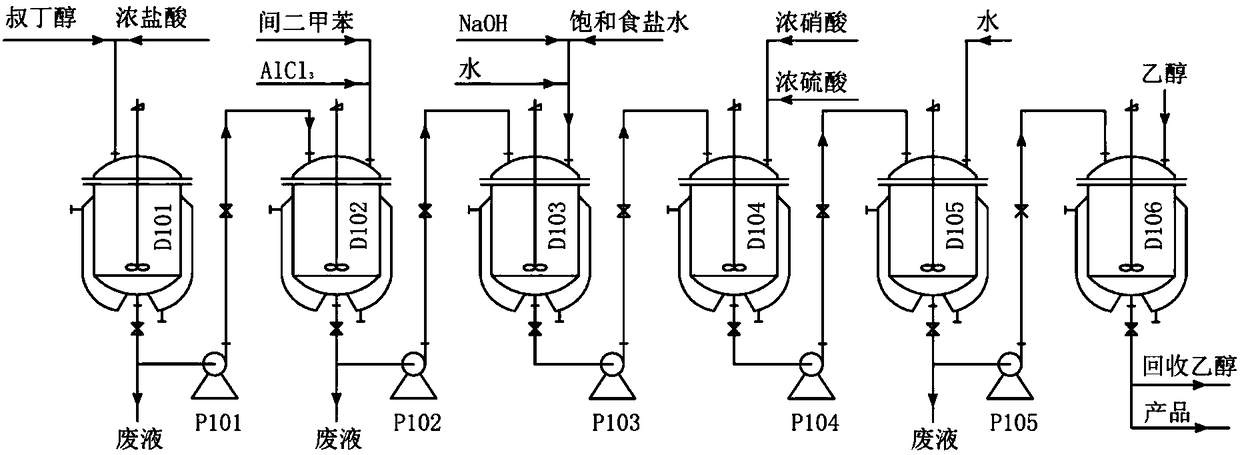

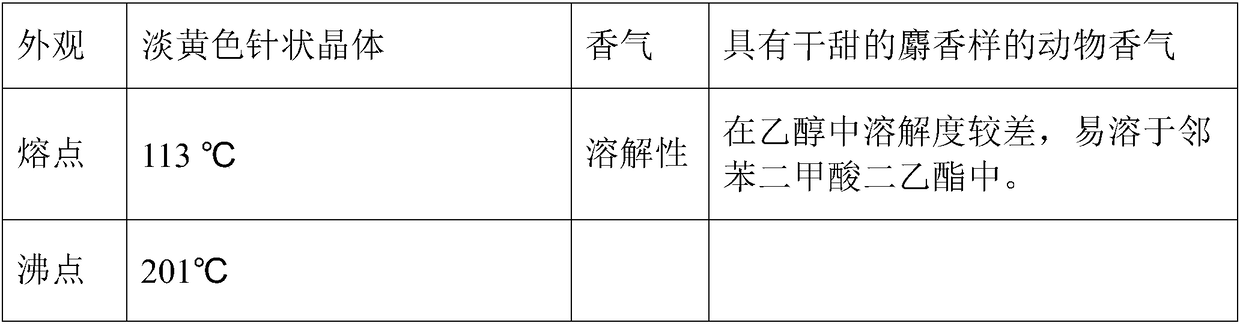

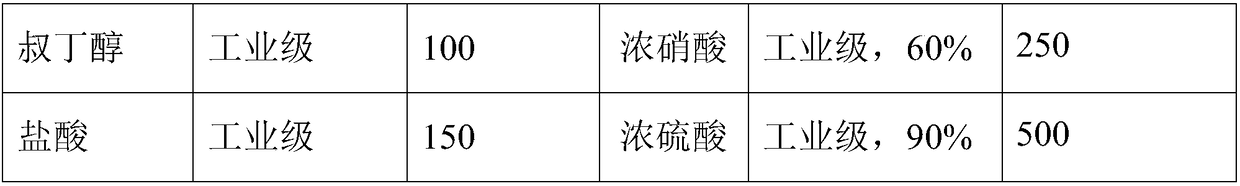

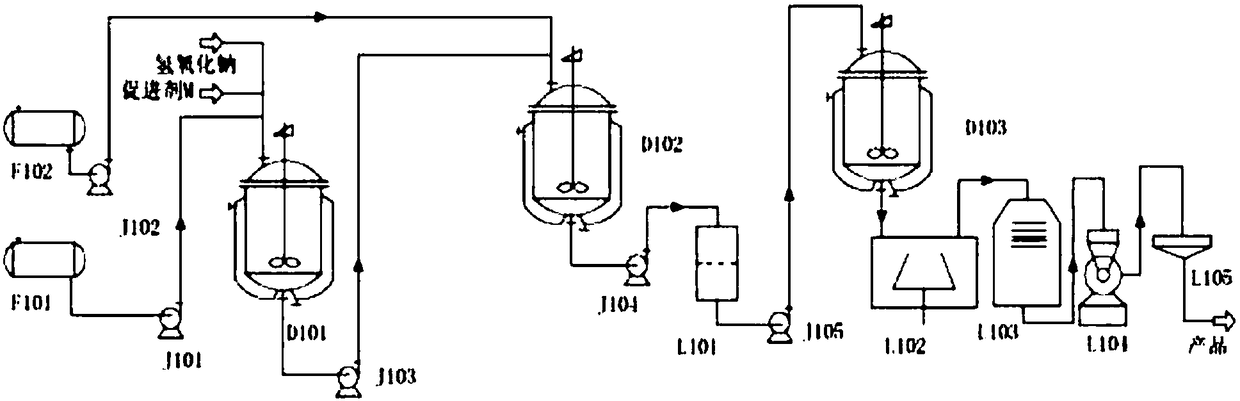

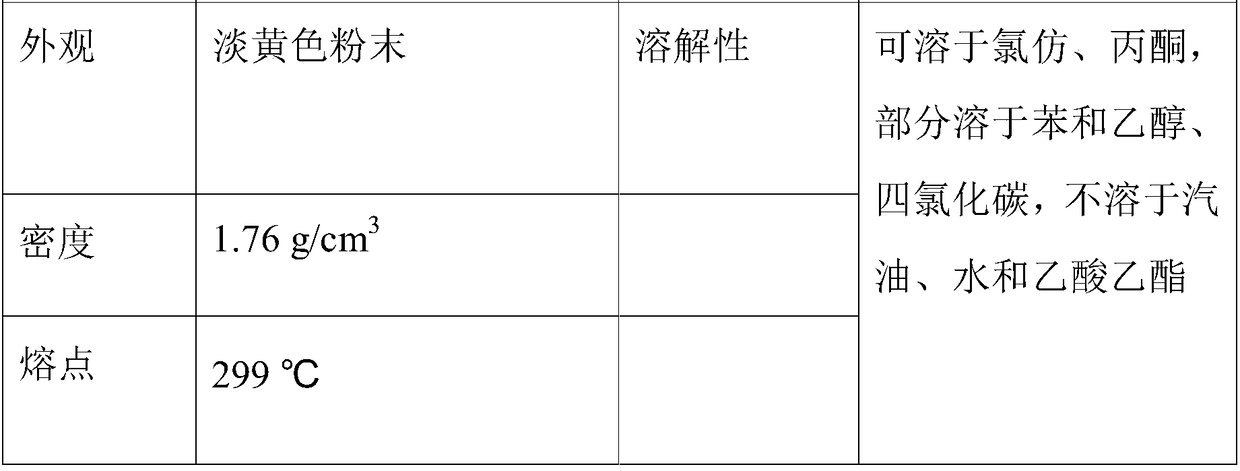

Production device for 2,4,6-trinitro-3,3-dimethyl-5-tert-butylbenzene

InactiveCN108238954AReduction of intermediate links in the reactionLow reaction temperatureHydrocarbonsHydrocarbon by hydrocarbon and non-hydrocarbon condensationTert-butylbenzeneCrystallization

The invention discloses a production device for 2,4,6-trinitro-3,3-dimethyl-5-tert-butylbenzene. The production device mainly includes a chlorination tank (D101), a condensation tank (D102), a neutralization water washing tank (D103), delivery pumps (P101-P105), a nitrification tank (D104), a water washing tank (D105), and a crystallization tank (D106), wherein one delivery pump (P101) is connected with the chlorination tank (D101) and the condensation tank (D102), one delivery pump (P104) is connected with the nitrification tank (D104) and the water washing tank (D105), and one delivery pump(P103) has an impeller diameter of 107-112mm.

Owner:成都盛金缘餐饮文化传播有限公司

Production device of vulcanization accelerator zinc 2-mercaptobenzothiazole

InactiveCN108239042AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryVulcanizationSulfate

The invention discloses a production device of a vulcanization accelerator zinc 2-mercaptobenzothiazole. The production device mainly comprises a storage tank (F101), a storage tank (F102), raw material pumps (J101 and J102), a reaction kettle (D101), a reaction kettle (D102), conveying pumps (J103-J105), a water washing kettle (D103), a filter (L101), a centrifuge (L102), a dryer (L103), a crusher (L104) and a vibrating screen (L105), wherein the storage tank (F101) is used for storing deionized water, the storage tank (F102) is used for storing a zinc sulfate solution, the conveying pump (J103) is connected with the reaction kettle (D101) and the reaction kettle (D102) respectively, the conveying pump (J105) is connected with the filter (L101) and the water washing kettle (D103) respectively, and the seal head thickness of the storage tank (F102) is 7-9mm.

