Reinforced mixed type gas low-nitrogen burner for aluminum hydroxide roasting furnace

A low-nitrogen burner, aluminum hydroxide technology, which is applied to gas fuel burners, combustion with multiple fuels, burners, etc., can solve the problems of secondary pollution of ammonia environment and high cost, and achieve small system changes and workload. Small, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

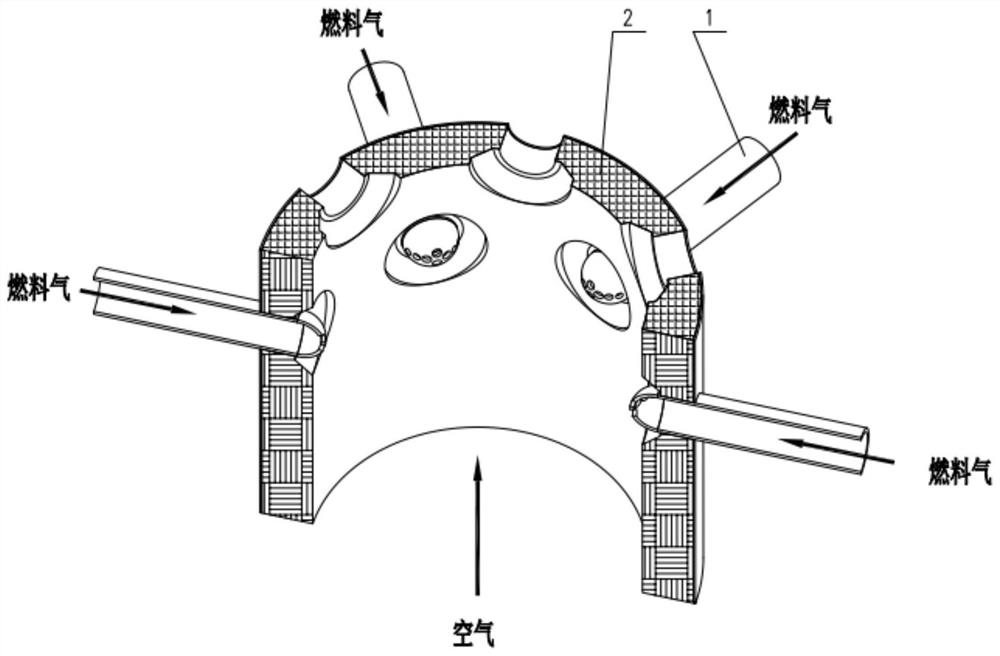

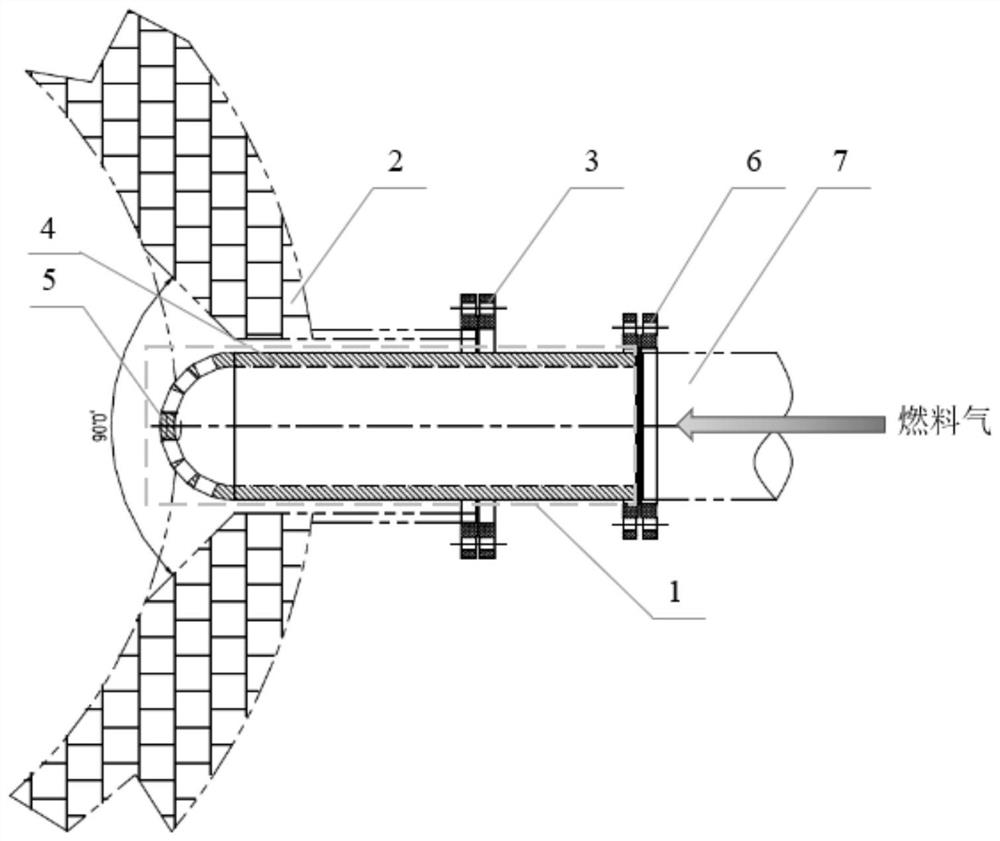

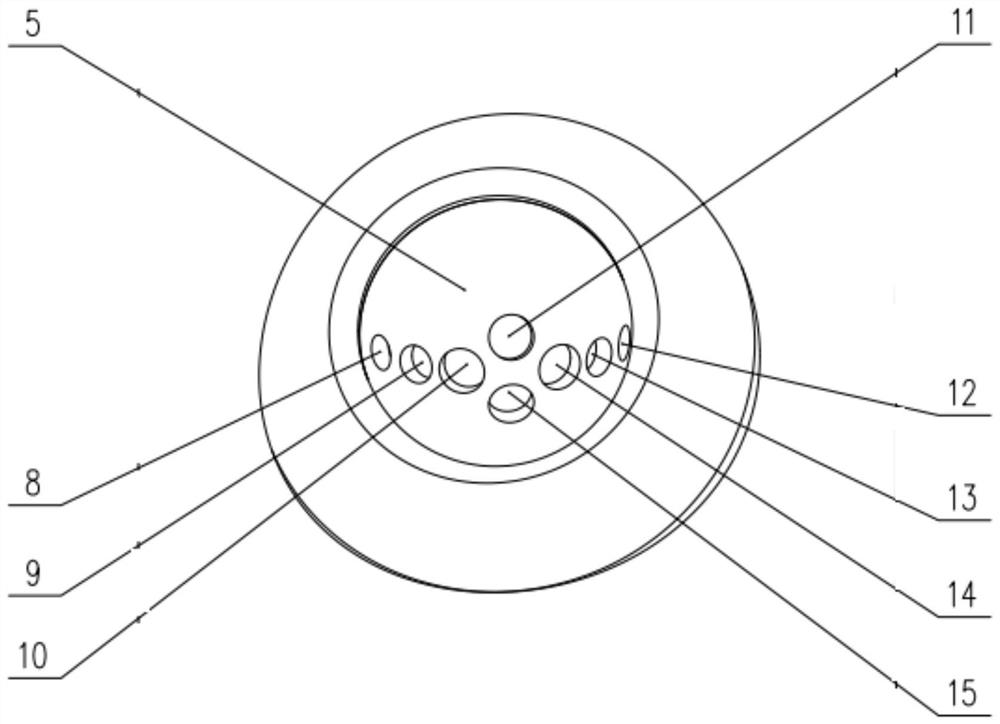

[0028] Such as Figure 1-Figure 3 As shown, an enhanced mixed gas low-nitrogen burner for an aluminum hydroxide roaster includes a burner body 1, and the burner body 1 is fixed on the furnace wall 2 through a flange 3, and the burner The body 1 includes a burner barrel 4 and a burner tip 5, the end of the burner barrel 4 is communicated with the fuel gas supply pipe 7 through a flange 2 6, and the head end of the burner barrel 4 is connected to the burner gun The head 5 is fixedly connected, the burner gun head 5 extends into the furnace wall 2, and a number of gas injection holes are opened on the spherical surface of the burner gun head 2, and the sum of the area of the gas injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com