Production device of viscose fiber colorant chrysophenine GX

A technology for viscose fiber and production equipment, which is applied in the fields of disazo dyes, sulfonate preparation, organic chemistry, etc., and can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

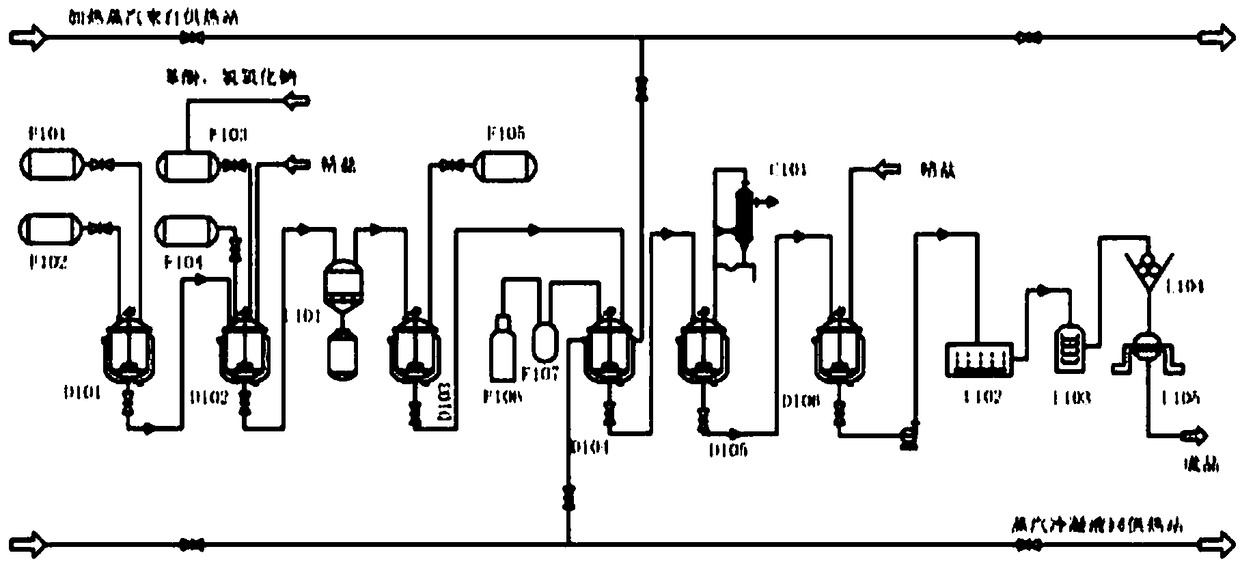

Image

Examples

example 1

[0008] Production raw materials and dosage

[0009] DSD acid

industrial grade

1000

31%

140

industrial grade

500

industrial grade

100

95%

1200

Yuan Mingfen

industrial grade

140

98%

2200

industrial grade

480

industrial grade

340

Refined salt

industrial grade

4800

industrial grade

220

[0010] The production equipment of viscose dyeing agent direct frozen yellow GX mainly includes: storage tank (F101), storage tank (F102), dissolving tank (F103), storage tank (F104), storage tank (F105), condenser (C101 ), pulverizer (L104), filter press (L102), dryer (L103), blending machine (L105), diazotization kettle (D101), coupling kettle (D102), suction filter (L101), beating kettle (D103), ethyl chloride cylinder (F106), buffer...

example 2

[0015] Production raw materials and dosage

[0016] DSD acid

industrial grade

1100

31%

150

industrial grade

550

industrial grade

110

95%

1300

Yuan Mingfen

industrial grade

150

98%

2300

industrial grade

490

industrial grade

350

Refined salt

industrial grade

4900

industrial grade

230

[0017] The production equipment of viscose dyeing agent direct frozen yellow GX mainly includes: storage tank (F101), storage tank (F102), dissolving tank (F103), storage tank (F104), storage tank (F105), condenser (C101 ), pulverizer (L104), filter press (L102), dryer (L103), blending machine (L105), diazotization kettle (D101), coupling kettle (D102), suction filter (L101), beating kettle (D103), ethyl chloride cylinder (F106), buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com