Owner:CHENGDU WEI & SI TECH CO LTD

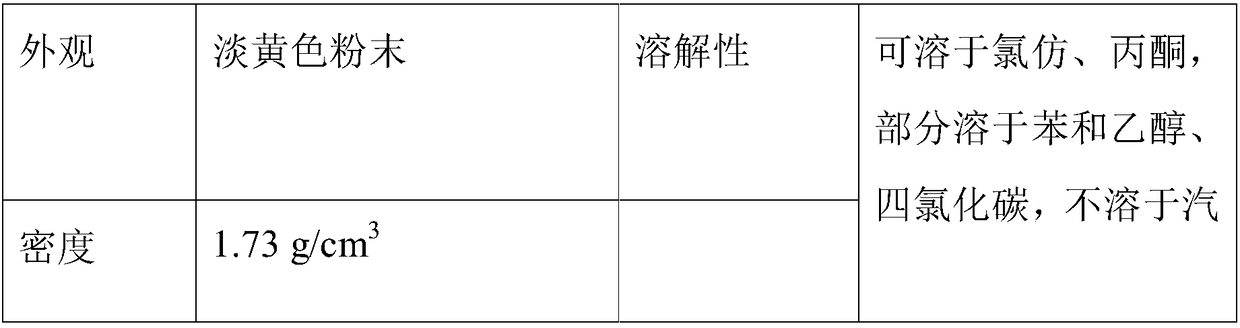

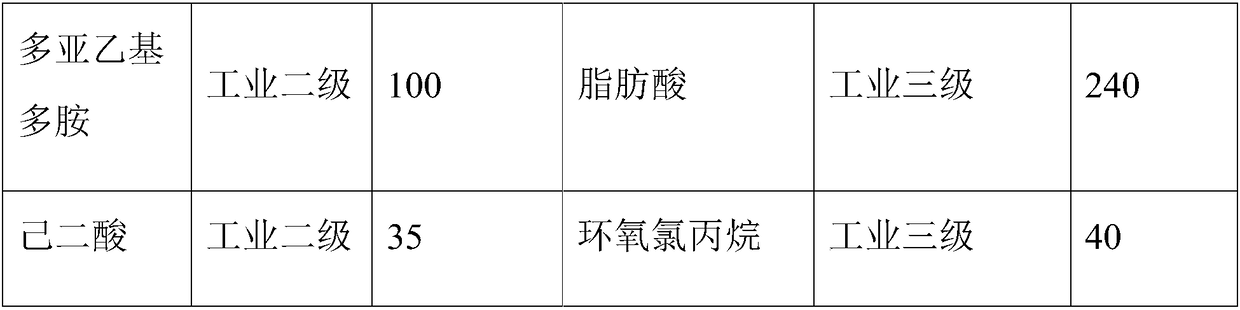

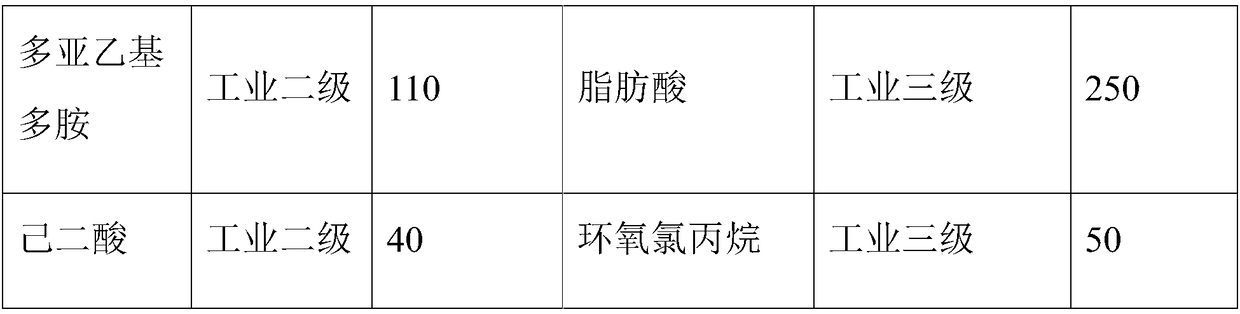

Production device for modified polyamide-polyamine

InactiveCN108239283AReduction of intermediate links in the reactionLow reaction temperatureWater-repelling agents additionPolyamideAdipic acid

The invention provides a production device for modified polyamide-polyamine. The production device mainly comprises: a storage tank (F101), a condensation kettle (D101), a storage tank (F102), a firstmodifying kettle (D102), a storage tank (F103), a dilution kettle (D103), a storage tank (F104), a secondary modifying kettle (D104), a storage tank (F105), a stabilizing groove (L101) and feed pumps(J101 to J104), wherein the storage tank (F101) is used to store polyethylene polyamine; the storage tank (F102) is used to store adipic acid; the storage tank (F103) is used to store fatty acid; thestorage tank (F104) is used to store deionized water; the storage tank (F105) is used to store epichlorohydrin; a feed pump (J101) is respectively connected with the condensation kettle (D101) and the first modifying kettle (D102); a feed pump (J103) is respectively connected with the dilution kettle (D103) and the secondary modifying kettle (D104); and the storage tank (F102) has a nominal volume of 2.7 to 2.9 m3.

Owner:CHENGDU PA LUO AO TECH CO LTD

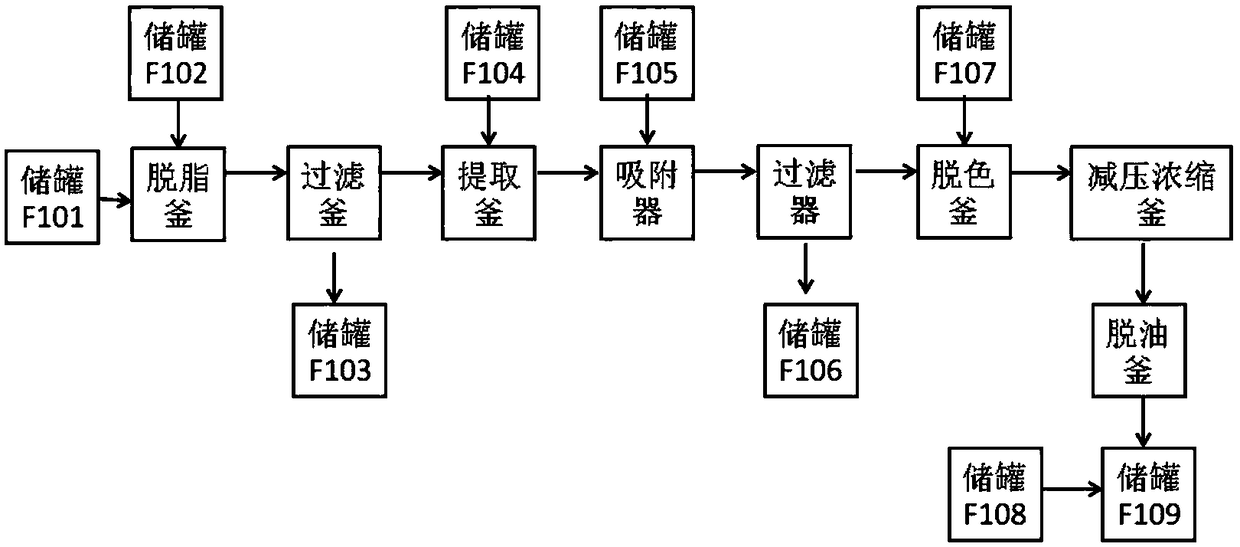

Production device of antioxidant phospholipid

InactiveCN108239110AReduction of intermediate links in the reactionLow reaction temperatureGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsActivated carbonAntioxidant

The invention discloses a production device of an antioxidant phospholipid. The production device mainly comprises a storage tank F101, a storage tank F102, a storage tank F103, a storage tank F104, astorage tank F105, a storage tank F106, a storage tank F107, a storage tank F108, a storage tank F109, a degreasing kettle, a filtering kettle, an extraction kettle, an adsorber, a filter, a decoloring kettle, a reduced-pressure concentration kettle and an oil removal kettle, wherein the storage tank F101 is used for storing a crude phospholipid raw material; the storage tank F102 is used for storing acetone; the storage tank F103 is used for recycling the filtrate acetone; the storage tank F104 is used for storing an ethanol solution; the storage tank F105 is used for storing aluminum oxide;the storage tank F106 is used for collecting the filter residue; the storage tank F107 is used for storing activated carbon; the storage tank F108 is used for storing acetone; the storage tank F109 is used for storing the finished product; and the cone base thickness of the storage tank F102 is 7-8mm.

