Device for producing antioxidant 2,6-di-tert-butyl-4-methylphenol

A technology of di-tert-butyl and methyl phenol is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

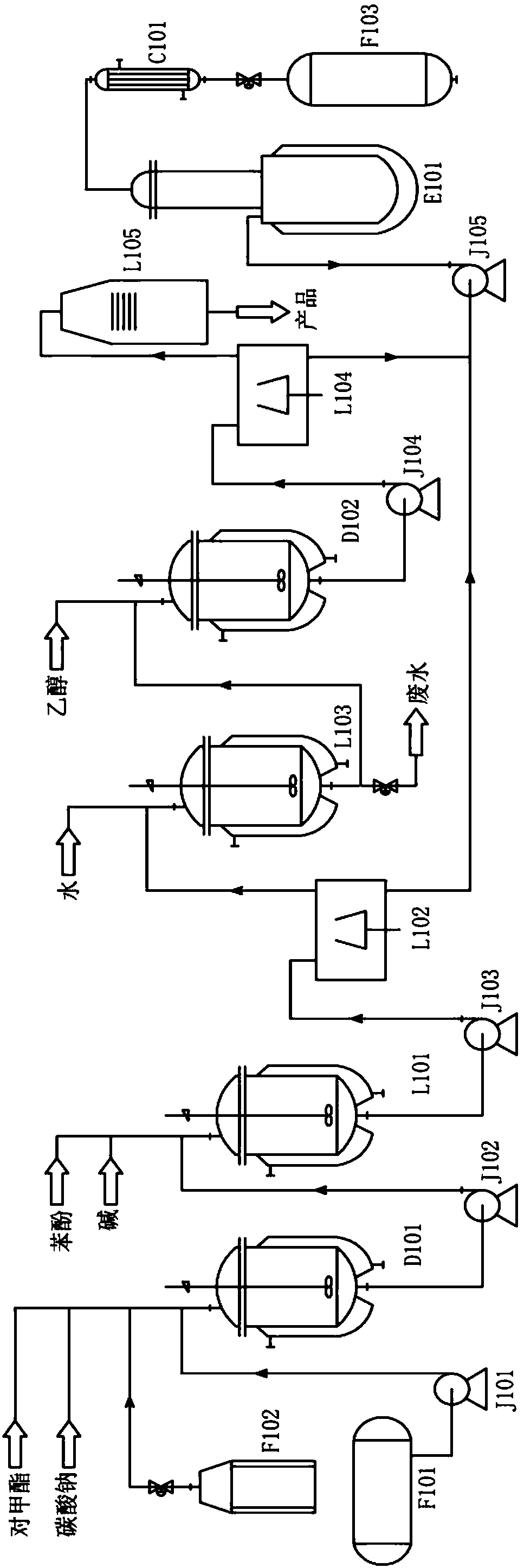

Image

Examples

example 1

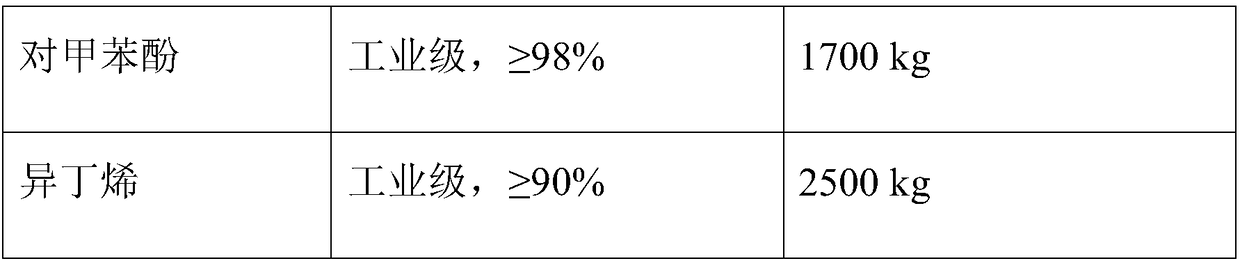

[0008] Production raw materials and dosage

[0009] p-cresol

Industrial grade, ≥98%

1500kg

Industrial grade, ≥90%

2400kg

Industrial grade, 95%

1000kg

concentrated sulfuric acid

Industrial grade, 98%

70kg

industrial grade

Appropriate amount

[0010] Antioxidant 2,6-di-tert-butyl-4-methylphenol production equipment, mainly including: storage tank (F101), bromobutene gasification tank (F102), raw material pump (J101), alkylation neutralization Reactor (D101), delivery pump (J102~J105), alkylation washing tank (L101), centrifuge (L102, L104), melting washing tank (L103), recrystallization reactor (D102), drying oven (L105) , an ethanol distillation tower (E101), a condenser (C101), and an ethanol storage tank (F103), wherein the storage tank (F101) is used to store sulfuric acid, wherein the delivery pump (J103) is connected to the alkylation washing kettle (L101)...

example 2

[0015] Production raw materials and dosage

[0016]

[0017]

[0018] Antioxidant 2,6-di-tert-butyl-4-methylphenol production equipment, mainly including: storage tank (F101), bromobutene gasification tank (F102), raw material pump (J101), alkylation neutralization Reactor (D101), delivery pump (J102~J105), alkylation washing tank (L101), centrifuge (L102, L104), melting washing tank (L103), recrystallization reactor (D102), drying oven (L105) , an ethanol distillation tower (E101), a condenser (C101), and an ethanol storage tank (F103), wherein the storage tank (F101) is used to store sulfuric acid, wherein the delivery pump (J103) is connected to the alkylation washing kettle (L101), The centrifuge (L102) is connected, and the delivery pump (J104) is connected with the recrystallization reactor (D102) and the centrifuge (L104) respectively, wherein the storage tank (F101) has a total volume of 2.5m 3 , The diameter of the impeller of the raw material pump (J101) is 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com