Method for preparing three-dimensional heat dissipation film and three-dimensional heat dissipation film

A heat dissipation film and composite heat dissipation film technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of reduced heat dissipation efficiency and cumbersome placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

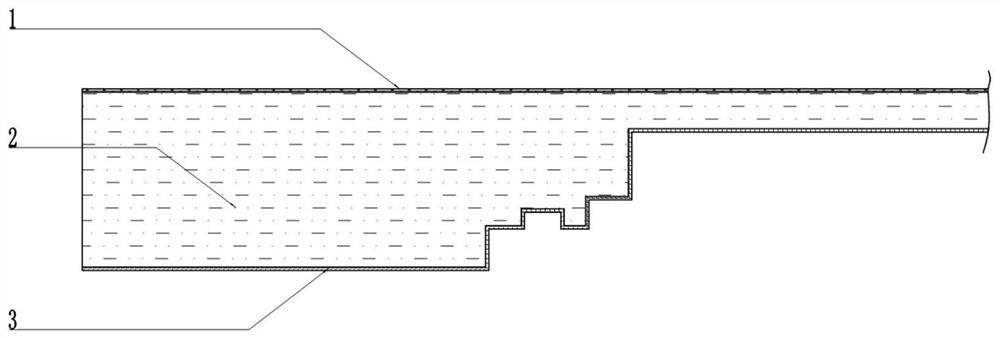

[0040] In this embodiment, a method of layered die-cutting and longitudinal lamination is adopted to form a depression matching the three-dimensional shape of the heat dissipation surface.

[0041] In advance, according to the heat dissipation design requirements, the material and thickness of the three-dimensional heat dissipation film are designed, as well as the specific number of single-layer heat dissipation films and the thickness specifications of each single-layer heat dissipation film, and then the three-dimensional shape of the heat dissipation surface is determined according to the single-layer heat dissipation film and the thickness specification of each single-layer heat dissipation film. The thickness of each single-layer heat dissipation film is divided into corresponding layers, and each single-layer heat dissipation film corresponds to a layer, and then the shape of each layer is obtained;

[0042] Then, according to the designed outline of the three-dimensiona...

Embodiment 2

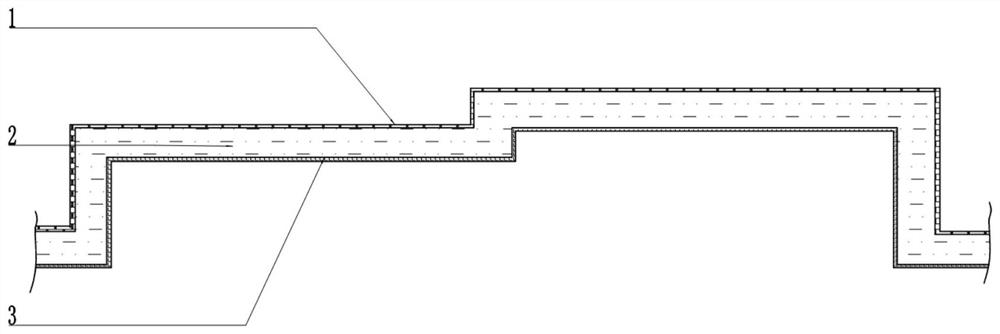

[0048] For some heating components with irregular heat dissipation surfaces, the height difference in the three-dimensional shape of the heat dissipation surface is relatively large, but the heat dissipation design requirements do not require very many (thick) multi-layer composite heat dissipation films, so only use Embodiment 1 The method in the method to shape the depression that matches the three-dimensional shape of the heat dissipation surface will cause waste of material, because the number of layers / thickness of the three-dimensional heat dissipation film in embodiment one depends on the height of the highest point in the three-dimensional shape; in addition, if the heating element The installation space of the device itself is limited. For example, there is an intermittent fit between the installation space and the heat dissipation surface of the heating element, so the space left for the multilayer composite heat dissipation film is extremely limited.

[0049] However...

Embodiment 3

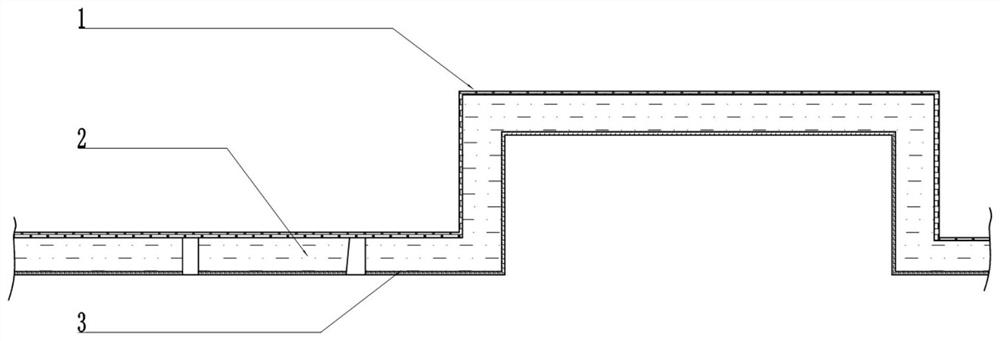

[0058] In this embodiment, layered die-cutting and longitudinal lamination are used to form a depression matching the three-dimensional shape of the heat dissipation surface, and then molding is used to form the remaining depressions.

[0059] In advance, according to the heat dissipation design requirements, the material and thickness of the three-dimensional heat dissipation film are designed, as well as the specific number of single-layer heat dissipation films and the thickness specifications of each single-layer heat dissipation film, and then the lower part of the three-dimensional shape of the heat dissipation surface (required The shallower depression and its dominance) are divided into corresponding layers according to the thickness of the single-layer heat dissipation film and each single-layer heat dissipation film, and each single-layer heat dissipation film corresponds to a layer, and then the shape of each layer is obtained; The three-dimensional shape of the rest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com