Owner:CHENGDU PU LAI & TECH CO LTD

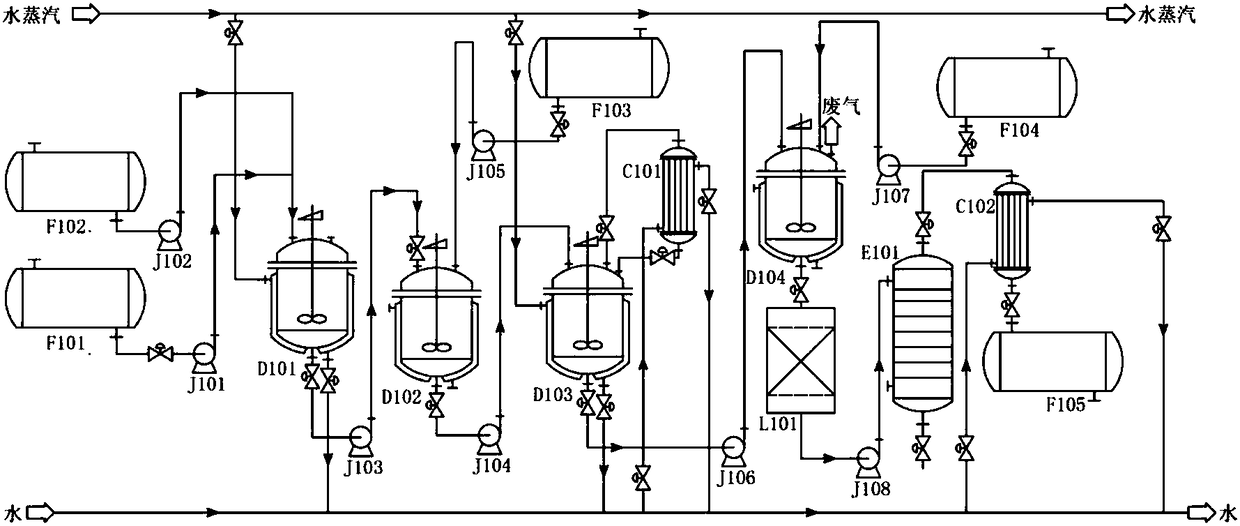

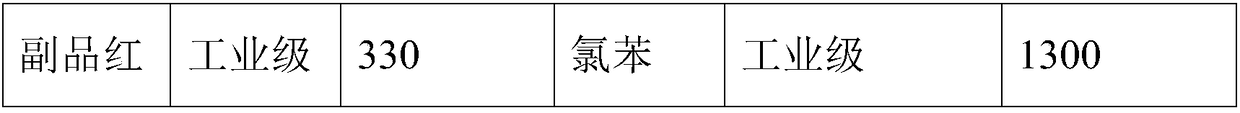

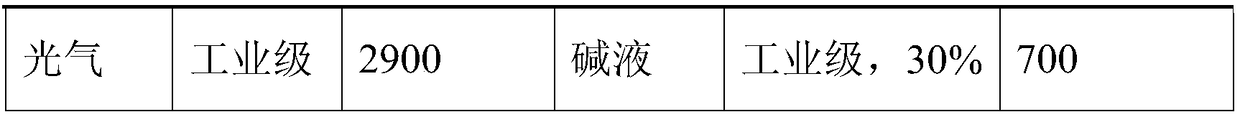

Production device of triphenylmethane triisocyanate

InactiveCN108238980AReduction of intermediate links in the reactionLow reaction temperatureIsocyanic acid derivatives preparationOrganic compound preparationTriphenylmethane triisocyanateChlorobenzene

The invention relates to a production device of triphenylmethane triisocyanate. The production device mainly comprises a low-temperature photochemical kettle (D102), a raw material pump (J101), a rawmaterial pump (J102), a high-temperature photochemical kettle (D103), conveying pumps (J103, J104, J106 and J108), a storage tank (F103), condensers (C101 and C102), a gas expelling kettle (D104), vacuum pump (J105 and J107), a filter (L101), a distillation column (E101), a storage tank (F104), a finished product receiving tank (F105), a storage tank (F101), a storage tank (F102) and a suspensionpreparation kettle (D101), wherein the storage tank (F103) is used for storing phosgene, the storage tank (F104) is used for storing nitrogen, the storage tank (F101) is used for storing chlorobenzene, the storage tank (F102) is used for storing parafuchsin, and the diameter of a water inlet of the raw material pump (J102) is 230-250mm.

Owner:成都麦克贝恩科技有限公司

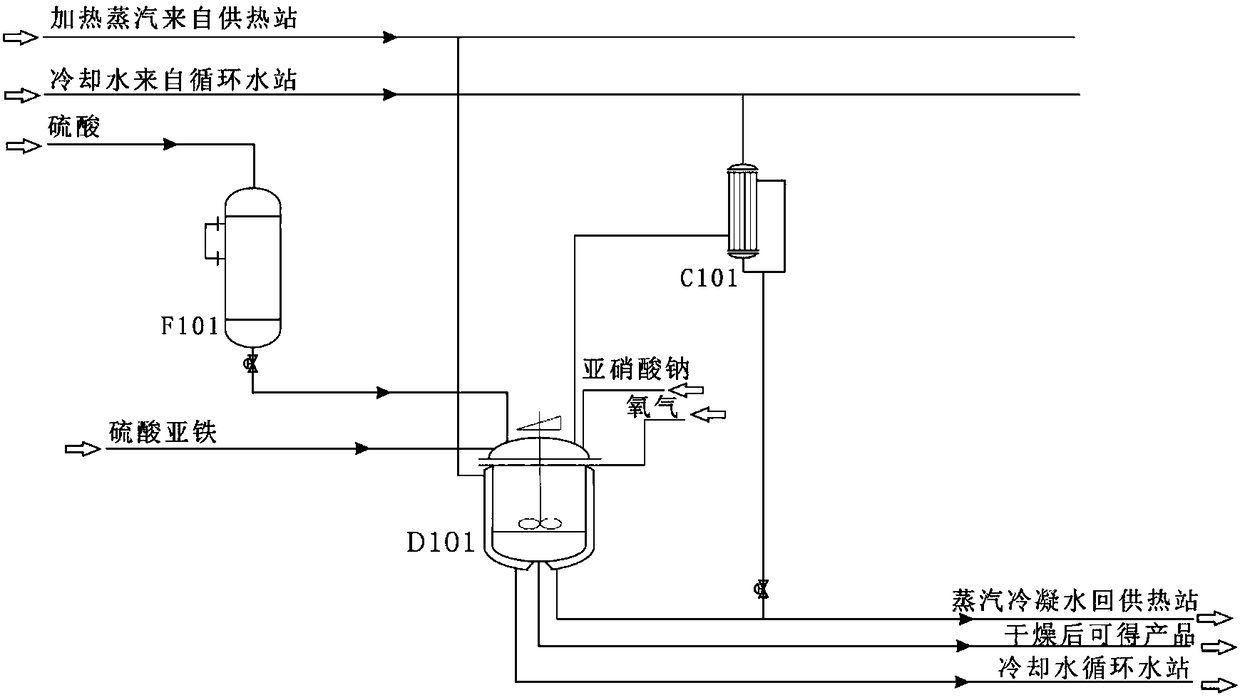

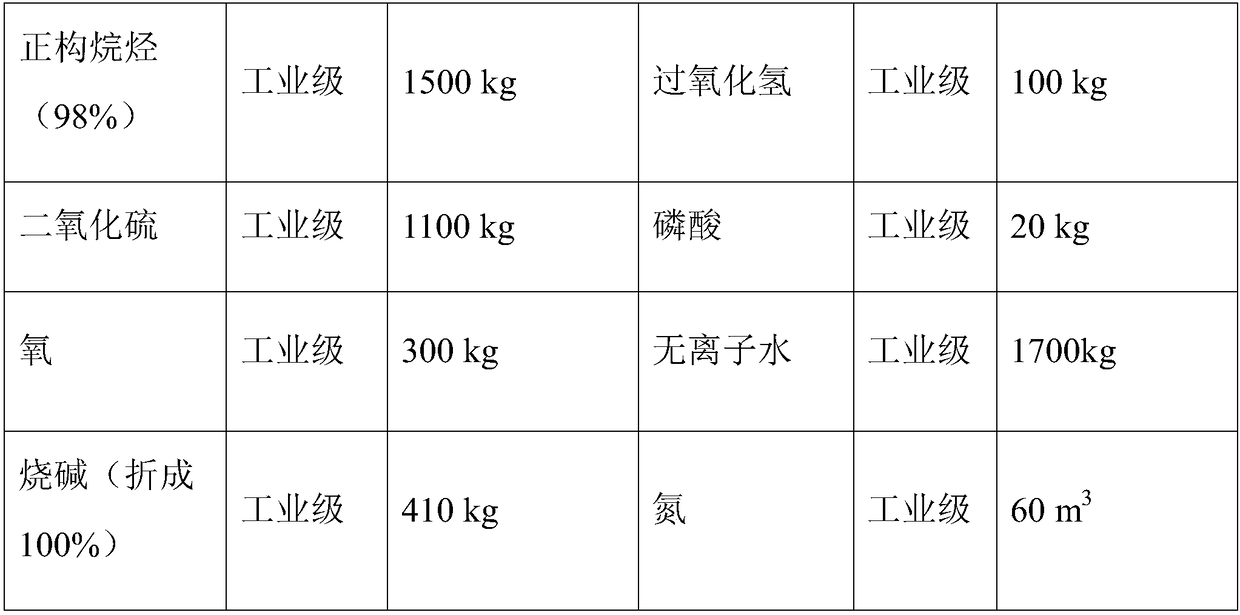

Production apparatus for coagulant polyferric sulfate

InactiveCN108238647AReduction of intermediate links in the reactionLow reaction temperatureIron sulfatesChemical/physical/physico-chemical stationary reactorsLiquid storage tankPolymerization

The invention provides a production apparatus for coagulant polyferric sulfate. The production apparatus mainly comprises a polymerization vessel (D101), a condenser (C101) and a liquid storage tank (F101), wherein the liquid storage tank (F101) is connected with the polymerization vessel (D101); the condenser (C101) is connected with the polymerization vessel (D101); and the polymerization vessel(D101) has a nominal volume of 750-820 L.

