Device for producing cyclized polyisoprene resist

A technology for polyisoprene and production equipment, which is applied in the field of production equipment for cyclized polyisoprene resists, and can solve complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

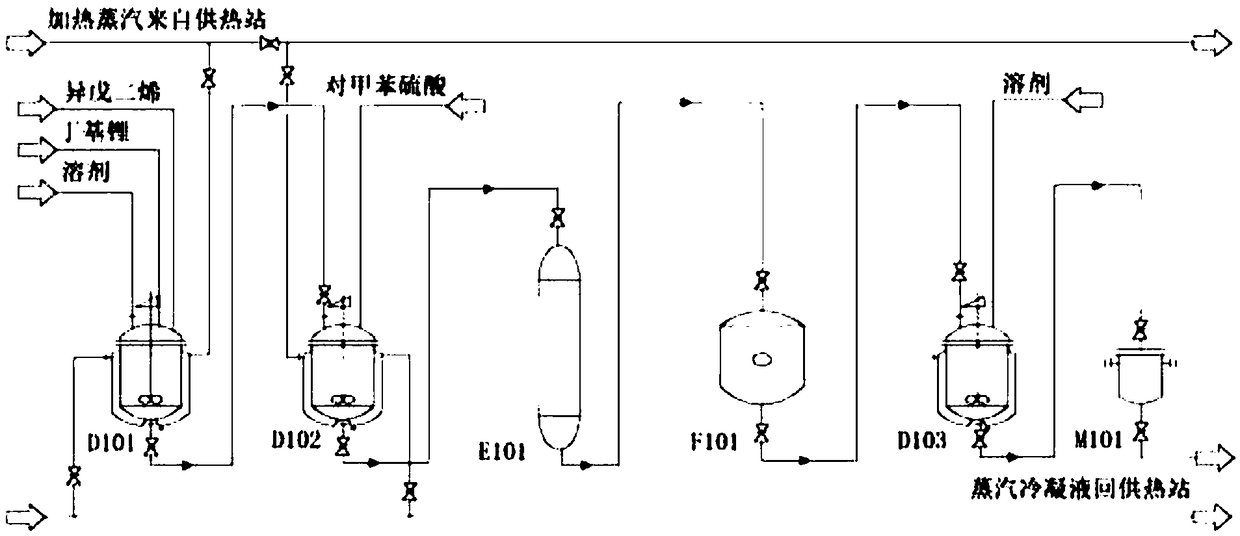

Image

Examples

example 1

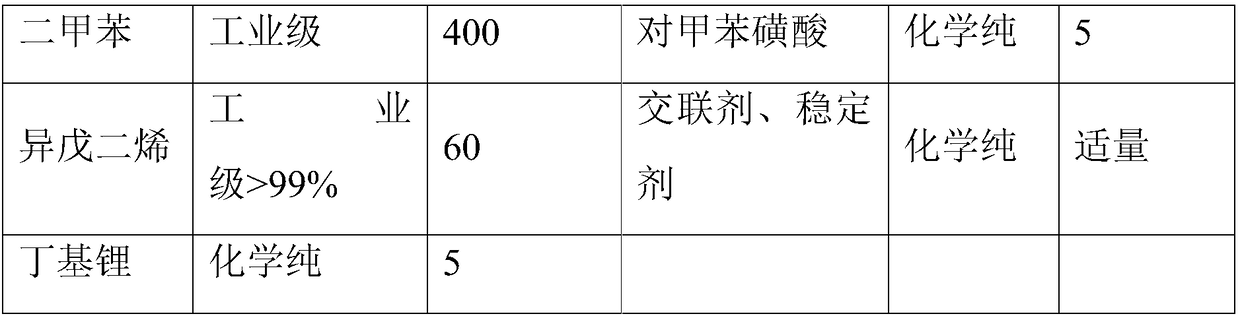

[0008] Production raw materials and dosage

[0009]

[0010] The production equipment of cyclized polyisoprene resist mainly includes: polymerization vessel (D101), cyclization vessel (D102), washing tower (E101), concentrator (F101), glue mixing vessel (D103), filtration (M101), in which the washing tower (E101) is connected to the cyclization reactor (D102) and the concentrator (F101), and the glue mixing reactor (D103) is connected to the concentrator (F101) and the filter (M101). Among them, the nominal volume of the polymerization reactor (D101) is 630L, the jacket capacity of the cyclization reactor (D102) is 570L, and the outer pot diameter of the glue reactor (D103) is 1200mm.

[0011] The production device of the cyclized polyisoprene resist, the production process is: adding high-purity isoprene into the polymerizer D101, then adding the dehydrated and refined xylene, and dissolving under stirring. Add the initiator butyl lithium, control the temperature to 70°C, and car...

example 2

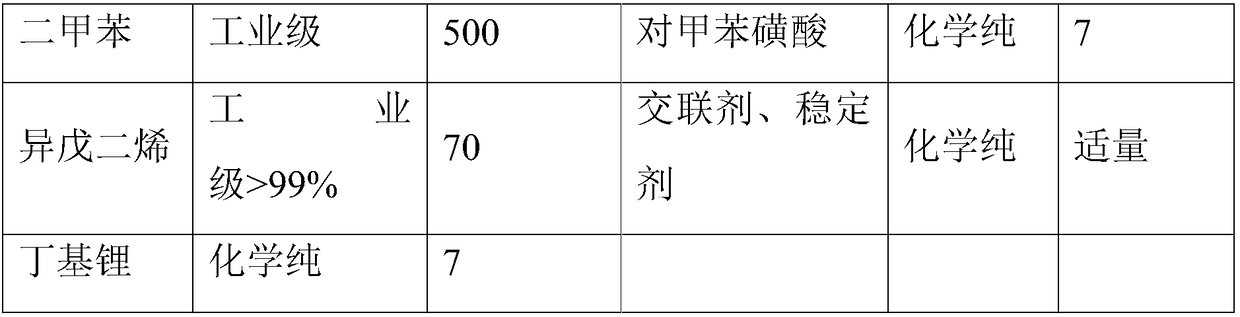

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of cyclized polyisoprene resist mainly includes: polymerization vessel (D101), cyclization vessel (D102), washing tower (E101), concentrator (F101), glue mixing vessel (D103), filtration (M101), in which the washing tower (E101) is connected to the cyclization reactor (D102) and the concentrator (F101), and the glue mixing reactor (D103) is connected to the concentrator (F101) and the filter (M101). Among them, the nominal volume of the polymerization reactor (D101) is 660L, the jacket capacity of the cyclization reactor (D102) is 590L, and the outer pot diameter of the glue reactor (D103) is 1300mm.

[0018] The production device of the cyclized polyisoprene resist, the production process is: adding high-purity isoprene into the polymerizer D101, then adding the dehydrated and refined xylene, and dissolving under stirring. Add the initiator butyl lithium, control the temperature to 76°C, and car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com