Production device for heat-resistant resin antistatic agent namely secondary alkyl sodium sulfonate

A technology of sodium secondary alkyl sulfonate and antistatic agent, applied in the field of compound synthesis devices, can solve the problems of complex production devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

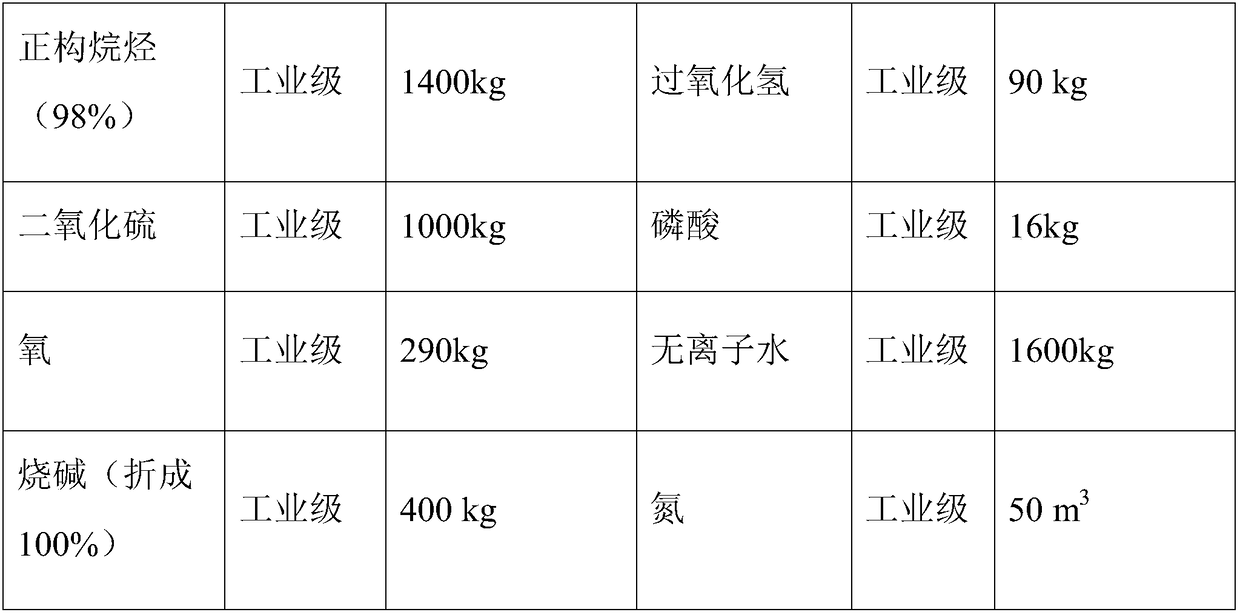

[0008] Production raw materials and dosage

[0009]