Owner:CHENGDU MO NI TA TECH CO LTD

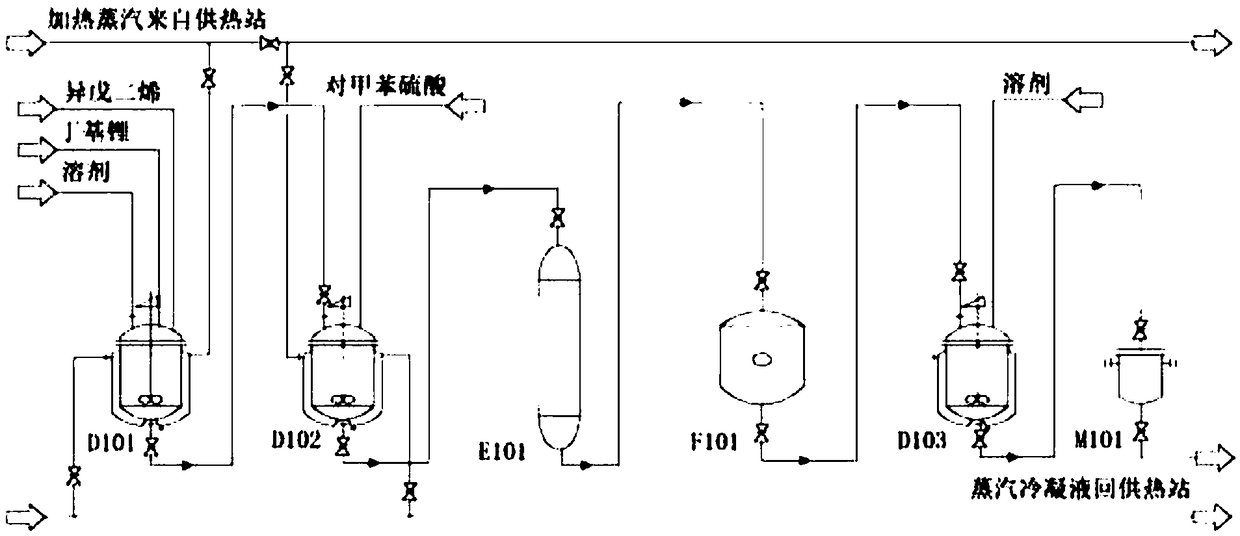

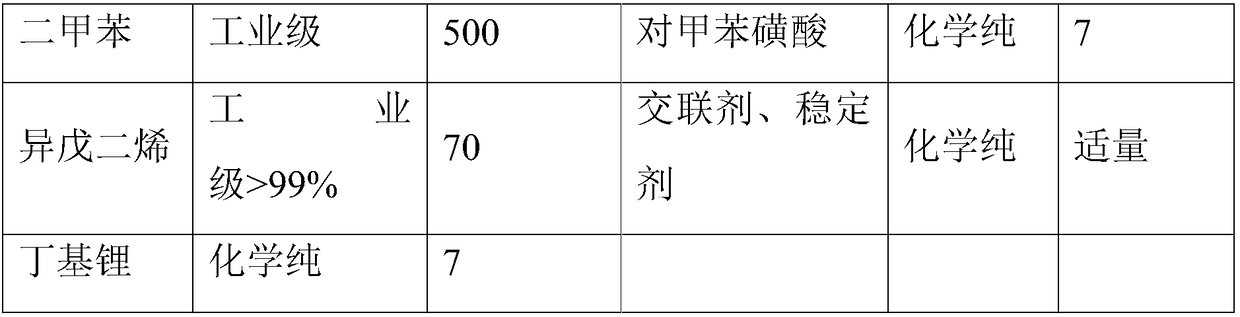

Device for producing cyclized polyisoprene resist

InactiveCN108239206AReduction of intermediate links in the reactionLow reaction temperatureResistProcess engineering

Provided is a device for producing cyclized polyisoprene resist. The device mainly comprises: a polymerization kettle (D101), a cyclization kettle (D102), a washing tower (E101), a concentrator (F101), a glue preparation kettle (D103) and a filter (M101), wherein the washing tower (E101) is connected with the cyclization kettle (D102) and the concentrator (F101) respectively, the glue preparationkettle (D103) is connected with the concentrator (F101) and the filter (M101) respectively, and the polymerization kettle (D101) has a nominal capacity of 630-660 L.

Owner:CHENGDU WEI ER BO DUN TECH CO LTD

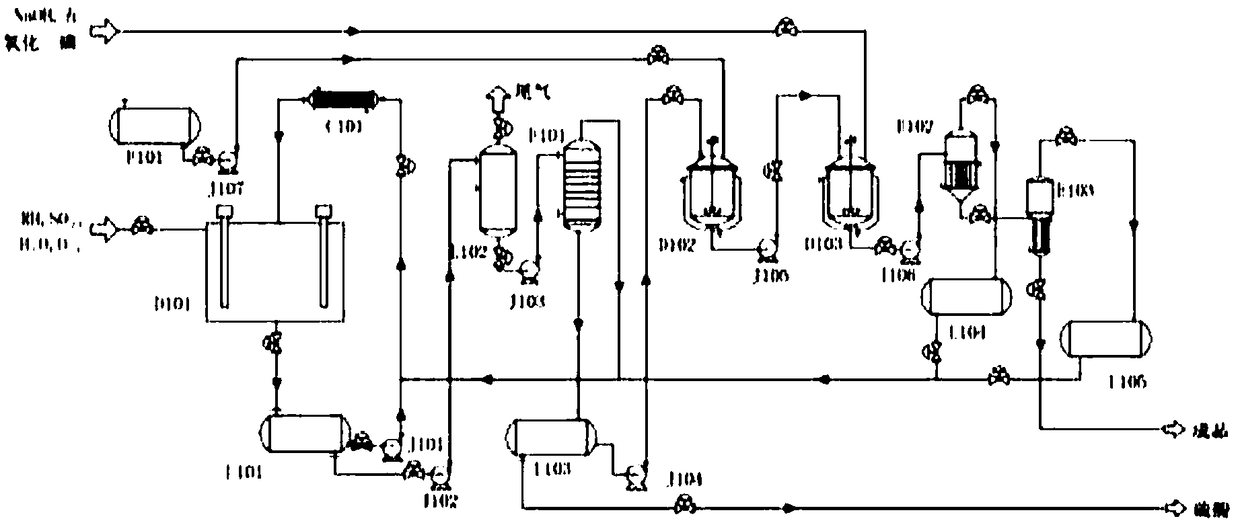

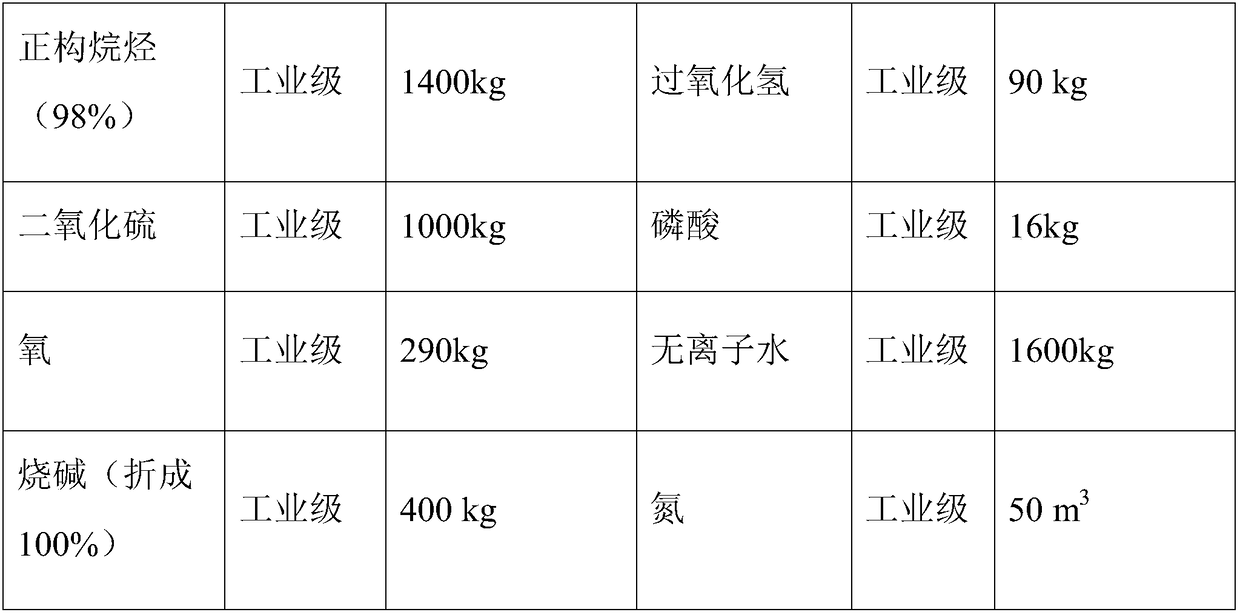

Production device for heat-resistant resin antistatic agent namely secondary alkyl sodium sulfonate

