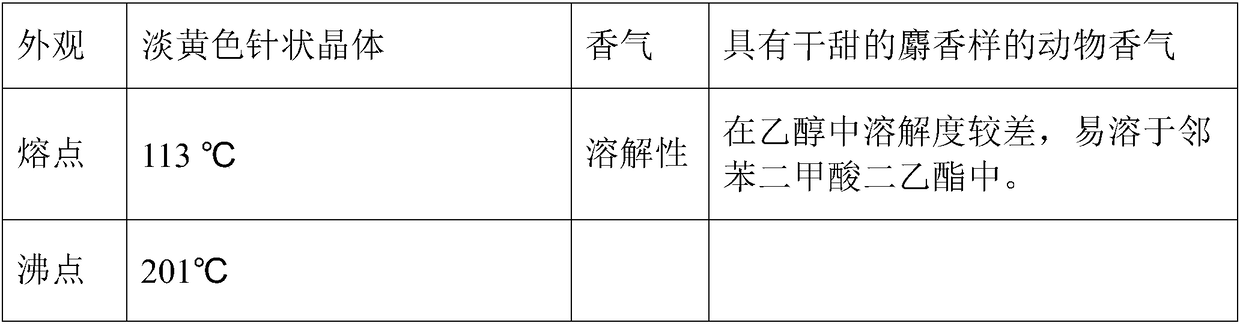

Production device for 2,4,6-trinitro-3,3-dimethyl-5-tert-butylbenzene

A technology for tert-butylbenzene and production equipment, which is applied in the preparation of nitro compounds, hydrocarbons, hydrocarbons, etc., can solve the problems of very good use effect, complexity, and increased epidermal absorption of drugs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

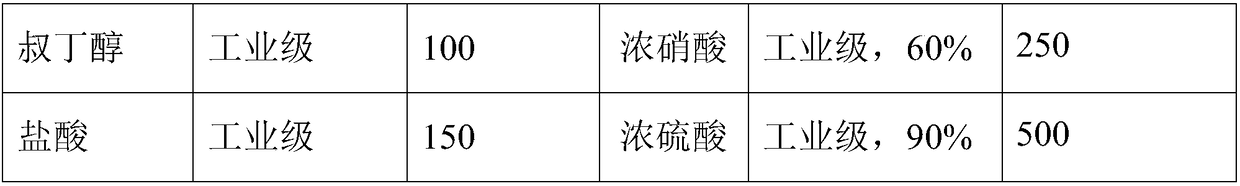

[0008] Production raw materials and dosage

[0009] tert-butanol

industrial grade

80

concentrated nitric acid

Industrial grade, 60%

200

industrial grade

120

concentrated sulfuric acid

Industrial grade, 90%

400

m-xylene

industrial grade

150

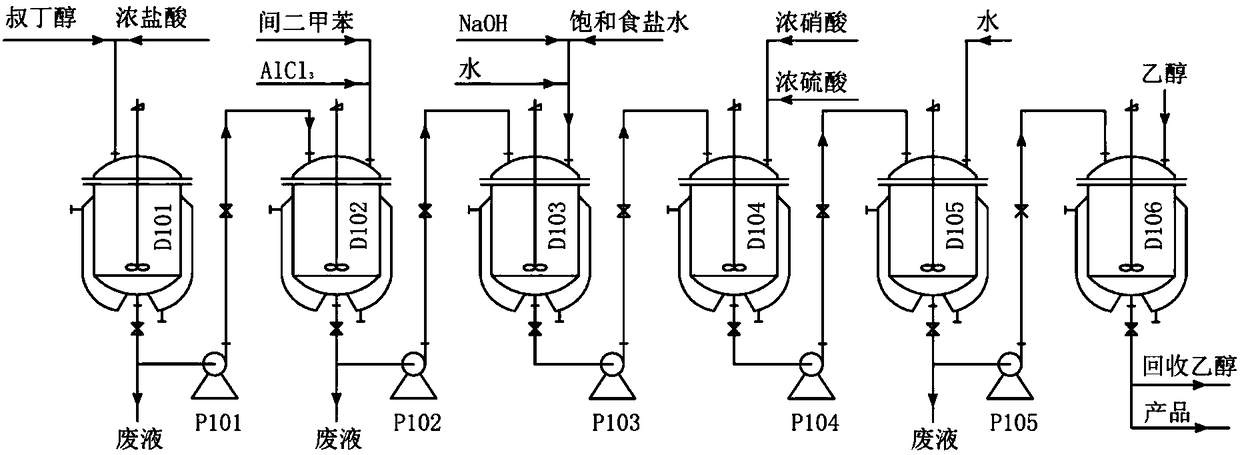

[0010] The production equipment of 2,4,6-trinitro-3,3-dimethyl-5-tert-butylbenzene mainly includes: chlorination tank (D101), condensation tank (D102), neutralization washing tank (D103 ), delivery pump (P101~P105), nitrification tank (D104), washing tank (D105), crystallization tank (D106), among which, delivery pump (P101) is connected with chlorination tank (D101) and condensation tank (D102) respectively Connection, the delivery pump (P104) is connected with the nitrification tank (D104) and the water washing tank (D105) respectively, among which, the impeller diameter of the delivery pump (P103) is 107-112mm, the jacket capacity of the...

example 2

[0015] Production raw materials and dosage

[0016]

[0017]

[0018] The production equipment of 2,4,6-trinitro-3,3-dimethyl-5-tert-butylbenzene mainly includes: chlorination tank (D101), condensation tank (D102), neutralization washing tank (D103 ), delivery pump (P101~P105), nitrification tank (D104), washing tank (D105), crystallization tank (D106), among which, delivery pump (P101) is connected with chlorination tank (D101) and condensation tank (D102) respectively Connection, the delivery pump (P104) is connected with the nitrification tank (D104) and the water washing tank (D105) respectively, among which, the impeller diameter of the delivery pump (P103) is 112mm, the jacket capacity of the washing tank (D105) is 280L, and the crystallization tank (D106) The diameter of the pot is 650mm.

[0019] 2,4,6-trinitro-3,3-dimethyl-5-tert-butylbenzene production device, the production process is: add tert-butanol and excess hydrochloric acid into the chlorination tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com