Production device of medicine intermediate high-purity toluene

A technology for production equipment and toluene, which is applied in the field of production equipment for high-purity toluene, a pharmaceutical intermediate, and can solve problems such as complex production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

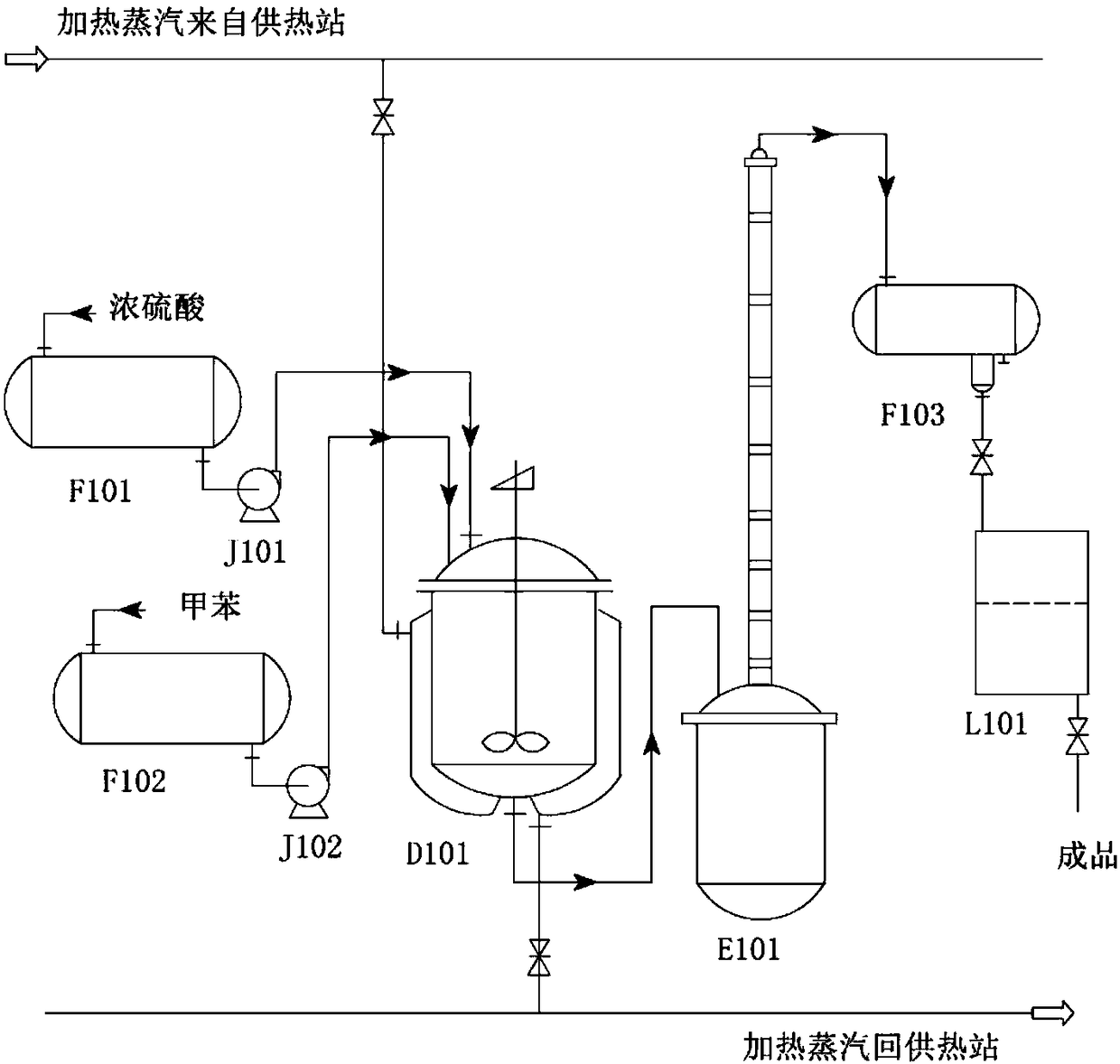

Image

Examples

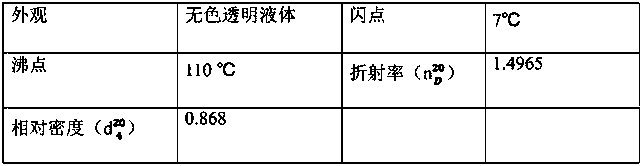

example 1

[0008] Production raw materials and dosage

[0009] toluene

industrial grade

120

water

50

Industrial grade, 40%

60

[0010] The production equipment of high-purity toluene, a pharmaceutical intermediate, mainly includes: storage tank (F102), storage tank (F103), stirred tank (D101), distillation tower (E101), storage tank (F101), pump (J101), pump (J102 ), ultra-clean filter (L101), wherein, storage tank (F102) is used for storing toluene, storage tank (F103) is used for storing crude product, and storage tank (F101) is used for storing sulfuric acid, and wherein, pump (J102) and The storage tank (F102) and the stirring tank (D101) are connected, and the storage tank (F103) is respectively connected with the distillation tower (E101) and the ultra-clean filter (L101). The kettle (D101) jacket capacity is 230 L, and the pump (J102) outlet diameter is 170mm.

[0011] The production proc...

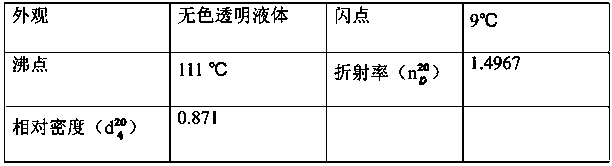

example 2

[0015] Production raw materials and dosage

[0016] toluene

industrial grade

140

water

70

sulfuric acid

Industrial grade, 40%

80

[0017] The production equipment of high-purity toluene, a pharmaceutical intermediate, mainly includes: storage tank (F102), storage tank (F103), stirred tank (D101), distillation tower (E101), storage tank (F101), pump (J101), pump (J102 ), ultra-clean filter (L101), wherein, storage tank (F102) is used for storing toluene, storage tank (F103) is used for storing crude product, and storage tank (F101) is used for storing sulfuric acid, and wherein, pump (J102) and The storage tank (F102) and the stirred tank (D101) are connected, and the storage tank (F103) is respectively connected with the distillation tower (E101) and the ultra-clean filter (L101). The jacket capacity of kettle (D101) is 260 L, and the outlet diameter of pump (J102) is 190mm.

[0018] The production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Barrel diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com