InactiveCN108238985AReduction of intermediate links in the reactionLow reaction temperatureOrganic chemistryOrganic compound preparationSulfonateReflux

The invention provides a production device for a heat-resistant resin antistatic agent namely secondary alkyl sodium sulfonate. The production device mainly comprises: a storage tank (F101), a photochemical reactor (D101), a cooler (C101), a gas-liquid separator (L102), separation tanks (L101 and L103 to L105), a reflux pump (J101), a falling-film evaporation tower (E101), a bleaching tank (D102),a neutralizing tank (D103), delivery pumps (J102 to J107), an evaporator (E102) and a stripping tower (E103), wherein the storage tank (F101) is used to store hydrogen peroxide; a delivery pump (J107) is respectively connected with the storage tank (F101) and the bleaching tank (D102); a delivery pump (J102) is respectively connected with a separation tank (L101) and the gas-liquid separator (L102); and the wall thickness of the drum body of the storage tank (F101) is 7 to 9 mm.

Owner:CHENGDU PA LUO AO TECH CO LTD

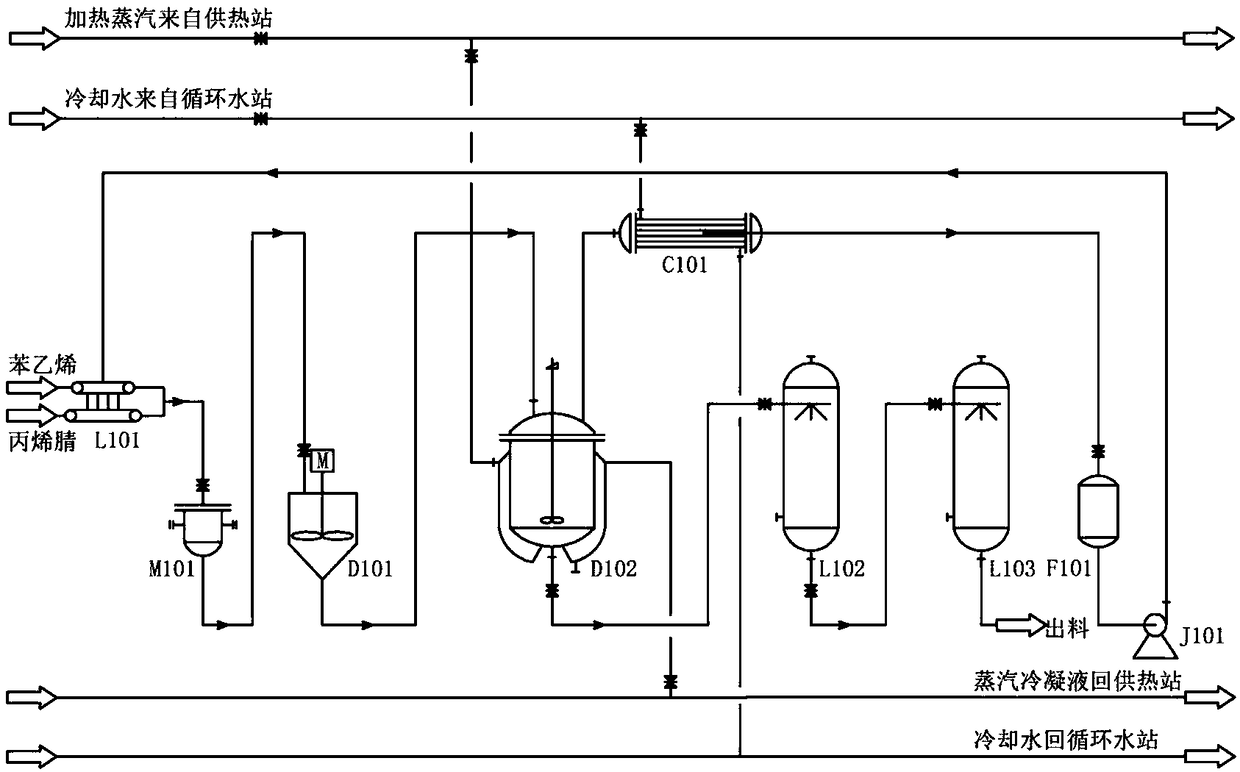

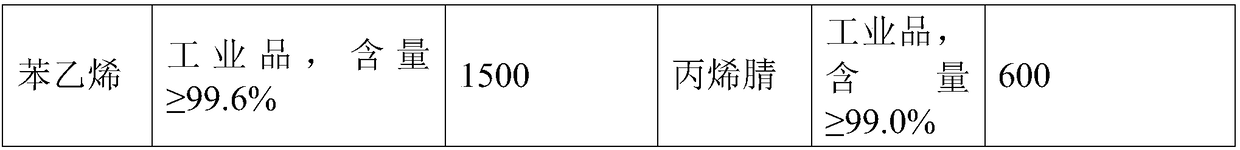

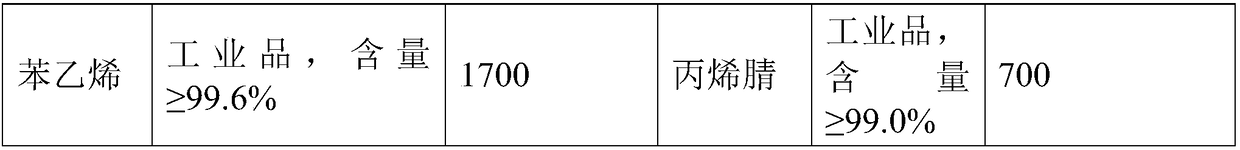

Production apparatus for acrylonitrile-styrene random copolymer

InactiveCN108239187AReduction of intermediate links in the reactionLow reaction temperatureAcrylonitrileProcess engineering

The invention discloses production apparatus for an acrylonitrile-styrene random copolymer. The production apparatus mainly comprises a preheater (L101), a filter (M101), a mixer (D101), a polymerization kettle (D102), a condenser (C101), a devolatilization device (L102), a devolatilization device (L103), a recovery tank (F101), and a feed pump (J101), wherein the mixer (D101) is connected to thefilter (M101) and the polymerization kettle (D102), the devolatilization device (L102) is connected to the polymerization kettle (D102) and the devolatilization device (L103), and the mixer (D101) hasa nominal volume of 330-360L.

