Hollow ceramic core stuffing method for expendable pattern precision casting

A technology of investment precision casting and hollow ceramics, which is applied in the field of hollow ceramic core filling and hollow ceramic core filling, can solve problems such as metallurgical defect risks, achieve excellent process stability, reduce loose tendency of castings, and reduce local Effect of heat festival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

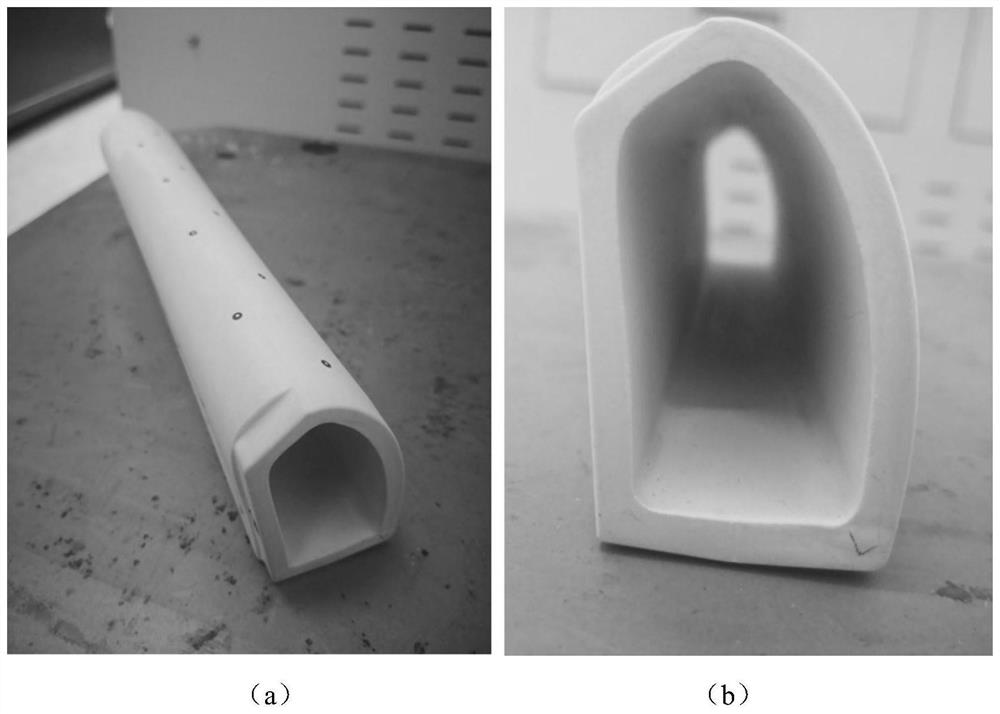

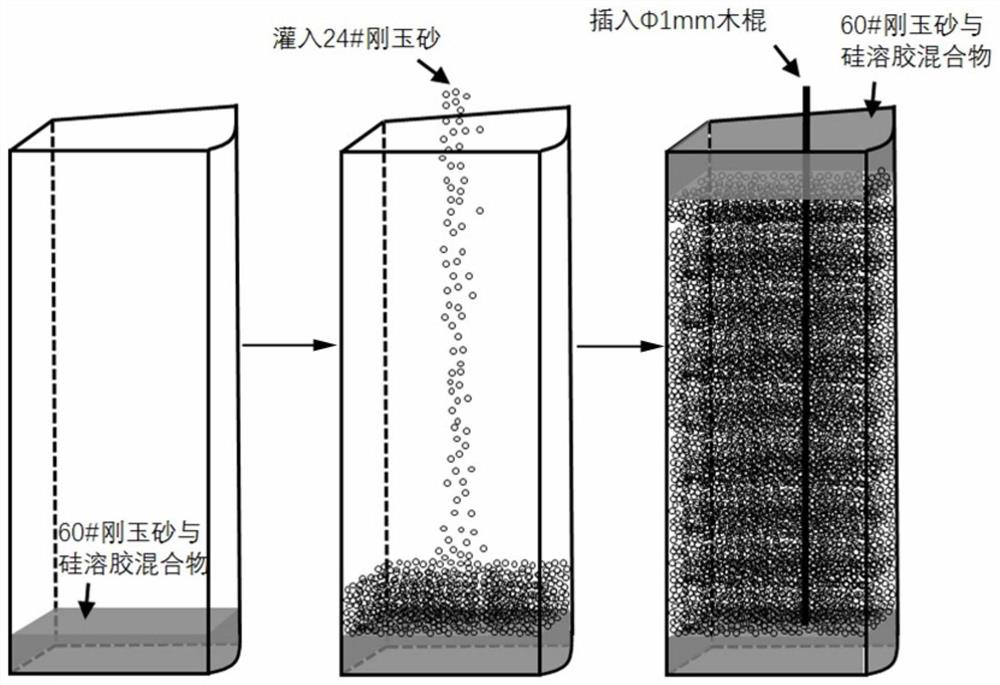

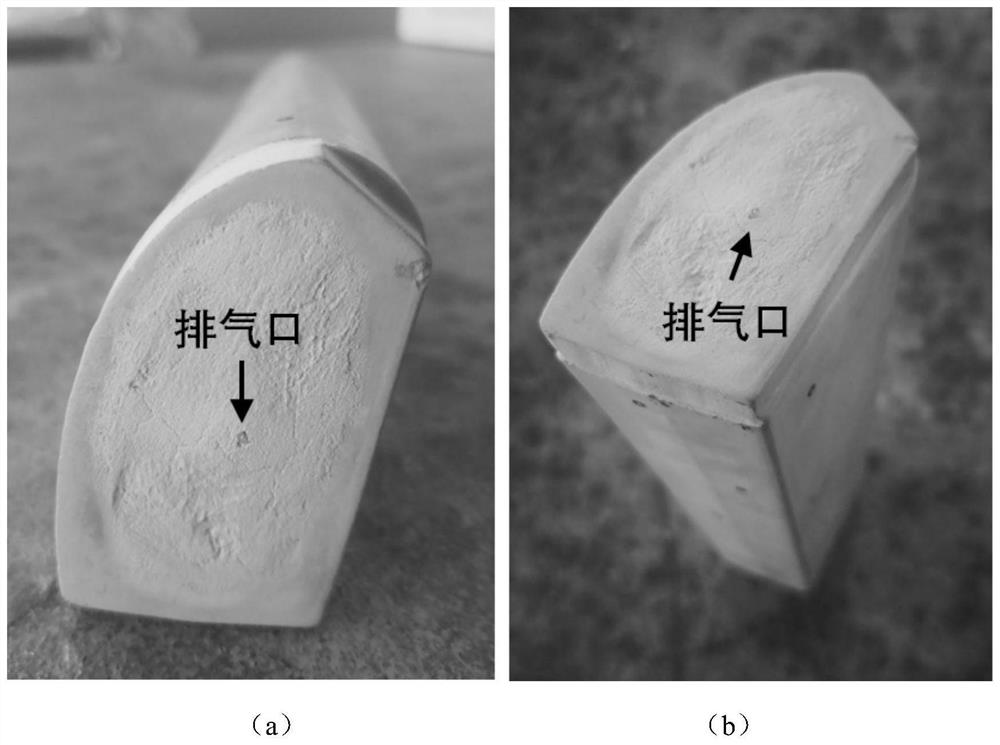

[0028] This embodiment is to fill the cavity of the hollow ceramic core used in investment precision casting. The hollow ceramic core is as follows: figure 1 shown. The filling process is as figure 2 , including the following steps:

[0029] Step S1: Clean the surface of the hollow ceramic core and place it vertically on a fixed plane for later use;

[0030] Step S2: Mix 100g of 60# corundum sand and 35ml of silica sol according to the ratio. After fully stirring, fill it to one end of the inner cavity of the core, and then seal it. The thickness of the sealing layer is about 10mm, and let it stand for 10 minutes;

[0031] Step S3: Pour dry 24# corundum sand into the inner cavity of the core, and keep moderately tamping it with a wooden stick during the filling process until the filling is 10mm away from the opening at the other end of the core. Use the stirred 60# corundum sand and silica sol mixture (the mixing ratio is the same as that in step S2) to seal the opening at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com