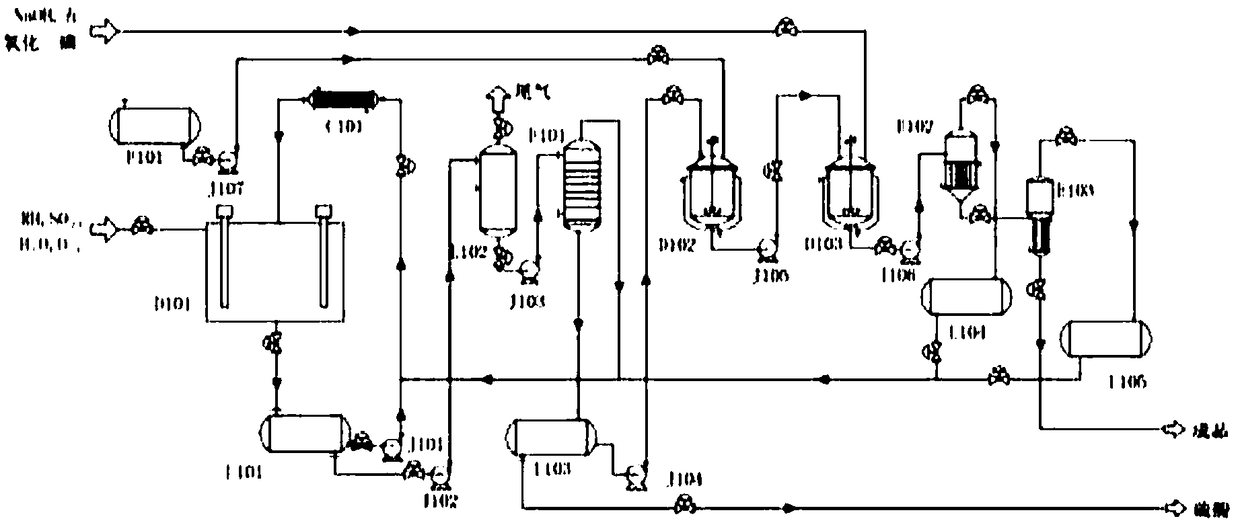

[0010] The production equipment of heat-resistant resin antistatic agent sodium secondary alkyl sulfonate mainly includes: storage tank (F101), photochemical reactor (D101), cooler (C101), gas-liquid separator (L102), separation tank ( L101, L103~L105), reflux pump (J101), falling film evaporation tower (E101), bleaching tank (D102), neutralization tank (D103), delivery pump (J102~J107), evaporator (E102), stripping Tower (E103), wherein the storage tank (F101) is used to store hydrogen peroxide, wherein the delivery pump (J107) is connected to the storage tank (F101) and the bleach tank (D102) respectively, and the delivery pump (J102) is connected to the separation tank ( L101) and the gas-liquid separator (L102) are connected, where the wall thickness of the storage tank (F101) is 7mm, the distance between the heat exchange tubes of the cooler (C101) is 0.026m, and the diameter of the water inlet of the delivery pump ...

example 2

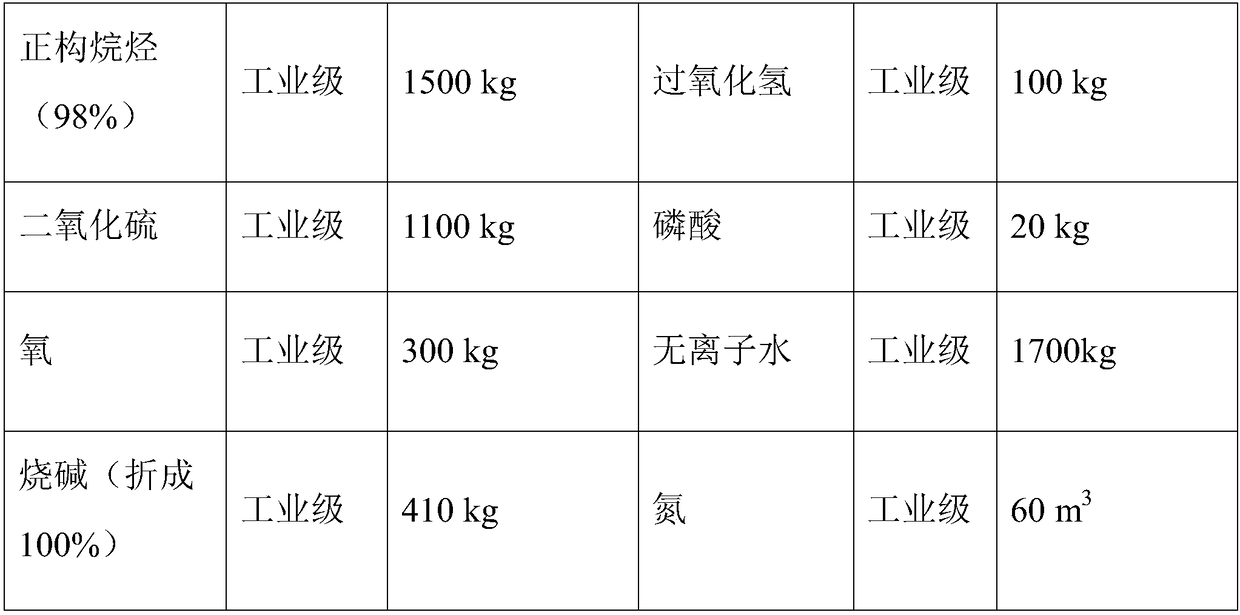

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of heat-resistant resin antistatic agent sodium secondary alkyl sulfonate mainly includes: storage tank (F101), photochemical reactor (D101), cooler (C101), gas-liquid separator (L102), separation tank ( L101, L103~L105), reflux pump (J101), falling film evaporation tower (E101), bleaching tank (D102), neutralization tank (D103), delivery pump (J102~J107), evaporator (E102), stripping Tower (E103), wherein the storage tank (F101) is used to store hydrogen peroxide, wherein the delivery pump (J107) is connected to the storage tank (F101) and the bleach tank (D102) respectively, and the delivery pump (J102) is connected to the separation tank ( L101) and the gas-liquid separator (L102) are connected, where the wall thickness of the storage tank (F101) is 9mm, the heat exchange tube spacing of the cooler (C101) is 0.029m, and the water inlet diameter of the delivery pump (J102) is 226mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com