Owner:CHENGDU SI BO LI TECH CO LTD

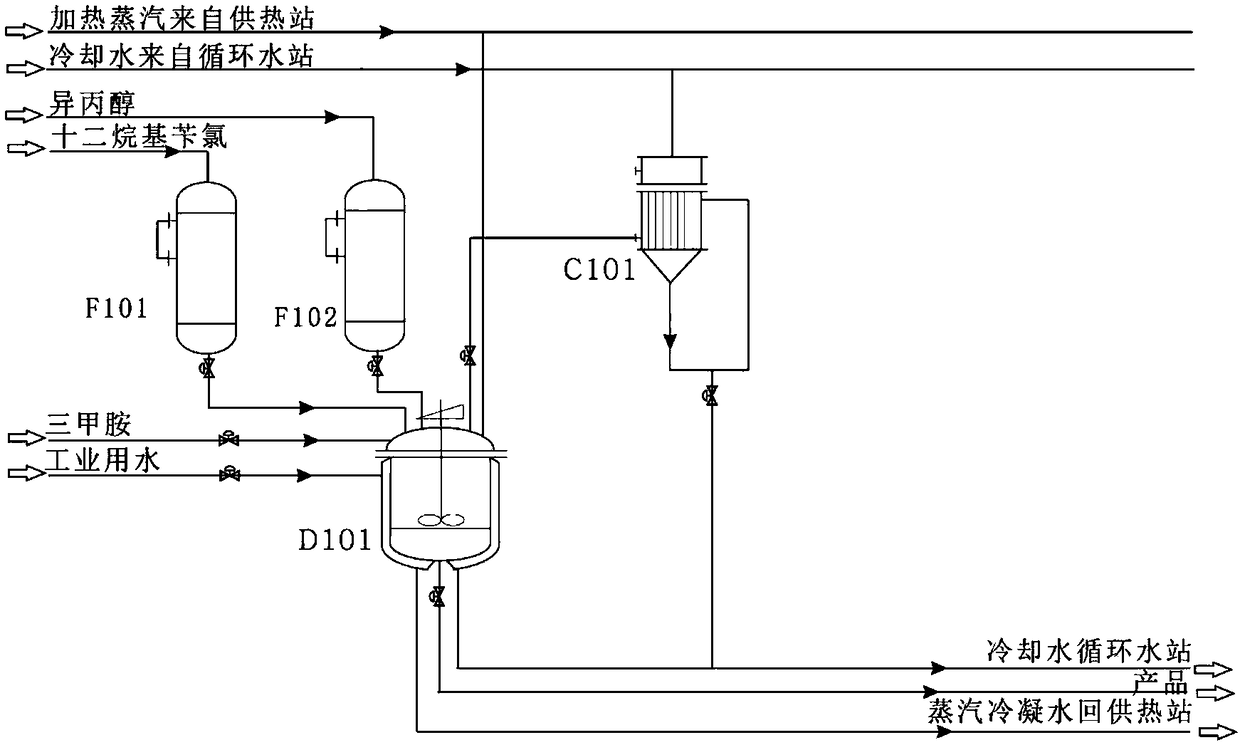

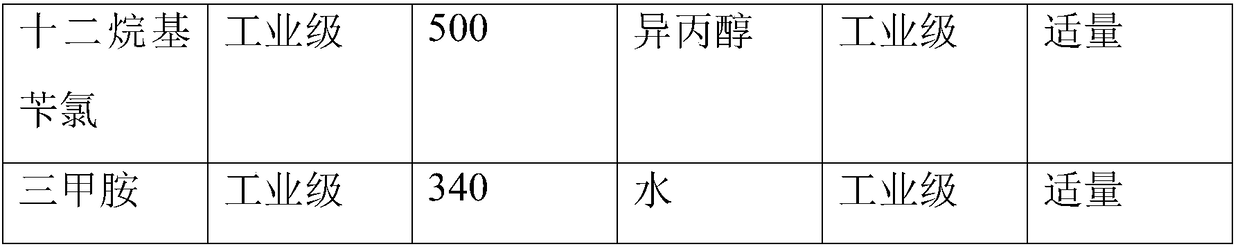

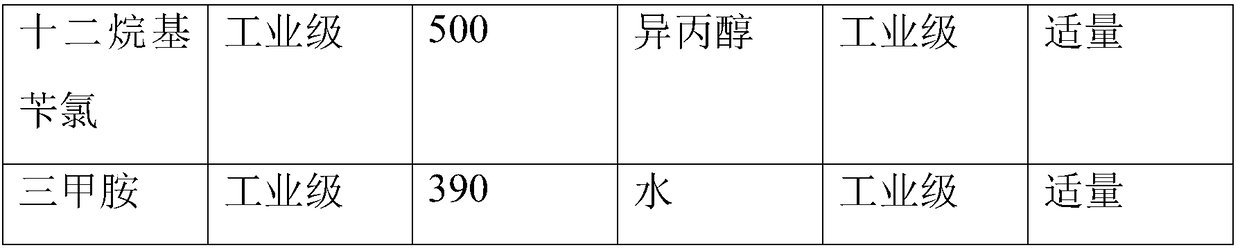

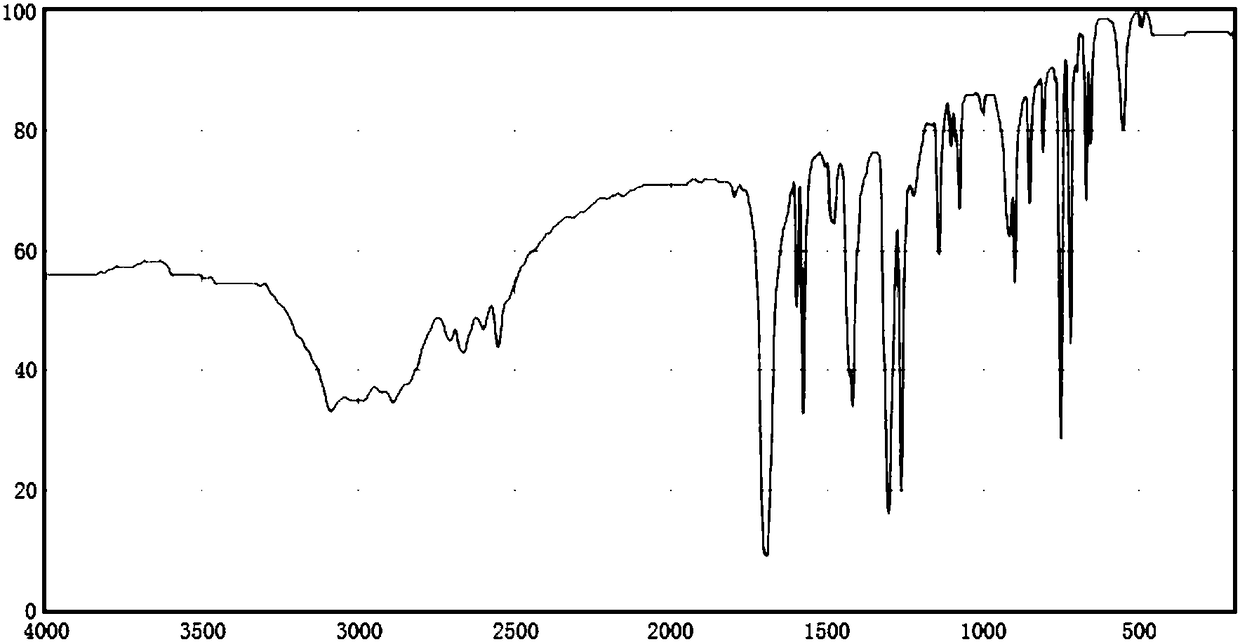

Production device of antistatic agent dodecylbenzyltrimethylammonium chloride

InactiveCN108236902AReduction of intermediate links in the reactionLow reaction temperatureOrganic compound preparationChemical/physical/physico-chemical stationary reactorsRefluxControl engineering

The invention discloses a production device of an antistatic agent dodecylbenzyltrimethylammonium chloride. The production device mainly comprises a reaction kettle (D101), a reflux condenser (C101),a storage tank 1 (F101) and a storage tank 2 (F102). The storage tank 1 (F101) is connected to the reaction kettle (D101), the storage tank 2 (F102) is connected to the reaction kettle (D101), and thereflux condenser (C101) is connected to the reaction kettle (D101). The inner pot of the reaction kettle (D101) has the diameter of 550 to 600 mm.

