Method for casting super-large composite-material caststeel bearing roller above 100 ton

A composite material and super-large technology, which is applied in the casting field of composite material super-large cast steel support rolls above 100 tons, can solve the problems of strict equipment requirements, large amount of molten steel, and difficulty in casting and forming, so as to avoid tensile stress cracks, The effect of increasing the service life and reducing the height of the riser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

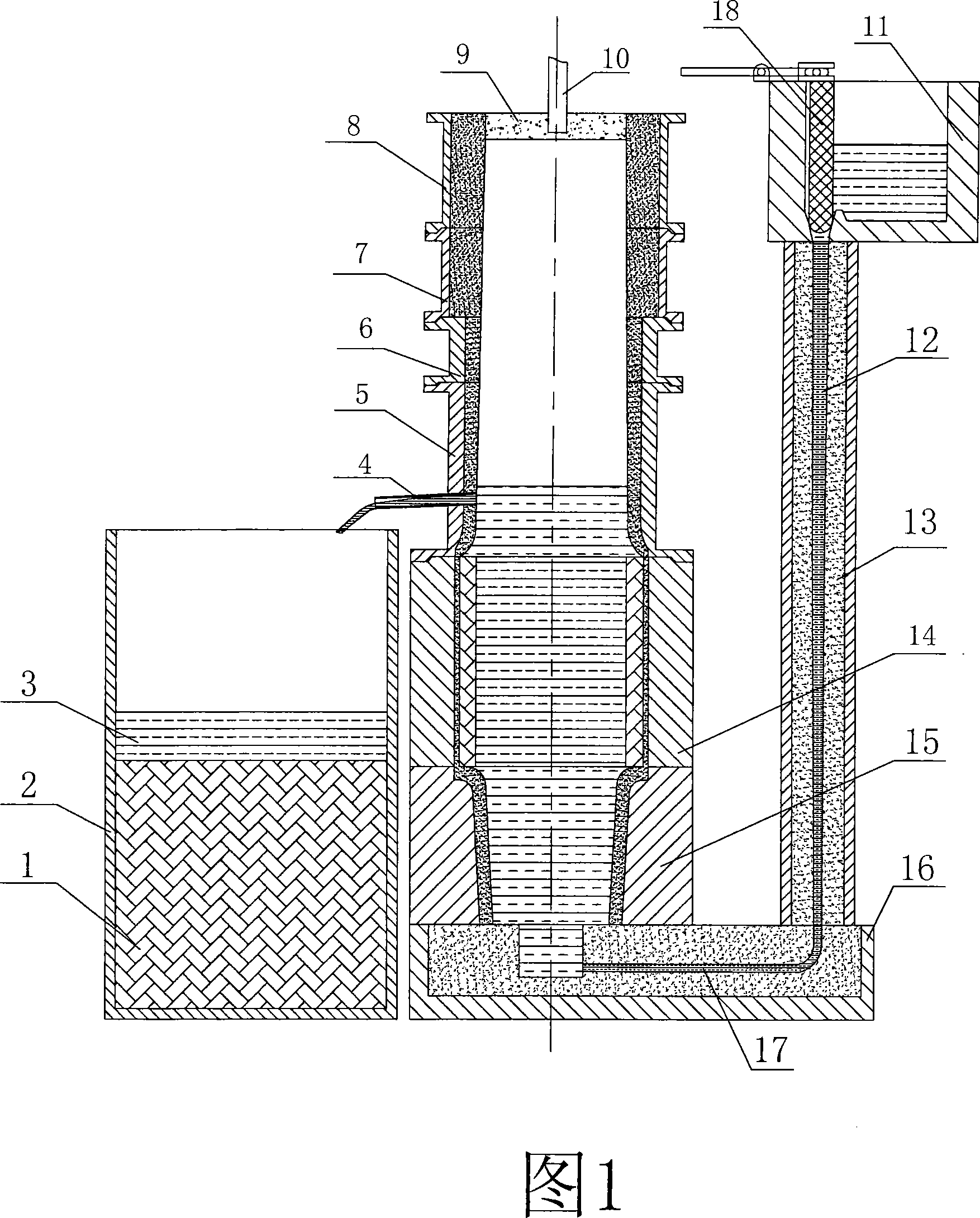

[0051] The first metal material used in this embodiment is Cr1, the second metal is No. 45 steel, and the weight of poured metal liquid is 150 tons. Its casting process is as follows:

[0052] 1) The pouring system adopts tangential inner gate rotary pouring, and the tundish and pouring system are designed according to the principle of smooth filling, and the runner insulation technology is adopted. 2) Composite riser, the height of the riser is 2800mm, of which the height of the sand mold is 1500mm, and the height of the refractory brick is 1300mm. 3) Using 4 times of boxing, 6 times of pouring, and 5 times of electric heating. The final electric heating after the molten metal fills the pouring system for 12 hours. 4) When assembling the mold for the first time, it is assembled to the first section box of the upper roll neck, and the first molten metal is poured through the designed smooth filling and pouring system, using double runners and filling at a pouring speed of 9 ...

Embodiment 2

[0055] The first metal material used in this embodiment is Cr2, the second metal is No. 45 steel, and the weight of poured metal liquid is 155 tons. Its casting process is as follows:

[0056] 1) The pouring system adopts tangential inner gate rotary pouring, and the tundish and pouring system are designed according to the principle of smooth filling, and the runner insulation technology is adopted. 2) Composite riser, the height of the riser is 2800mm, of which the height of the sand mold is 1500mm, and the height of the refractory brick is 1300mm. 3) Using 4 times of boxing, 6 times of pouring, and 5 times of electric heating. The final electric heating after the molten metal fills the pouring system for 13 hours. 4) When assembling the mold for the first time, it is assembled to the first section box of the upper roll neck, and the first molten metal is poured through the designed smooth filling and pouring system, using double runners and filling at a pouring speed of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com