Device for producing ethylene-vinyl acetate copolymer

A technology of vinyl acetate copolymerization and production device, applied in the direction of ethylene production, etc., can solve the problems of complex production device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

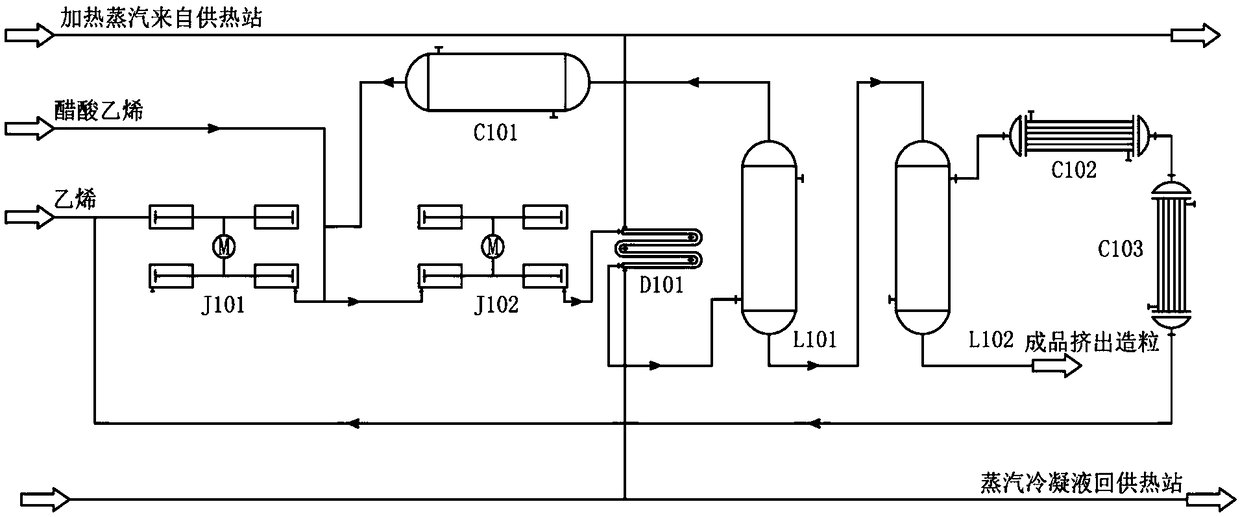

Image

Examples

example 1

[0008] Production raw materials and dosage

[0009] Ethylene

Purity> 99.9%

220

Purity> 99.0%

150

[0010] The production equipment of ethylene-vinyl acetate copolymer mainly includes: primary compressor (J101), secondary compressor (J102), tubular reactor (D101), high pressure circulating cooler (C101), high pressure separator (L101) , Low-pressure separator (L102), water cooler (C102), cooling device (C103), among which the tubular reactor (D101) is connected to the secondary compressor (J102) and high-pressure separator (L101), The separator (L102) is connected to the high-pressure separator (L101) and the water cooler (C102) respectively. Among them, the tubular reactor (D101) has a nominal volume of 320L, and the high-pressure circulating cooler (C101) has an inner diameter of 0.013m. The water cooler (C102) heat exchange tube spacing is 0.022m.

[0011] The production equipment of ethylene-vinyl acetate copolymer, the production process is as follows: inpu...

example 2

[0015] Production raw materials and dosage

[0016] Ethylene

Purity> 99.9%

250

Purity> 99.0%

170

[0017] The production equipment of ethylene-vinyl acetate copolymer mainly includes: primary compressor (J101), secondary compressor (J102), tubular reactor (D101), high pressure circulating cooler (C101), high pressure separator (L101) , Low-pressure separator (L102), water cooler (C102), cooling device (C103), among which the tubular reactor (D101) is connected to the secondary compressor (J102) and high-pressure separator (L101), The separator (L102) is connected to the high-pressure separator (L101) and the water cooler (C102) respectively. Among them, the tubular reactor (D101) has a nominal volume of 350L, and the high-pressure circulating cooler (C101) has an inner diameter of 0.014m. The water cooler (C102) heat exchange tube spacing is 0.024m.

[0018] The production equipment of ethylene-vinyl acetate copolymer. The production process is as follows: inpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com