Production device of medical hydrogel polyacrylamide

A technology of hydrogel polyacrylamide and production equipment, which is applied in the field of compound synthesis equipment and can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

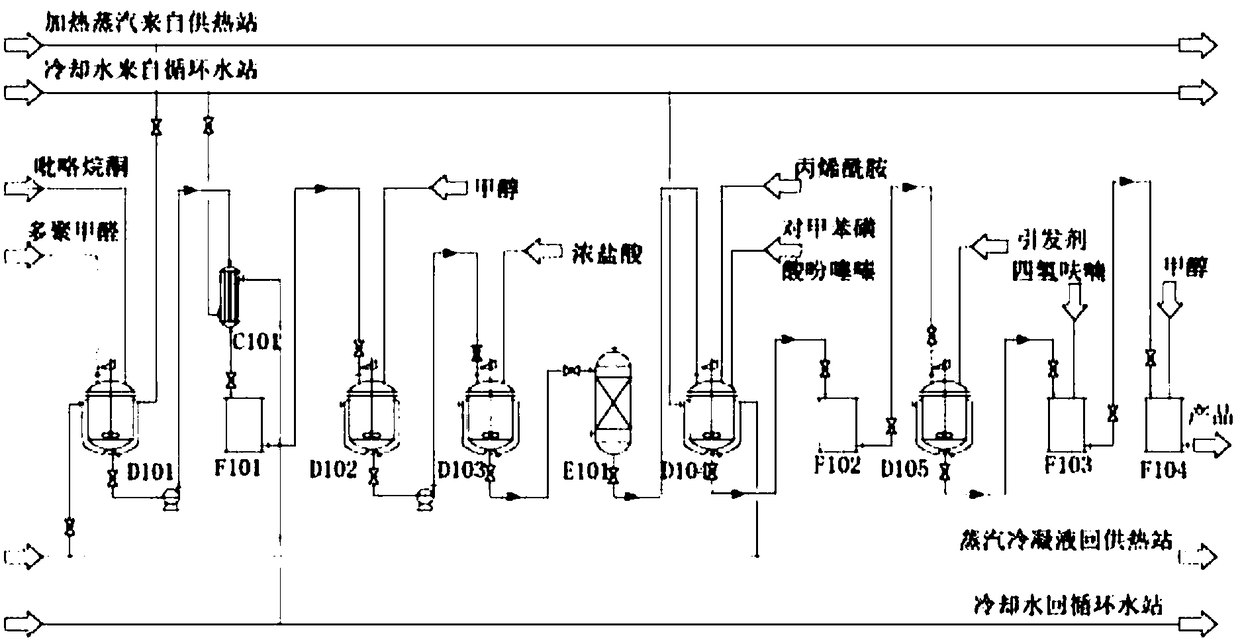

Image

Examples

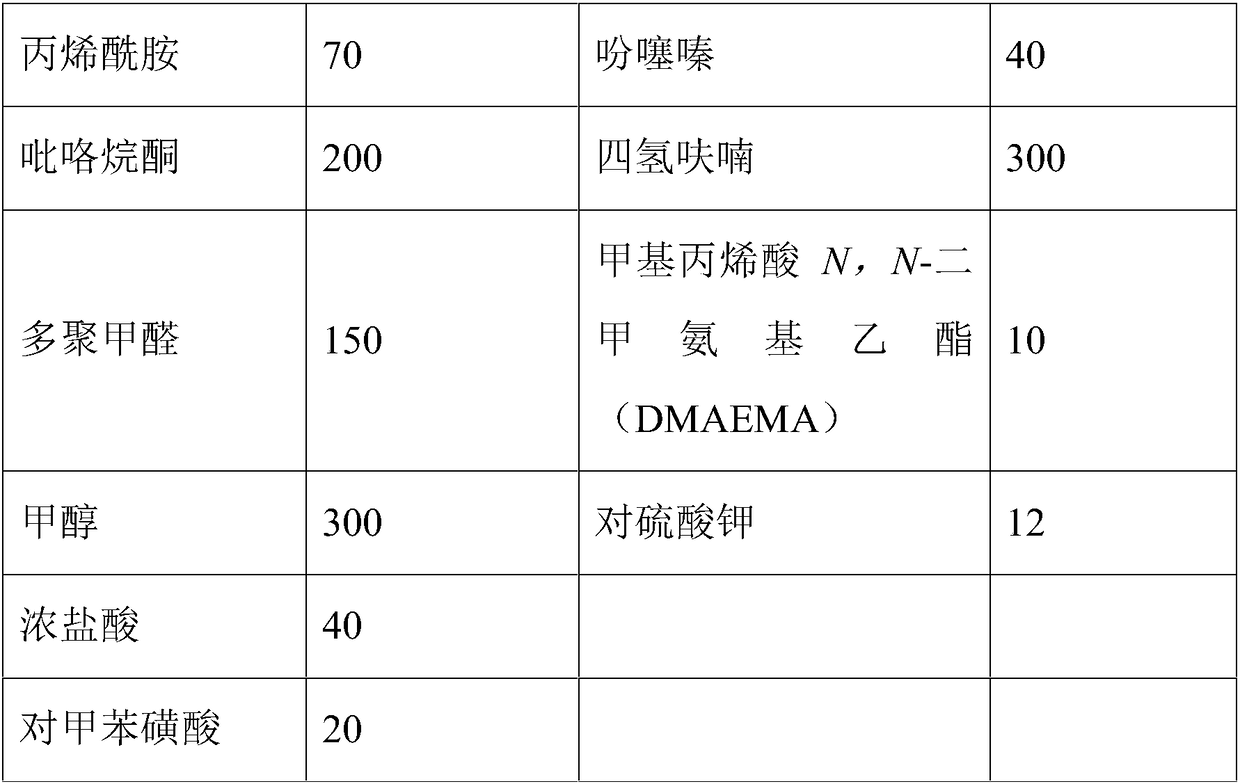

example 1

[0008] Production raw materials and dosage (both industrial grade)

