Production device of Co-Ti barium ferrite magnetic powder

A technology of barium ferrite and production equipment, which is applied in the field of production equipment of Co-Ti barium ferrite magnetic powder, and can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

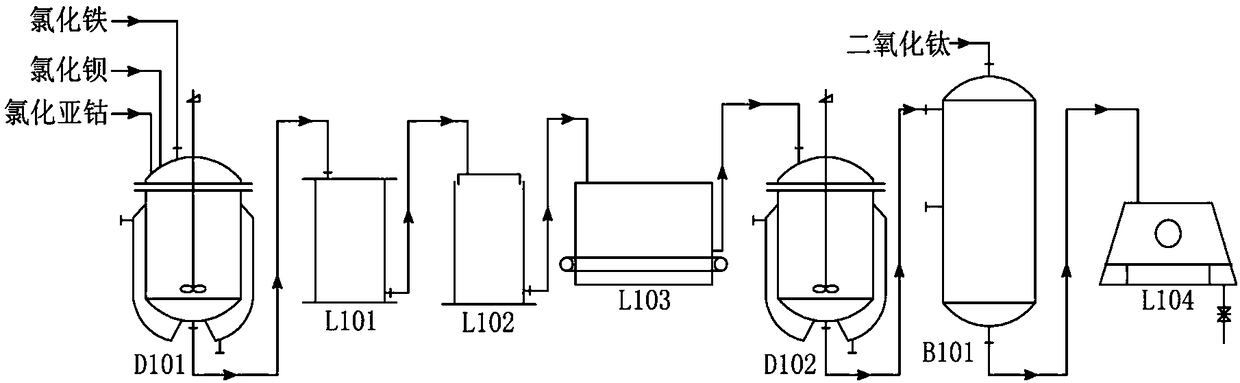

Image

Examples

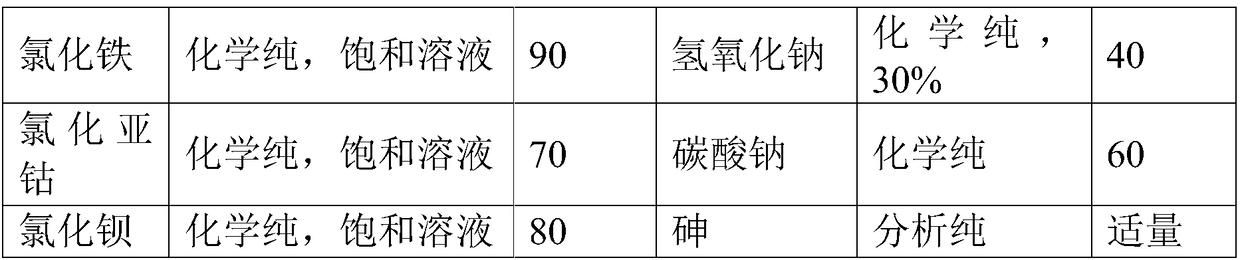

example 1

[0008] Production raw materials and dosage

[0009]

[0010] The production equipment of Co-Ti barium ferrite magnetic powder mainly includes: mixing kettle (D101), mixing kettle (D102), filter (L101), scrubber (L102), dryer (L103), ball mill (L104), A sintering furnace (B101), wherein the filter (L101) is connected to the mixing kettle (D101) and the scrubber (L102) respectively, and the mixing kettle (D102) is connected to the dryer (L103) and the sintering furnace (B101) respectively, Among them, the nominal volume of the mixing kettle (D101) is 1300L, the diameter of the inner pot of the mixing kettle (D101) is 600mm, and the diameter of the outer pot of the mixing kettle (D102) is 1200mm.

[0011] Co-Ti barium ferrite magnetic powder production equipment, the production process is: mix the chloride salt solution of Fe, Ba, Co in a certain proportion in the mixing kettle D101, and then add NaOH, Na 2 CO 3 Alkaline solution makes it co-precipitate. The precipitate is ...

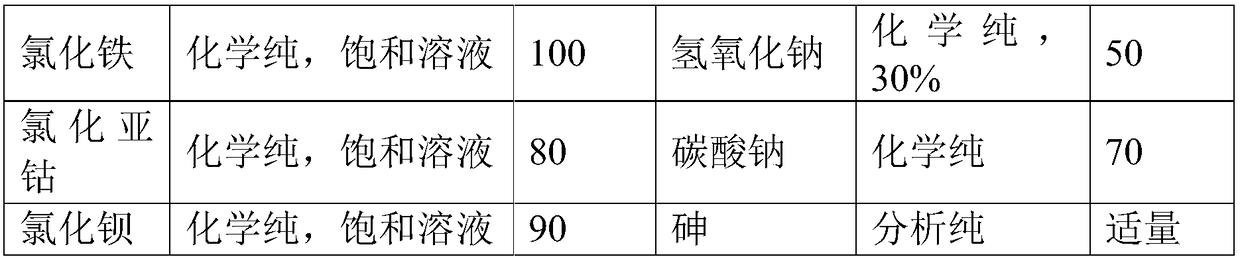

example 2

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of Co-Ti barium ferrite magnetic powder mainly includes: mixing kettle (D101), mixing kettle (D102), filter (L101), scrubber (L102), dryer (L103), ball mill (L104), A sintering furnace (B101), wherein the filter (L101) is connected to the mixing kettle (D101) and the scrubber (L102) respectively, and the mixing kettle (D102) is connected to the dryer (L103) and the sintering furnace (B101) respectively, Among them, the nominal volume of the mixing kettle (D101) is 1500L, the diameter of the inner pot of the mixing kettle (D101) is 670mm, and the diameter of the outer pot of the mixing kettle (D102) is 1300mm.

[0018] Co-Ti barium ferrite magnetic powder production equipment, the production process is: mix the chloride salt solution of Fe, Ba, Co in a certain proportion in the mixing kettle D101, and then add NaOH, Na 2 CO 3 Alkaline solution makes it co-precipitate. The precipitate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com