Production apparatus for acrylonitrile-styrene random copolymer

A technology of random copolymers and production equipment, which is applied in the field of production equipment of acrylonitrile-styrene random copolymers, and can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

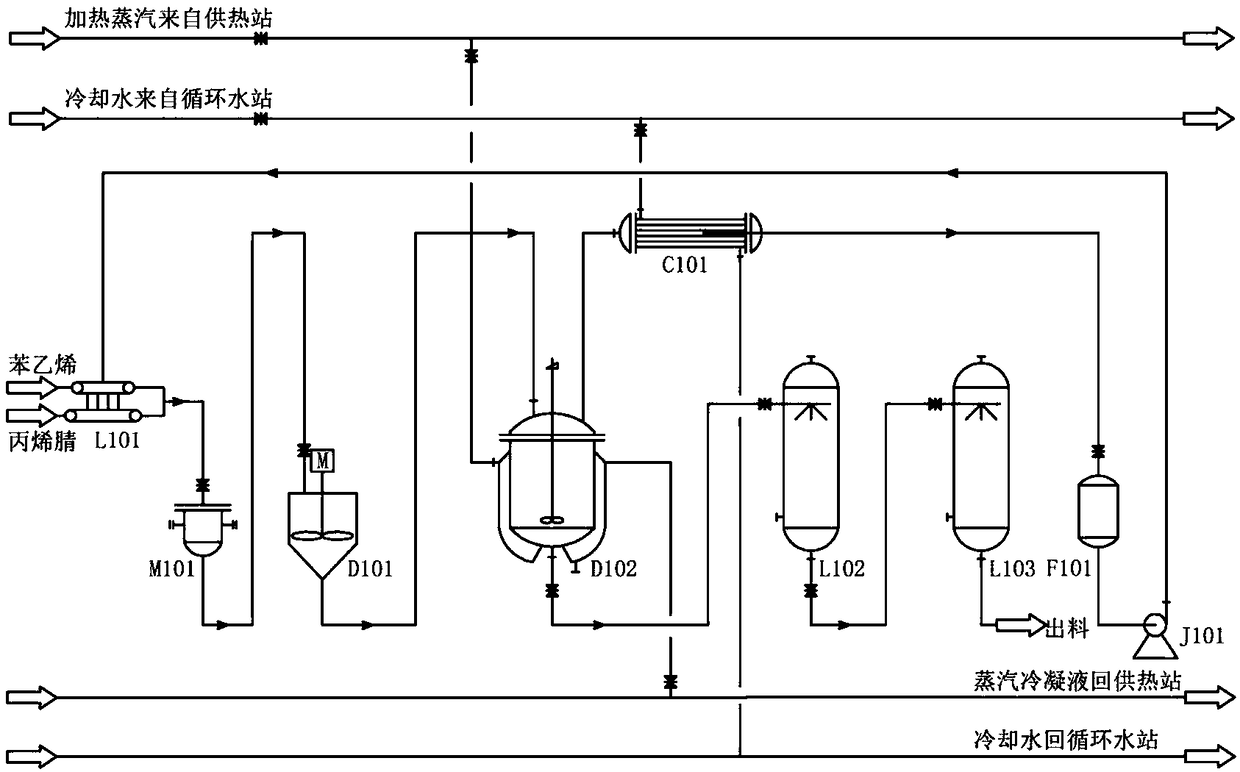

Image

Examples

example 1

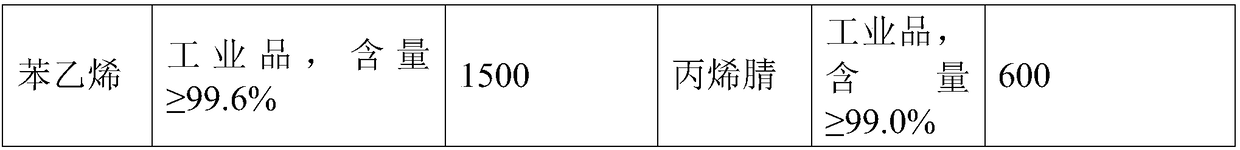

[0008] Production raw materials and dosage

[0009]

[0010] Acrylonitrile-styrene random copolymer production equipment mainly includes: preheater (L101), filter (M101), mixer (D101), polymerization kettle (D102), condenser (C101), devolatilizer (L102), devolatilizer (L103), recovery tank (F101), material pump (J101), wherein, mixer (D101) is connected with filter (M101), polymerization kettle (D102) respectively, devolatilizer ( L102) are respectively connected to the polymerization kettle (D102) and the devolatilizer (L103), wherein the mixer (D101) has a nominal volume of 330L, the condenser (C101) heat exchange tube has a diameter of 0.016m, and the recovery tank (F101) cylinder 1000mm in diameter.

[0011] Acrylonitrile-styrene random copolymer production equipment, the production process is: according to the mass ratio of m (styrene): m (acrylonitrile) = 80: 25, heated to 30 ℃ by the preheater L101, passed through the filter M101 and mixer D101 enter the polymeriza...

example 2

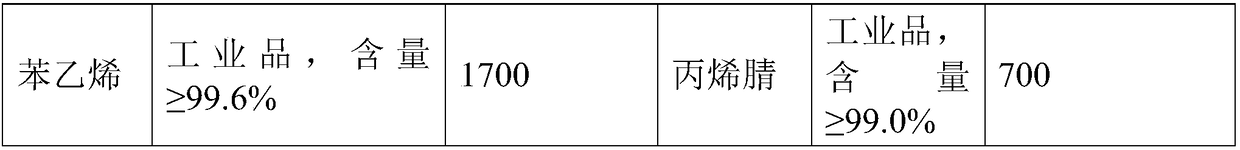

[0015] Production raw materials and dosage

[0016]

[0017] Acrylonitrile-styrene random copolymer production equipment mainly includes: preheater (L101), filter (M101), mixer (D101), polymerization kettle (D102), condenser (C101), devolatilizer (L102), devolatilizer (L103), recovery tank (F101), material pump (J101), wherein, mixer (D101) is connected with filter (M101), polymerization kettle (D102) respectively, devolatilizer ( L102) are respectively connected to the polymerization kettle (D102) and the devolatilizer (L103), wherein the mixer (D101) has a nominal volume of 360L, the condenser (C101) heat exchange tube has a diameter of 0.017m, and the recovery tank (F101) cylinder 1100mm in diameter.

[0018] Acrylonitrile-styrene random copolymer production equipment, the production process is: according to the mass ratio of m (styrene): m (acrylonitrile) = 80: 25, heated to 36 ° C by the preheater L101, passed through the filter M101 and mixer D101 enter the polymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com