Method for producing oil antioxidant namely tert-butyl hydroquinone

A technology of tert-butylhydroquinone and antioxidant, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., capable of solving complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0005] The production method of oil antioxidant tert-butyl hydroquinone, the main steps are: add hydroquinone, concentrated sulfuric acid and toluene to a reaction kettle, heat up to 80°C, slowly add equimolar tert-butyl alcohol, Phenol, reacted for 2 hours, separated the hot toluene layer, then distilled off the toluene with steam, hot filtered the water-containing residue, washed with p-xylene solution for 30 minutes, recrystallized in N,N-dimethylformamide solution, The obtained product, wherein, the mass fraction of p-xylene solution is 60%, and the mass fraction of N,N-dimethylformamide solution is 70%.

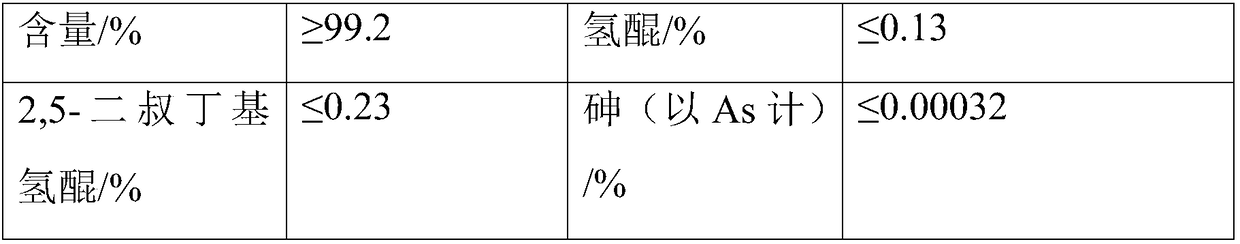

[0006] product quality

[0007]

example 2

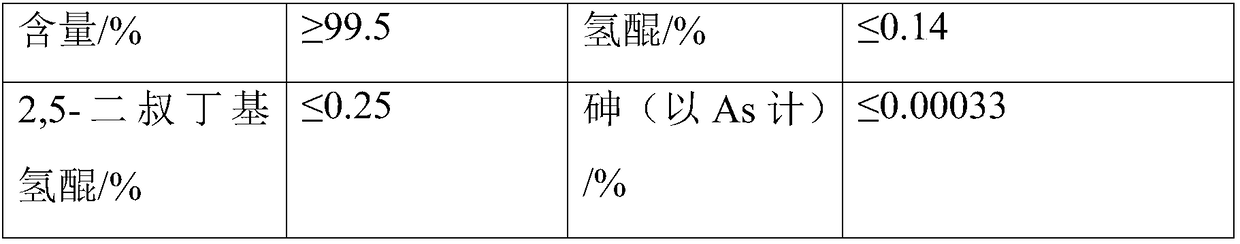

[0009] The production method of oil antioxidant tert-butyl hydroquinone, the main steps are: adding hydroquinone, concentrated sulfuric acid and toluene to a reaction kettle, heating up to 84°C, slowly adding equimolar tert-butyl alcohol, Phenol, reacted for 3 hours, separated the hot toluene layer, then distilled off the toluene with steam, hot filtered the water-containing residue, washed with p-xylene solution for 50 minutes, recrystallized in N,N-dimethylformamide solution, The obtained product, wherein, the mass fraction of p-xylene solution is 65%, and the mass fraction of N,N-dimethylformamide solution is 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com