Production device of triphenylmethane triisocyanate

A technology of triisocyanate and triphenylmethane, which is applied in the field of production equipment of triphenylmethane triisocyanate, and can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

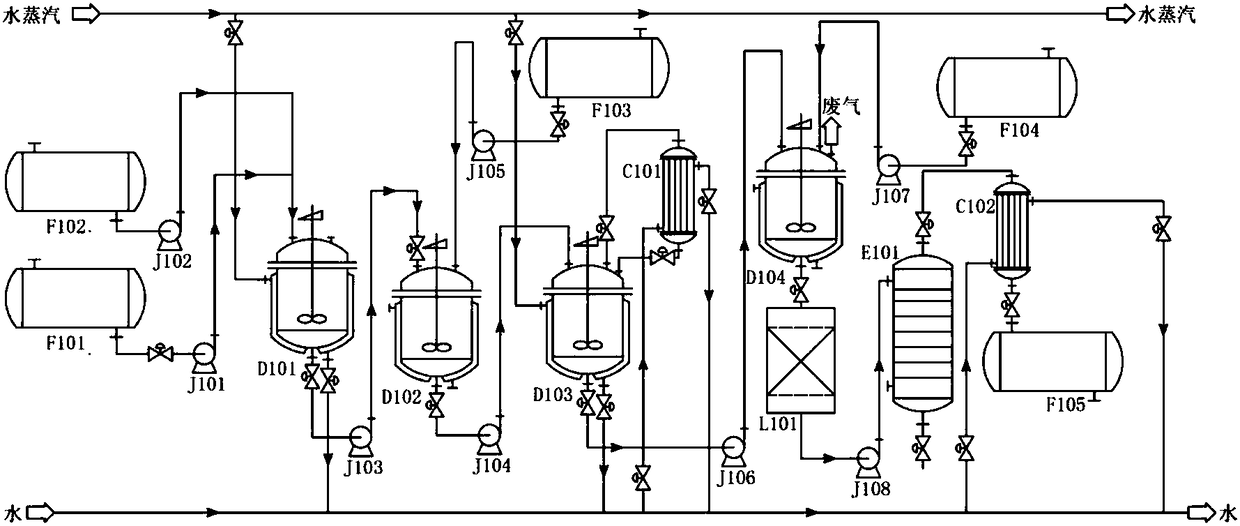

Image

Examples

example 1

[0008] Production raw materials and dosage

[0009] Vice Magenta

industrial grade

300

industrial grade

1000

industrial grade

2700

lye

Industrial grade, 30%

600

[0010] The production device of triphenylmethane triisocyanate mainly includes: low-temperature photochemical kettle (D102), raw material pump (J101), raw material pump (J102), high-temperature photochemical kettle (D103), delivery pump (J103, J104, J106, 108), storage tank (F103), condenser (C101, C102), degassing kettle (D104), vacuum pump (J105, J107), filter (L101), distillation tower (E101), storage tank (F104), finished product Receiving tank (F105), storage tank (F101), storage tank (F102), suspension configuration kettle (D101), wherein, storage tank (F103) is used for storing phosgene, storage tank (F104) is used for storing nitrogen, storage tank The tank (F101) is used to store chlorobenzene, and the storage tank (F102) is used...

example 2

[0015] Production raw materials and dosage

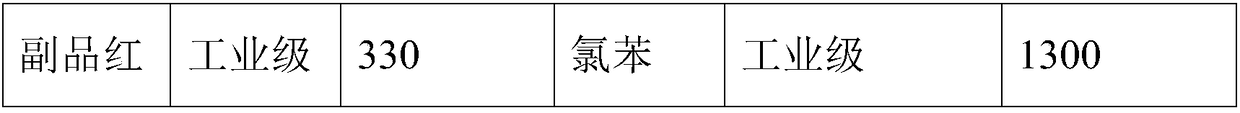

[0016]

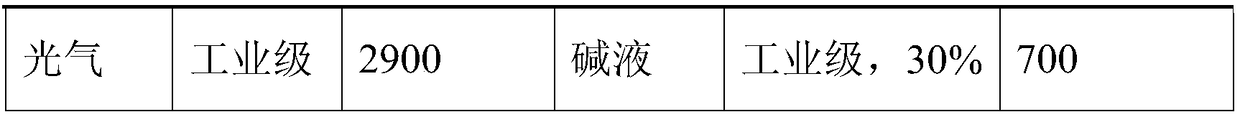

[0017]

[0018] The production device of triphenylmethane triisocyanate mainly includes: low-temperature photochemical kettle (D102), raw material pump (J101), raw material pump (J102), high-temperature photochemical kettle (D103), delivery pump (J103, J104, J106, 108), storage tank (F103), condenser (C101, C102), degassing kettle (D104), vacuum pump (J105, J107), filter (L101), distillation tower (E101), storage tank (F104), finished product Receiving tank (F105), storage tank (F101), storage tank (F102), suspension configuration kettle (D101), wherein, storage tank (F103) is used for storing phosgene, storage tank (F104) is used for storing nitrogen, storage tank The tank (F101) is used to store chlorobenzene, and the storage tank (F102) is used to store vice fuchsin. Among them, the diameter of the water inlet of the raw material pump (J102) is 250mm, and the nominal volume of the storage tank (F103) is 2.3m 3 , C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com