Production method of sodium stearoyl lactylate stabilizer

A technology of calcium sodium stearoyl lactylate and production method, applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve complex problems and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0005] The production method of calcium stearoyl lactate stabilizer, the main steps are: adding lactic acid into the reactor, reducing pressure to 30kPa, dehydrating at 90℃ for 90min, then adding stearic acid and calcium carbonate to the reactor, and then Under the protection of inert gas nitrogen, the temperature is kept at 130℃, and the esterification reaction is carried out for 2h. The material is decolorized and cooled, washed with dichloromethane solution for 80min, recrystallized in ethyl acetate solution, dehydrated by dehydrating agent to obtain the finished product, among which, dichloromethane solution The mass fraction is 30%, and the mass fraction of ethyl acetate solution is 50%.

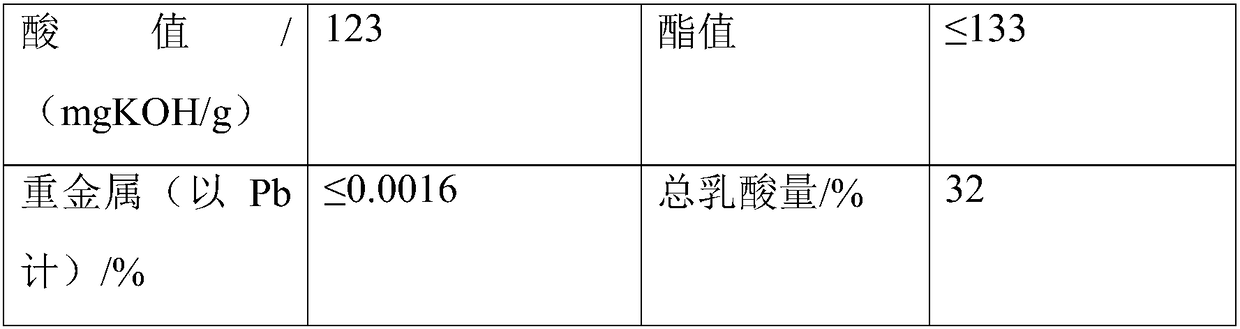

[0006] product quality

[0007]

example 2

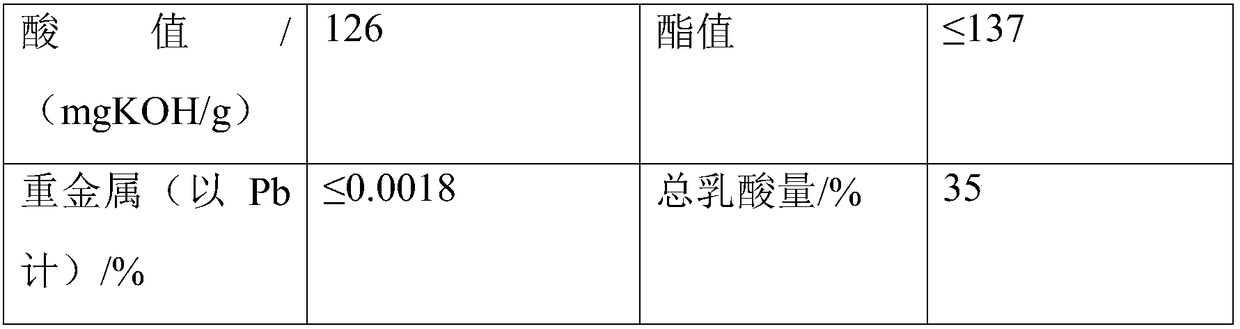

[0009] The production method of calcium sodium stearoyl lactate stabilizer, the main steps are: add lactic acid to the reactor, reduce pressure to 33kPa, dehydration reaction at 96℃ for 120min, then add stearic acid and calcium carbonate to the reactor, and then Under the protection of inert gas nitrogen, the temperature is kept at 140°C, and the esterification reaction is carried out for 3 hours. The material is decolorized and cooled, washed with dichloromethane solution for 100 minutes, recrystallized in ethyl acetate solution, dehydrated by dehydrating agent, and the finished product is obtained. The mass fraction is 34%, and the mass fraction of ethyl acetate solution is 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com