Owner:CHENGDU MO NI TA TECH CO LTD

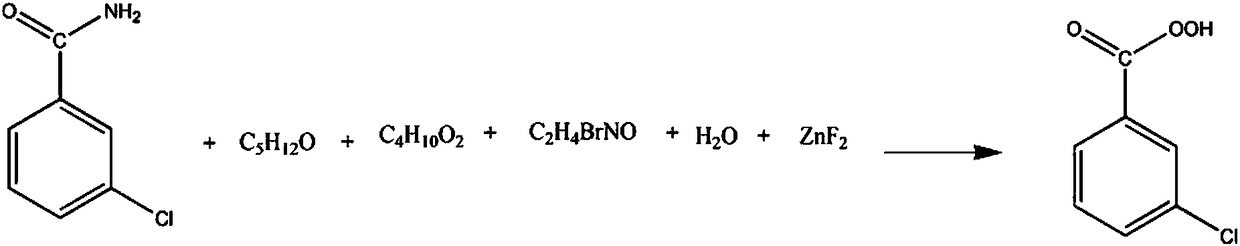

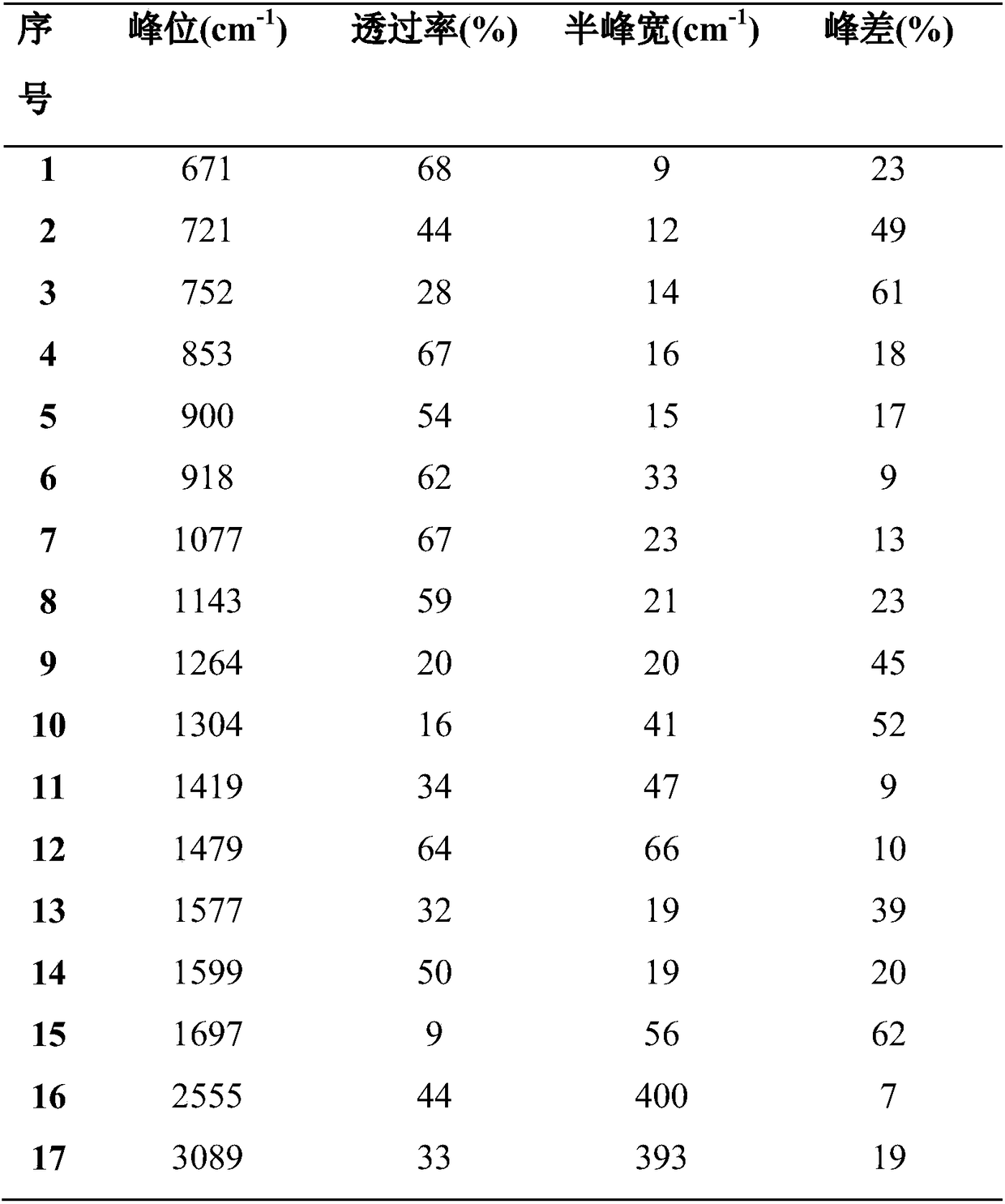

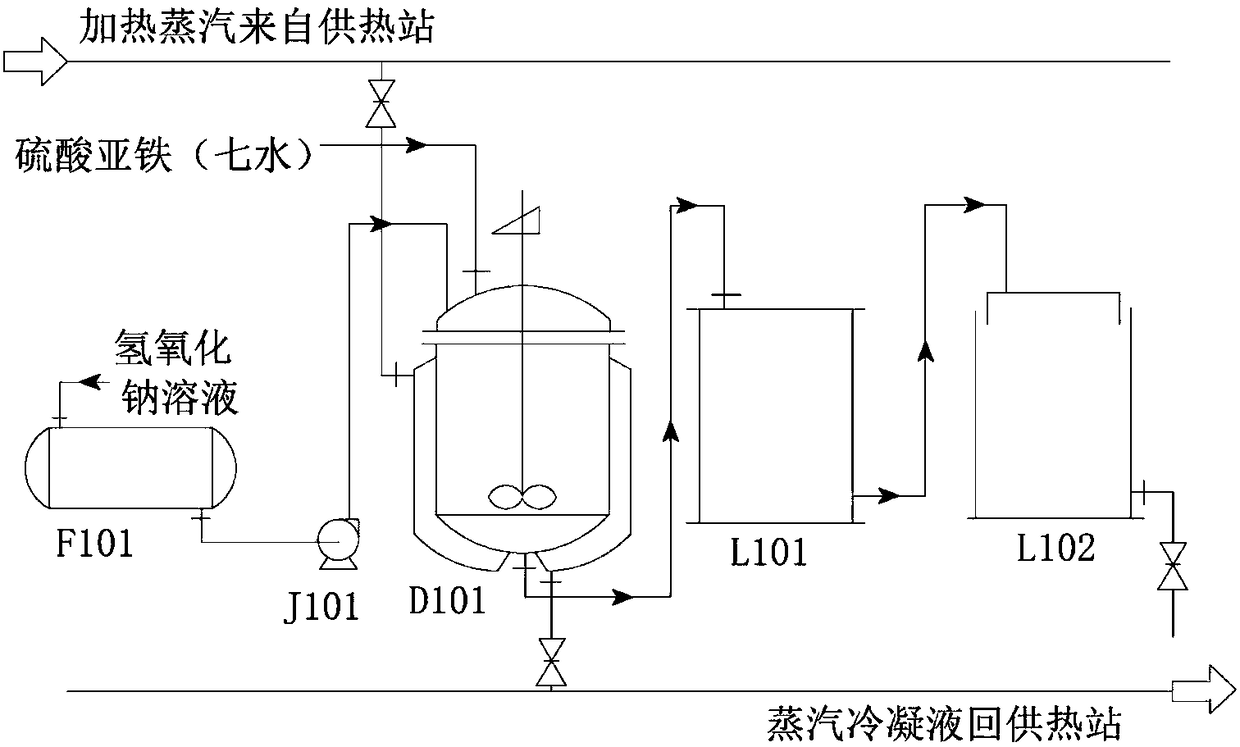

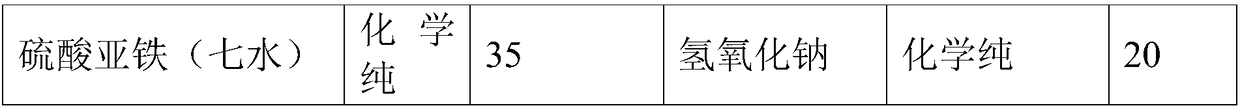

Synthetic method for drug intermediate m-chloroperbenzoic acid

InactiveCN108239009AHealth hazardReduce health hazardsOrganic compound preparationPeroxy compound preparationMeta-Chloroperoxybenzoic acidSodium nitrate

The invention discloses a synthetic method for the drug intermediate m-chloroperbenzoic acid. The synthetic method comprises the following steps: adding m-chlorophenylacetamide and a sodium nitrate solution into a reaction vessel, controlling a stirring speed to be 230-260 rpm and a solution temperature to be 10-16 DEG C, adding a methyl n-butyl ether solution and a 1,4-butanediol solution, addingN-bromoacetamide in batches within 20-40 min, and continuing a reaction for 60-90 min; and then adding an aqueous solution and zinc fluoride powder, controlling a stirring speed to be 310-330 rpm, continue the reaction for 3-4 h, carrying out washing with a sodium chloride solution for 30-50 min, then carrying out washing with a 3-heptanol solution for 20-40 min, carrying out recrystallization ina nitroethane solution, and then carrying out dehydration with a dehydrating agent so as to obtain the finished m-chloroperoxybenzoic acid.

Owner:CHENGDU AO KA TE TECH CO LTD

Production device of needle-shaped ferroferric oxide magnetic powder

InactiveCN108238646AReduction of intermediate links in the reactionLow reaction temperatureFerroso-ferric oxidesBiochemical engineeringNeedle Shape

The invention discloses a production device of needle-shaped ferroferric oxide magnetic powder. The production device comprises a reaction kettle (D101), a storage tank (F101), a filter (L101), a scrubber (L102) and a pump (J101), wherein the reaction kettle (D101) is connected with the pump (J101) and the filter (L101) respectively, the filter (L101) is connected with the scrubber (L102), and theinner pot diameter of the reaction kettle (D101) is 1000-1100mm.

