Production device of antistatic agent dodecylbenzyltrimethylammonium chloride

A technique for producing dodecylbenzyltrimethylammonium chloride and production equipment, which is applied in the field of compound synthesis equipment and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

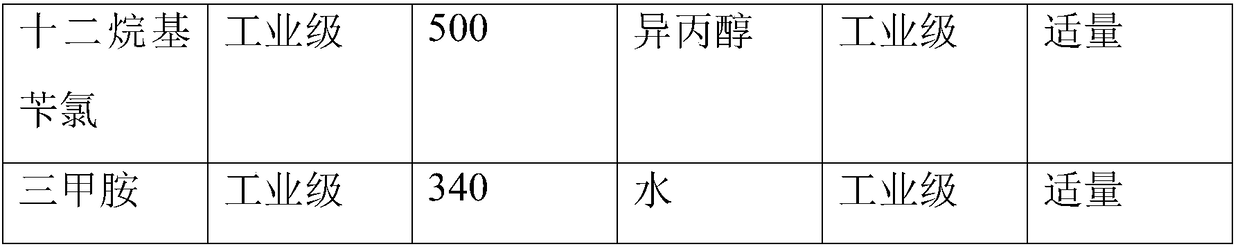

[0008] Production raw materials and dosage

[0009]

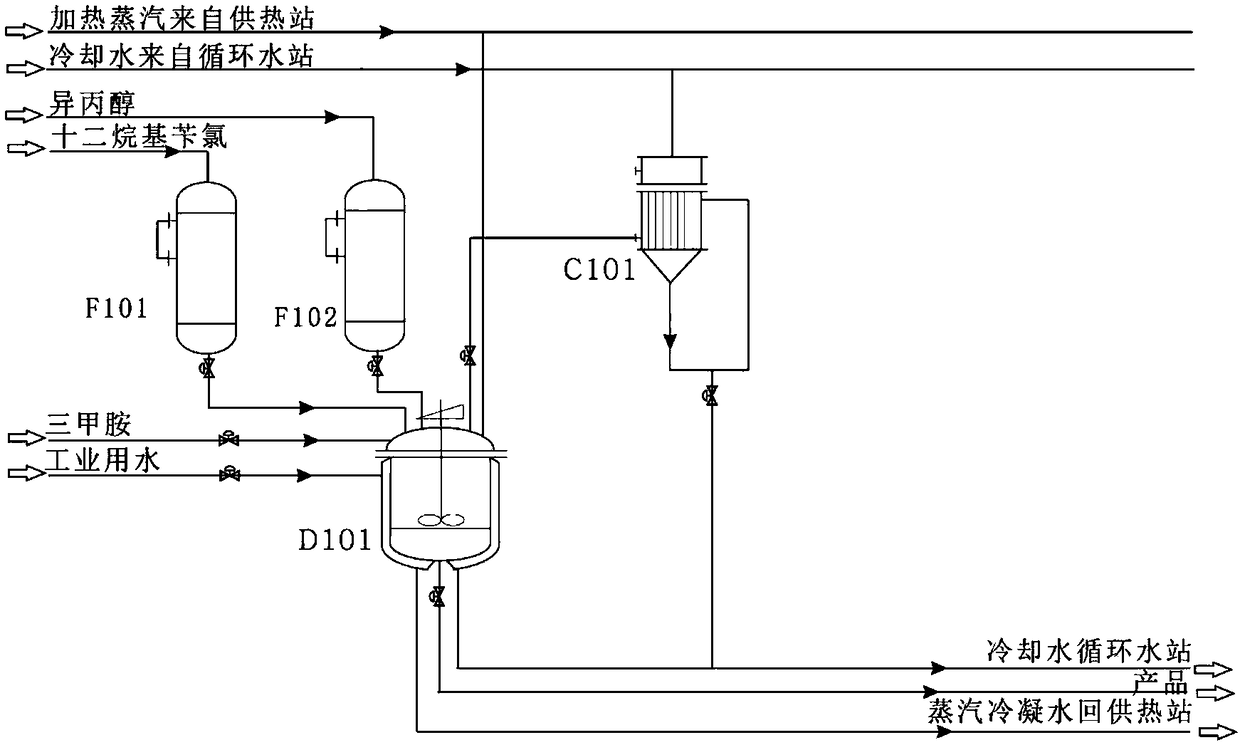

[0010] The production equipment of antistatic agent dodecylbenzyltrimethylammonium chloride mainly includes: reaction kettle (D101), reflux condenser (C101), storage tank 1 (F101), storage tank 2 (F102), production The connection relationship between the various components of the device is: the storage tank 1 (F101) is connected with the reactor (D101), the storage tank 2 (F102) is connected with the reactor (D101), the reflux condenser (C101) is connected with the reactor (D101) are connected, wherein, the diameter of the inner pot of the reaction kettle (D101) is 550mm, the inner diameter of the heat exchange tube of the reflux condenser (C101) is 0.012m, and the thickness of the head of the storage tank 1 (F101) is 8mm.

[0011] The production device of antistatic agent dodecylbenzyltrimethylammonium chloride, the production process is: add dodecylbenzyl chloride and trimethylamine into the reaction kettle D101, heat ...

example 2

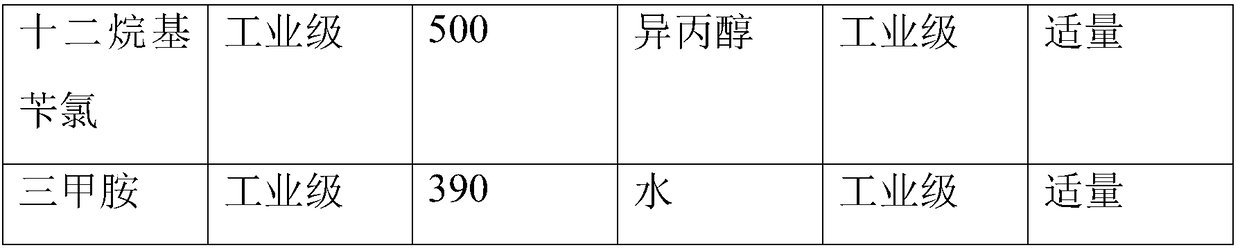

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of antistatic agent dodecylbenzyltrimethylammonium chloride mainly includes: reaction kettle (D101), reflux condenser (C101), storage tank 1 (F101), storage tank 2 (F102), production The connection relationship between the various components of the device is: the storage tank 1 (F101) is connected with the reactor (D101), the storage tank 2 (F102) is connected with the reactor (D101), the reflux condenser (C101) is connected with the reactor (D101) are connected, wherein, the diameter of the inner pot of the reaction kettle (D101) is 600mm, the inner diameter of the heat exchange tube of the reflux condenser (C101) is 0.013m, and the thickness of the head of the storage tank 1 (F101) is 9mm.

[0018] The production device of antistatic agent dodecylbenzyltrimethylammonium chloride, the production process is as follows: add dodecylbenzyl chloride and trimethylamine into the reaction kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com