[0009]

[0010] The production equipment of medical hydrogel polyacrylamide mainly includes: polymerization kettle (D101), cooler (C101), crystallization tank (F101), polymerization kettle (D102), neutralization kettle (D103), vacuum distillation tower ( E101), polymerization kettle (D104), crystallization tank (F102), polymerization kettle (D105), precipitation tank (F103), dissolution tank (F104), wherein, vacuum distillation tower (E101) and neutralization tank (D103) , the polymerization kettle (D104) are connected, and the polymerization kettle (D105) is respectively connected with the crystallization tank (F102) and the precipitation tank (F103). Among them, the nominal volume of the polymerization kettle (D101) is 1200L, and the distance between the heat exchange tubes of the cooler (C101) 0.025m, crystallization tank (F101) cylinder diameter 730mm.

[0011] The production device of medical hydroge...

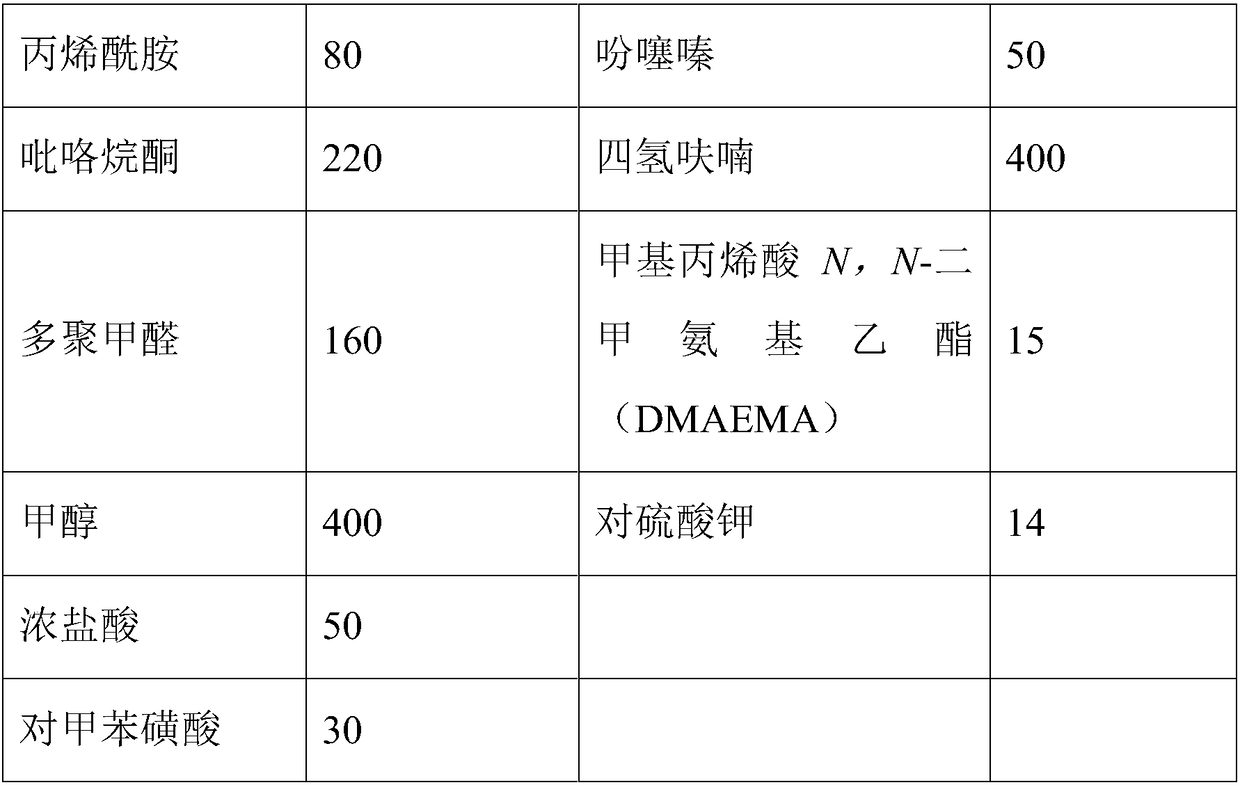

example 2

[0015] Production raw materials and dosage (both industrial grade)

[0016]

[0017] The production equipment of medical hydrogel polyacrylamide mainly includes: polymerization kettle (D101), cooler (C101), crystallization tank (F101), polymerization kettle (D102), neutralization kettle (D103), vacuum distillation tower ( E101), polymerization kettle (D104), crystallization tank (F102), polymerization kettle (D105), precipitation tank (F103), dissolution tank (F104), wherein, vacuum distillation tower (E101) and neutralization tank (D103) , the polymerization kettle (D104) are connected, and the polymerization kettle (D105) is respectively connected with the crystallization tank (F102) and the precipitation tank (F103). Among them, the polymerization kettle (D101) has a nominal volume of 1300L, and the distance between the heat exchange tubes of the cooler (C101) 0.026m, crystallization tank (F101) cylinder diameter 750mm.

[0018] The production device of medical hydrogel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com