A kind of synthetic method of aqueous polyurethane heterogeneous chain extension

A technology of water-based polyurethane and synthesis method, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of low allophanate content, inability to obtain high-temperature-resistant, high-hardness water-based polyurethane emulsion, small usage, etc. problems, to achieve the effect of improving the leveling performance, effectively controlling the reaction heat, and increasing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

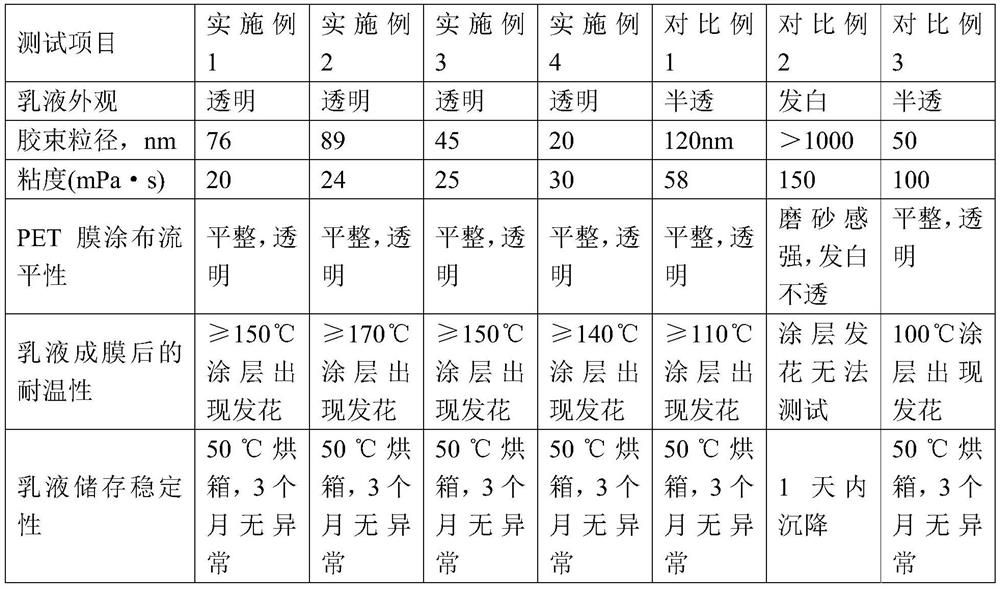

Examples

Embodiment 1

[0046] The present invention relates to a kind of preparation method of the aqueous polyurethane resin of heterogeneous chain extension, comprises the following steps:

[0047] (1) Add 367 parts of adipic acid polyester diol with a number average molecular weight of 2000 to a drying reactor equipped with a stirrer, a thermometer, and a reflux condenser, raise the temperature to above 100° C., and dehydrate to obtain material a.

[0048] (2) Add 326 parts of isophorone diisocyanate, heat up to 80° C. and carry out polymerization reaction for 3 hours to obtain material b;

[0049] (3) When the mass percent content of isocyanate groups in material b reaches 15.6%, add 47 parts of dimethylolpropionic acid to material b, maintain the temperature at 75-80°C, add 26 parts of trimethylolpropane, 150 Part of acetone, insulation 3h obtains material c;

[0050] (4) When the mass percent content of isocyanate groups in the material c reaches 6.4%, add 30 parts of triethylamine and 200 pa...

Embodiment 2

[0056] The present invention relates to a kind of preparation method of the aqueous polyurethane resin of heterogeneous chain extension, comprises the following steps:

[0057] (1) Add 244 parts of adipic acid polyester polyol with a molecular weight of 2000 to a drying reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, raise the temperature to above 100° C., and dehydrate to obtain material a.

[0058] (2) Add 410 parts of isophorone diisocyanate, heat up to 80° C. and carry out polymerization reaction for 3 hours to obtain material b;

[0059] (3) When the mass percent content of isocyanate in material b reaches 22%, add 69 parts of dimethylol propionic acid to material b, add 10 parts of trimethylolpropane, 400 parts of acetone, and maintain the temperature at 75-80 ℃, heat preservation for 3h to obtain material c;

[0060] (4) When the mass percent content of isocyanate groups in the material c reaches 8.5%, add 50 parts of triethylamine and 40...

Embodiment 3

[0066] The present invention relates to a kind of preparation method of the aqueous polyurethane resin of low solvent consumption, comprises the following steps:

[0067] (1) Add 123 parts of polycarbonate diol with a molecular weight of 1000 to a dry reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, raise the temperature to above 100° C., and dehydrate to obtain material a.

[0068] (2) Add 170 parts of diphenylmethane diisocyanate, heat up to 70-90°C to carry out polymerization reaction for 2-4 hours to obtain material b;

[0069] (3) When the content of isocyanate groups in material b reaches 17.6% (mass ratio), add 20 parts of dimethylol butyric acid to material b, maintain the temperature at 75-80°C, and add 8 parts of trimethylolethane , 180 parts of acetone, heat preservation for 3h to obtain material c;

[0070] (4) When the isocyanate group content in material c reaches 7.0% (mass ratio), add 12 parts of N, N dimethylethanolamine and 20 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com