Owner:CHENGDU MI ER DUN TECH CO LTD

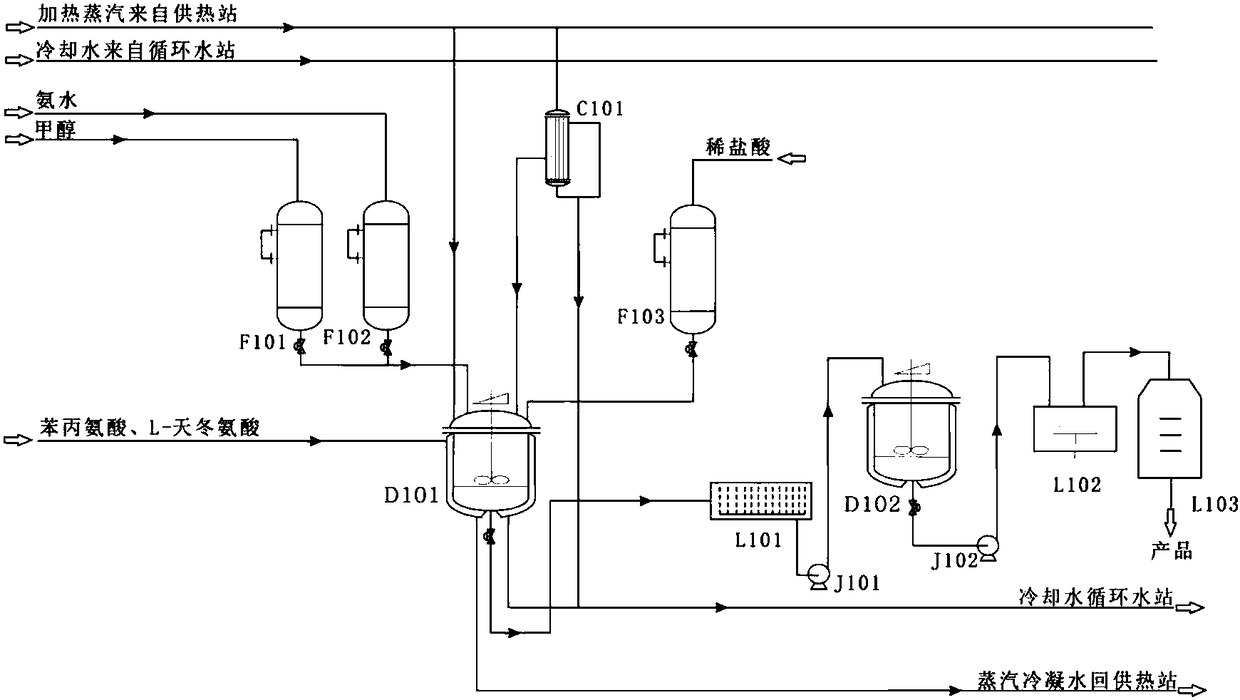

Production apparatus for sweetener cyclohexylsulfamic acid

InactiveCN108238997AReduction of intermediate links in the reactionLow reaction temperatureSulfuric acid amide preparationProcess engineeringFilter press

The invention provides a production apparatus for the sweetener cyclohexylsulfamic acid. The production apparatus mainly comprises a storage tank 1 (F101), a storage tank 2 (F102), a storage tank 3 (F103), a reaction kettle (D101), a condenser (C101), a transfer pump 1 (J101), a transfer pump 2 (J102), a filter press (L101), a crystallization kettle (D102), a centrifuge (L102) and a drier (L103),wherein the storage tank 1 (F101) is connected with the reaction kettle (D101); the storage tank 2 (F102) is connected with the reaction kettle (D101); the storage tank 3 (F103) is connected with thereaction kettle (D101); the condenser (C101) is connected with the reaction kettle (D101); the reaction kettle (D101) is connected with the filter press (L101); the filter press (L101) is connected with the transfer pump 1 (J101); the transfer pump 1 (J101) is connected with the crystallization kettle (D102); the crystallization kettle (D102) is connected with the transfer pump 2 (J102); the transfer pump 2 (J102) is connected with the centrifuge (L102); and the drier (L103) is connected with the centrifuge (L102).

Owner:CHENGDU BO LUO KE TECH CO LTD

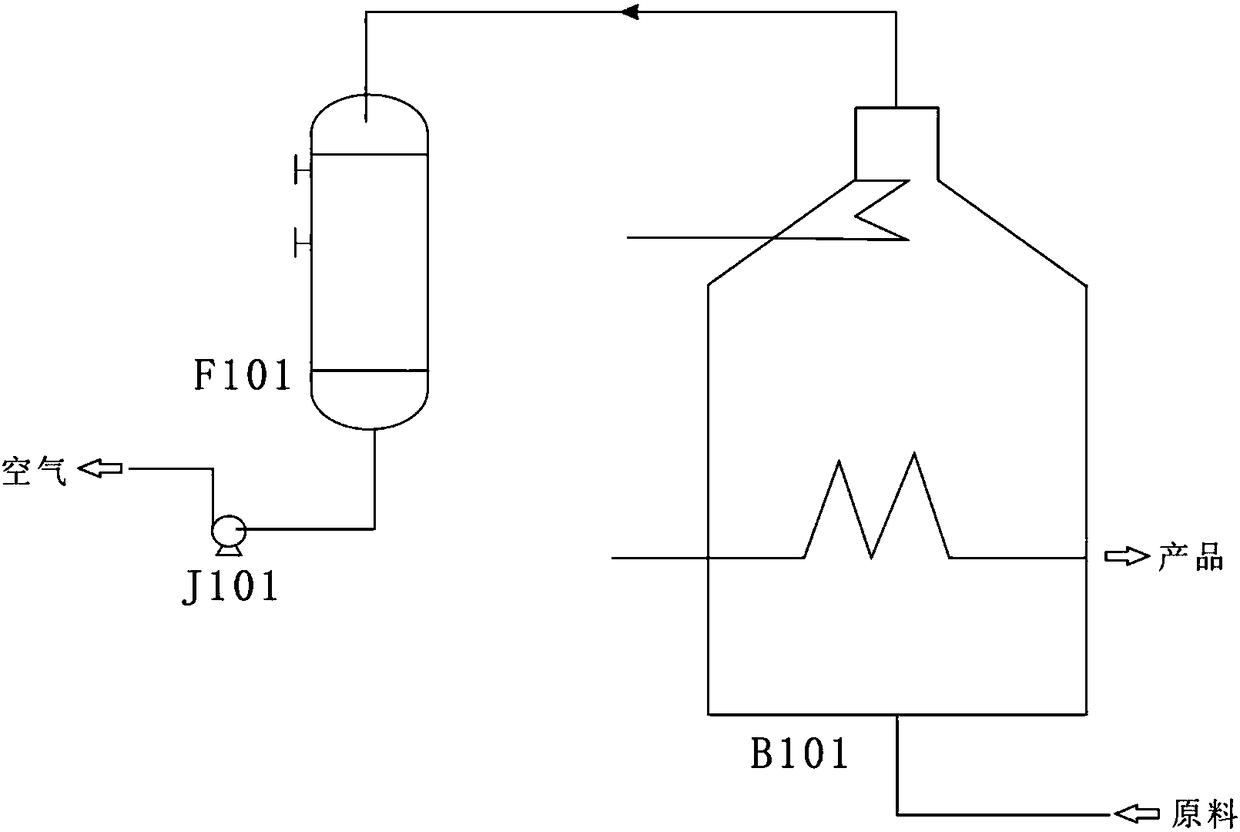

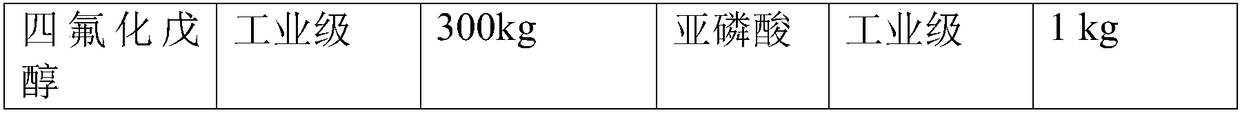

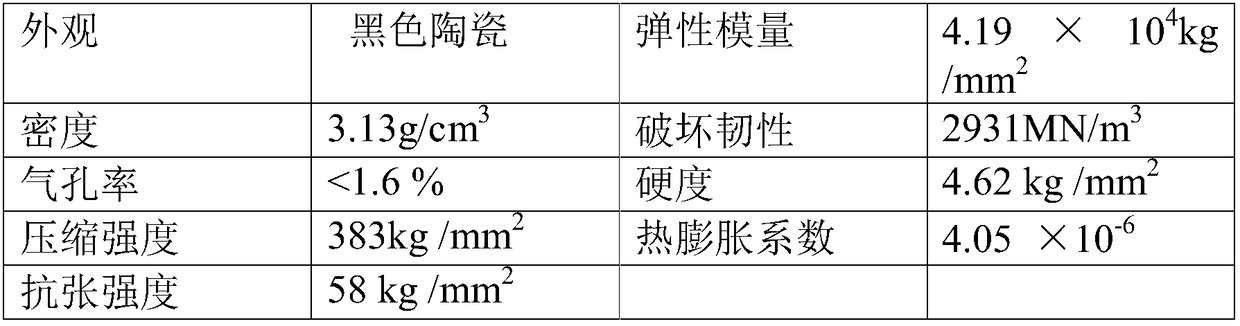

Production device of high-strength material silicon carbide ceramic

The invention discloses a production device of a high-strength material silicon carbide ceramic. The production device mainly comprises a vacuum pump (J101), a buffer tank (F101) and a combustion furnace (B101). The vacuum pump (J101) is connected to the buffer tank (F101) and the buffer tank (F101) is connected to the combustion furnace (B101). The water inlet of the vacuum pump (J101) has the diameter of 170 to 180 mm.

Owner:CHENGDU MENG TE SI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com