Dry-type anaerobic reaction treatment device

A dry-type anaerobic treatment device technology, applied in the direction of biomass post-treatment, biomass pre-treatment, biochemical cleaning device, etc., can solve the problems of inability to further improve the degradation rate of organic waste, uneven heating temperature of materials, and degradation rate of organic matter Low-level problems, to achieve the effect of full fermentation, less processing units, and full degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

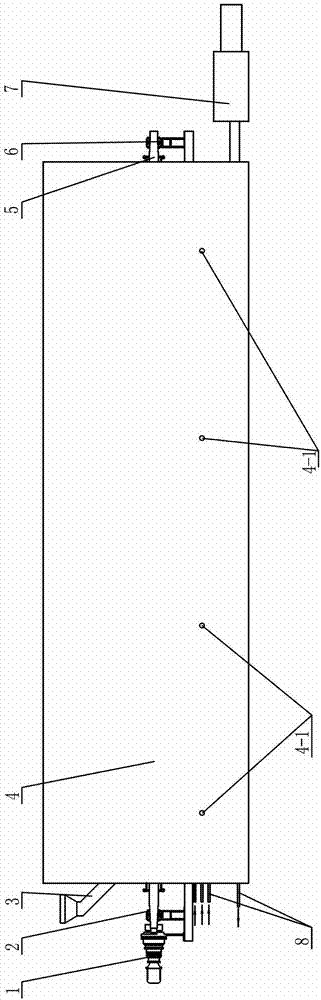

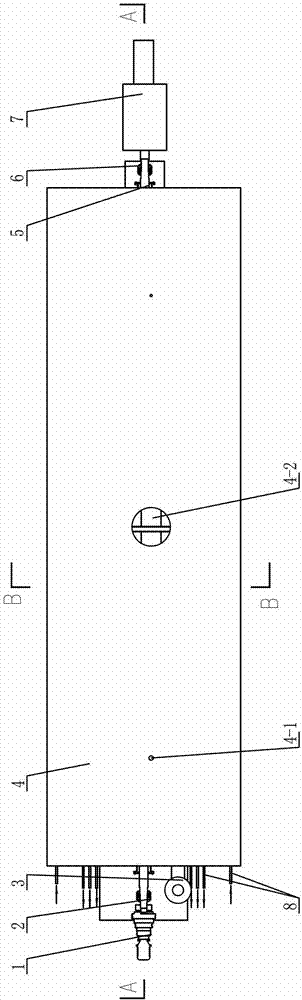

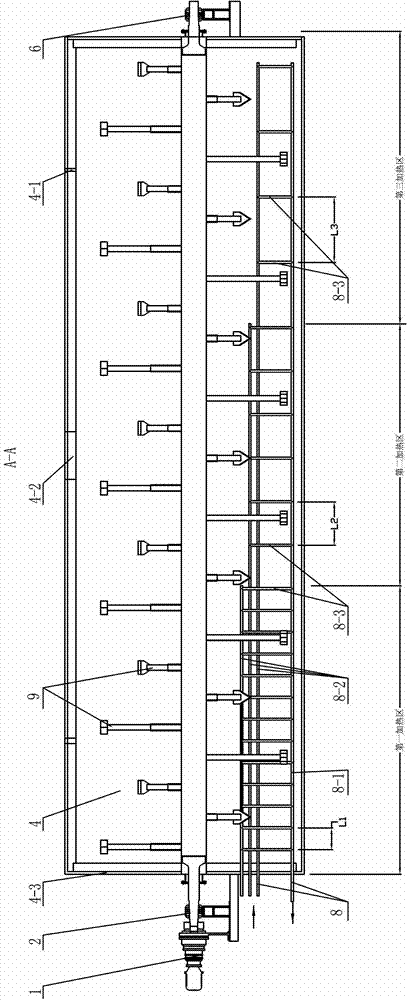

[0017] see Figure 1~6 As shown, the dry anaerobic reaction treatment device of the present invention includes a reaction vessel 4 and a stirring mechanism supported on the reaction vessel 4. The stirring mechanism includes a motor 1 and a stirring shaft 5, the stirring shaft 5 penetrates both sides of the reaction vessel 4, One end of the stirring shaft 5 is connected to the input shaft of the motor 1 and is supported on the front bearing housing 2 through a bearing. The other end of the stirring shaft 5 is supported on the rear bearing housing 6 located outside the reaction vessel 4 and driven by the motor 1 of the stirring mechanism The stirring shaft 5 rotates. The motor 1 of the present invention has a reducer, which can control the stirring speed at 0.3-1.5r / min, and consumes very low power. It can be continuous or intermittent according to changes in parameters such as gas production and temperature. Stir in.

[0018] see Figure 1~5 As shown, one side of the reaction vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com