Flat dispersion flame low NOx gas heat storage combustion device

A gas heat storage and combustion device technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems that flue gas cannot enter the combustion area and the content of NOx is high, and achieves simple structure, increased contact area, even burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

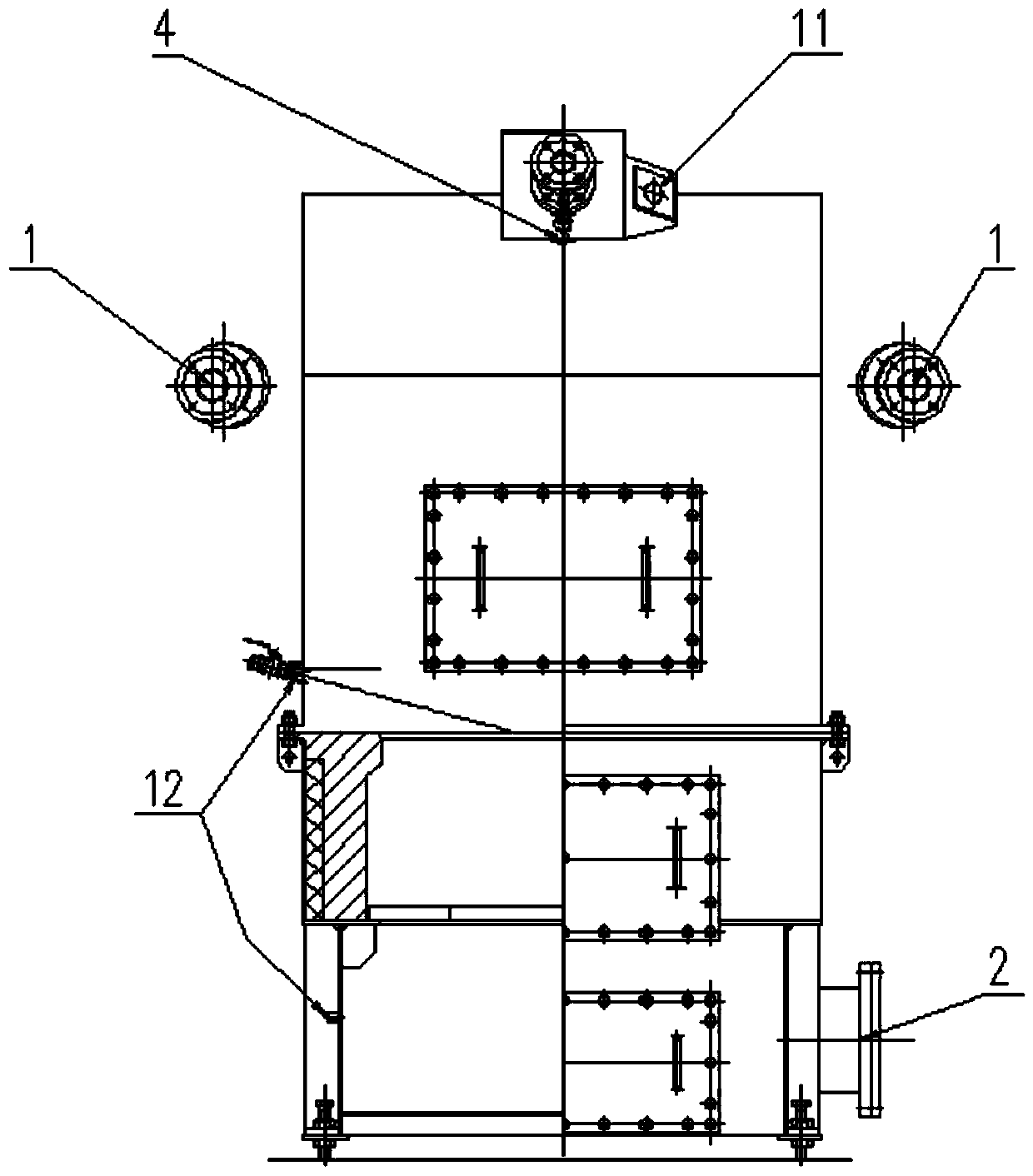

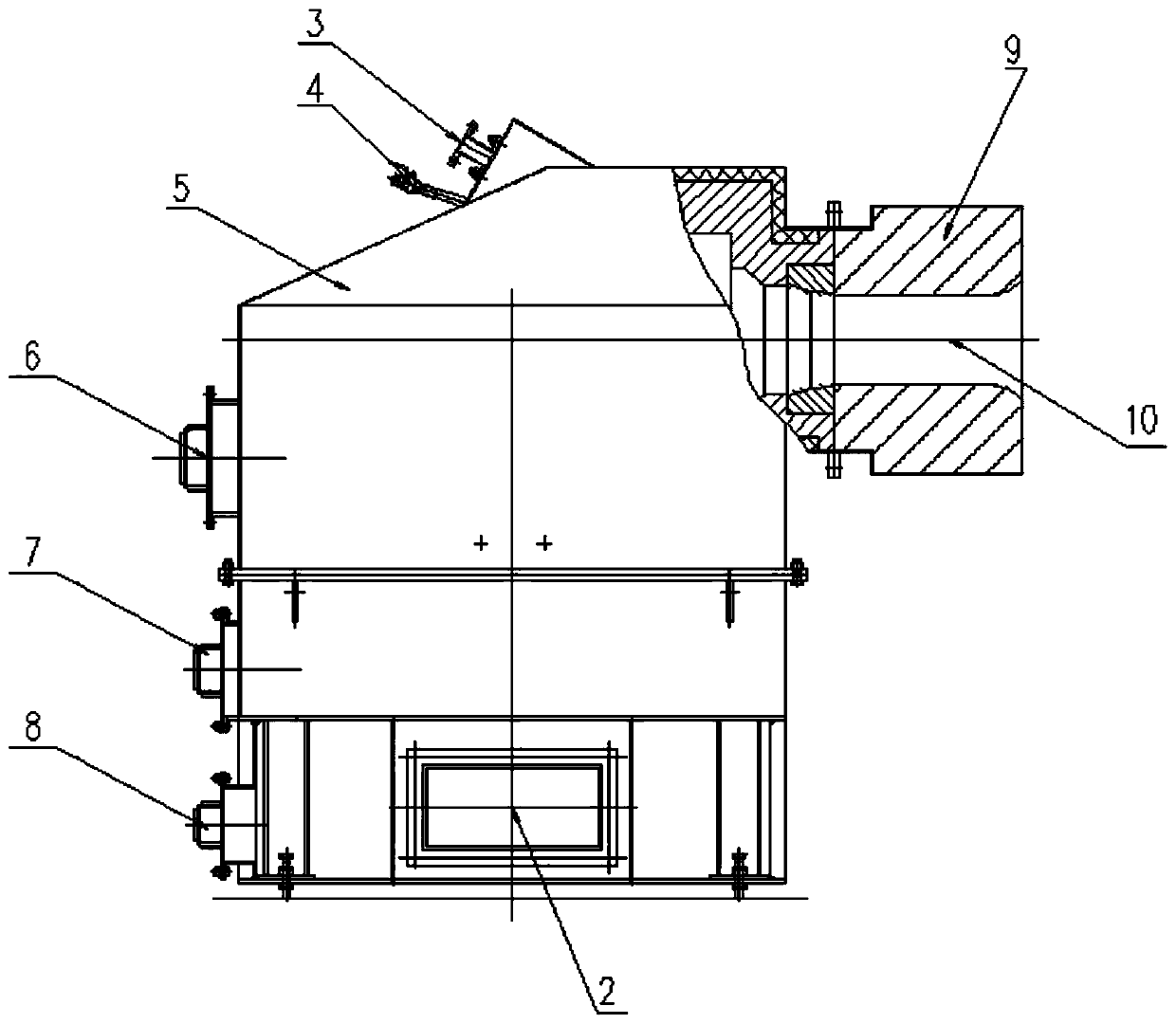

[0020] The present invention is described below with reference to the accompanying drawings. Of course, the present invention is not limited to this example, and other changes and innovations in other forms can also be made according to specific conditions.

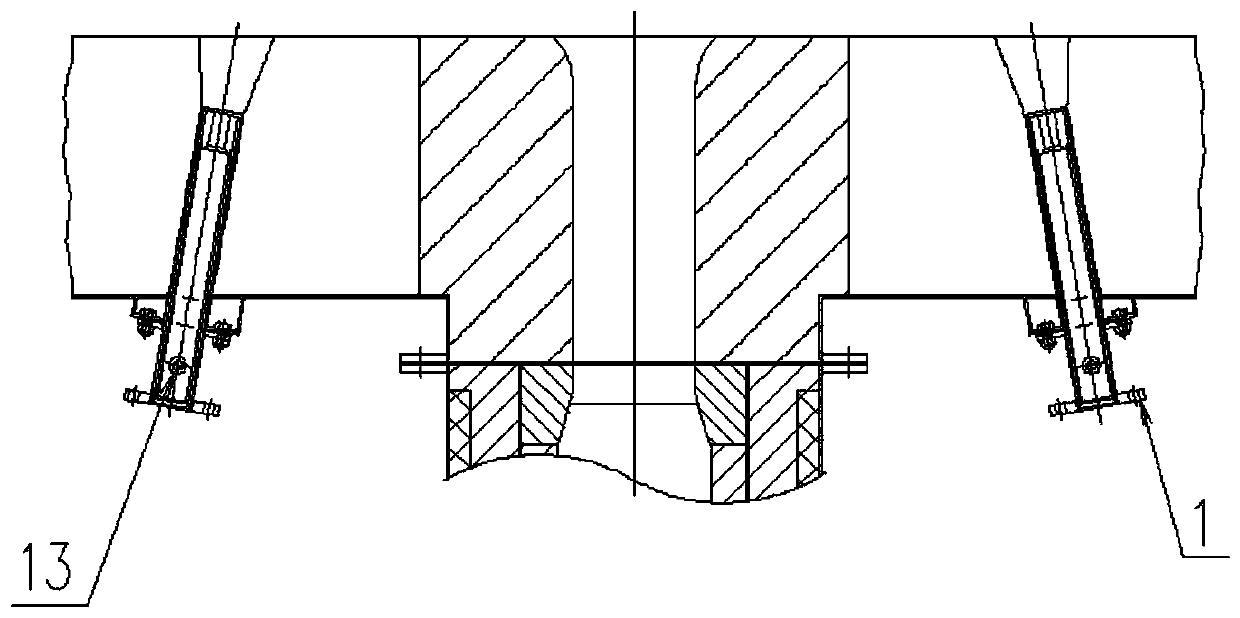

[0021] The device of the present invention includes a gas nozzle 1, an air inlet / smoke outlet 2, an ignition gas nozzle 3, a flame detector interface 4, a thermal storage tank 5, a thermal storage body loading port 6, a thermal storage body extraction outlet 7, a thermal storage body Slag discharge port 8, burner brick 9, air / smoke gas nozzle 10, ignition electrode interface 11, flue gas temperature detection port 12, gas nozzle cooling air 13.

[0022] The flame detector interface 4 and the ignition electrode interface 11 are installed on the ignition gas nozzle 3 to form an ignition device. The ignition device is installed on the upper part of the heat storage tank 5 . The air inlet / flue gas outlet 2 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com