Production device of diisopropyl-S-benzyl sulfide phosphate

A technology of benzyl phosphorothioate and diisopropyl, which is applied in the field of production equipment of diisopropyl-S-benzyl phosphorothioate, and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

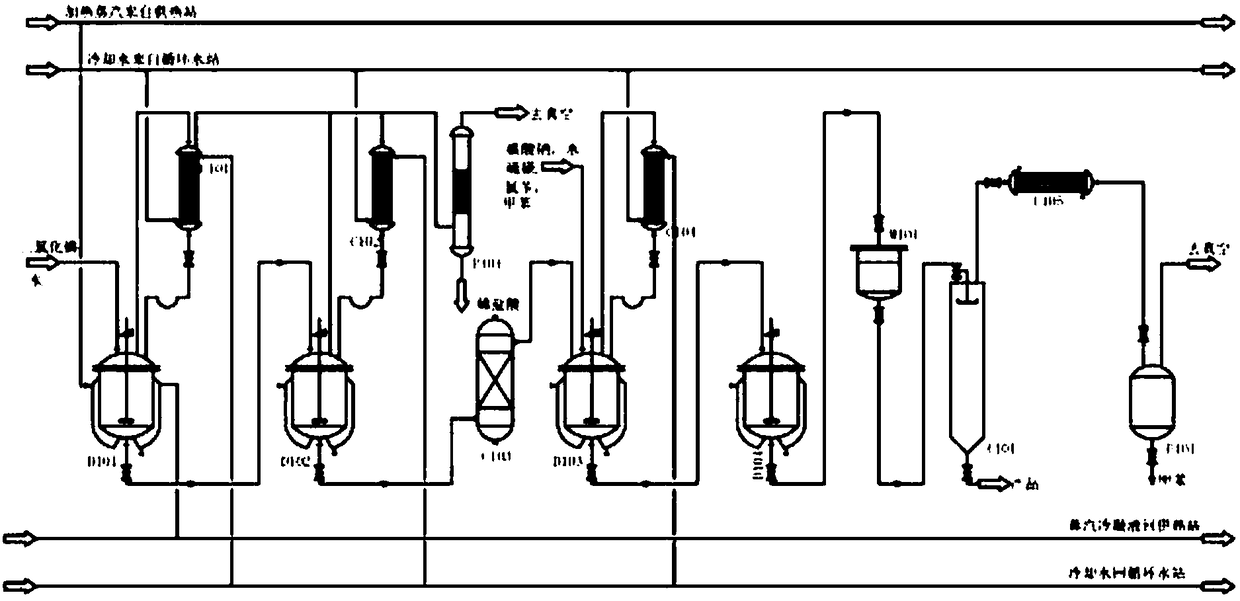

Image

Examples

example 1

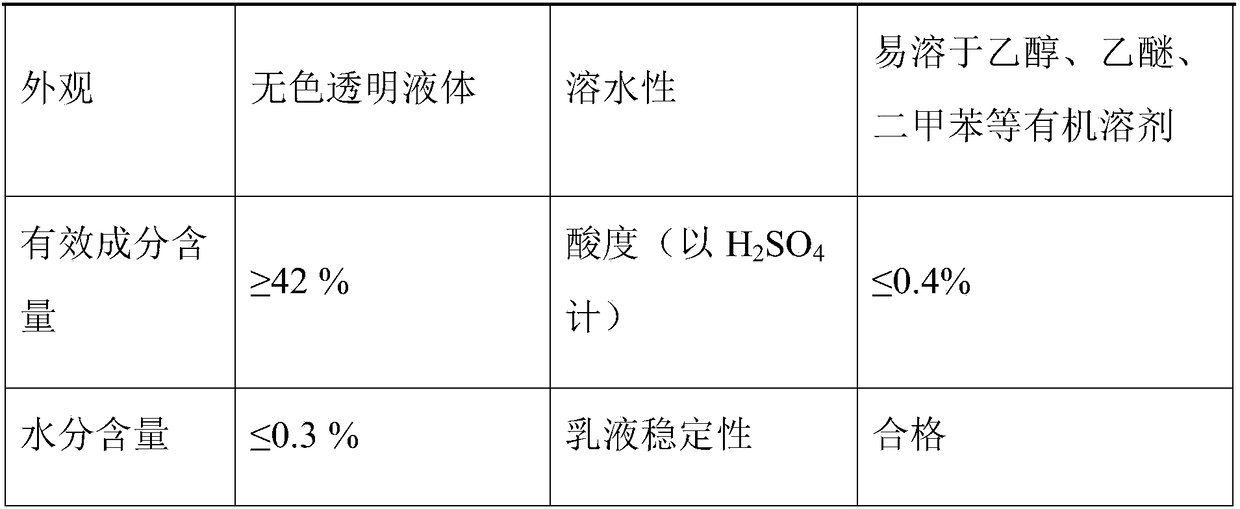

[0008] Production raw materials and dosage

[0009]

[0010] The production equipment of diisopropyl-S-benzyl phosphoric acid sulfide mainly includes: reaction kettle (D101), condenser (C101), deacidification kettle (D102), condenser (C102), tail gas absorption tower (E101) , condenser (C103), reaction kettle (D103), condenser (C104), static kettle (D104), filter (M101), membrane evaporator (L101), condenser (C105), receiver (F101) , wherein the condenser (C103) is connected to the deacidification kettle (D102) and the reaction kettle (D103) respectively, and the filter (M101) is connected to the static kettle (D104) and the diaphragm evaporator (L101) respectively, wherein, Reactor (D101) jacket capacity 330L, condenser (C101) heat exchange tube diameter 0.017m, reactor (D103) inner pot diameter 930mm.

[0011] The production device of diisopropyl-S-benzyl phosphoric acid sulfide, the production process is as follows: add ethanol and phosphine trioxide continuously into t...

example 2

[0015] Production raw materials and dosage

[0016]

[0017] The production equipment of diisopropyl-S-benzyl phosphoric acid sulfide mainly includes: reaction kettle (D101), condenser (C101), deacidification kettle (D102), condenser (C102), tail gas absorption tower (E101) , condenser (C103), reaction kettle (D103), condenser (C104), static kettle (D104), filter (M101), membrane evaporator (L101), condenser (C105), receiver (F101) , wherein the condenser (C103) is connected to the deacidification kettle (D102) and the reaction kettle (D103) respectively, and the filter (M101) is connected to the static kettle (D104) and the diaphragm evaporator (L101) respectively, wherein, Reactor (D101) jacket capacity 360L, condenser (C101) heat exchange tube diameter 0.019m, reactor (D103) inner pot diameter 990mm.

[0018] The production device of diisopropyl-S-benzyl phosphoric acid sulfide, the production process is as follows: add ethanol and phosphine trioxide continuously into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com