Annular fuel element and annular fuel supercritical water reactor

A technology for fuel elements and fuel assemblies, applied in the field of reactors, can solve problems such as breakthrough of design limits, and achieve the effects of good moderation capacity, large heat exchange area, and reduction in quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

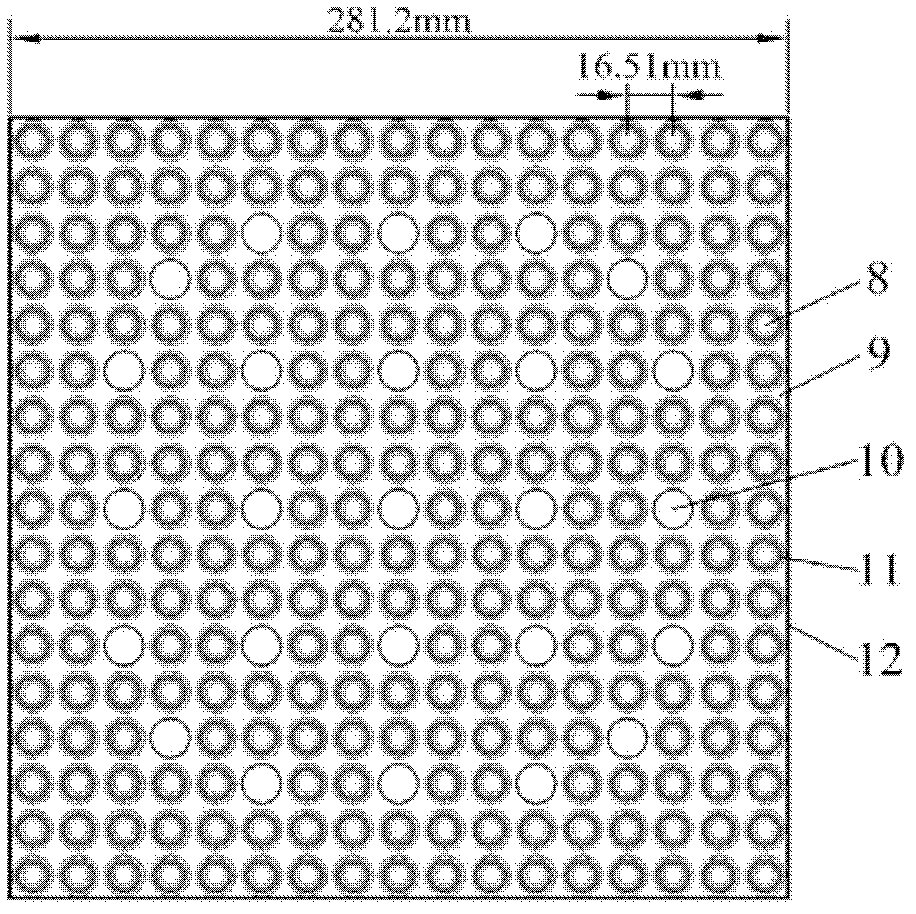

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

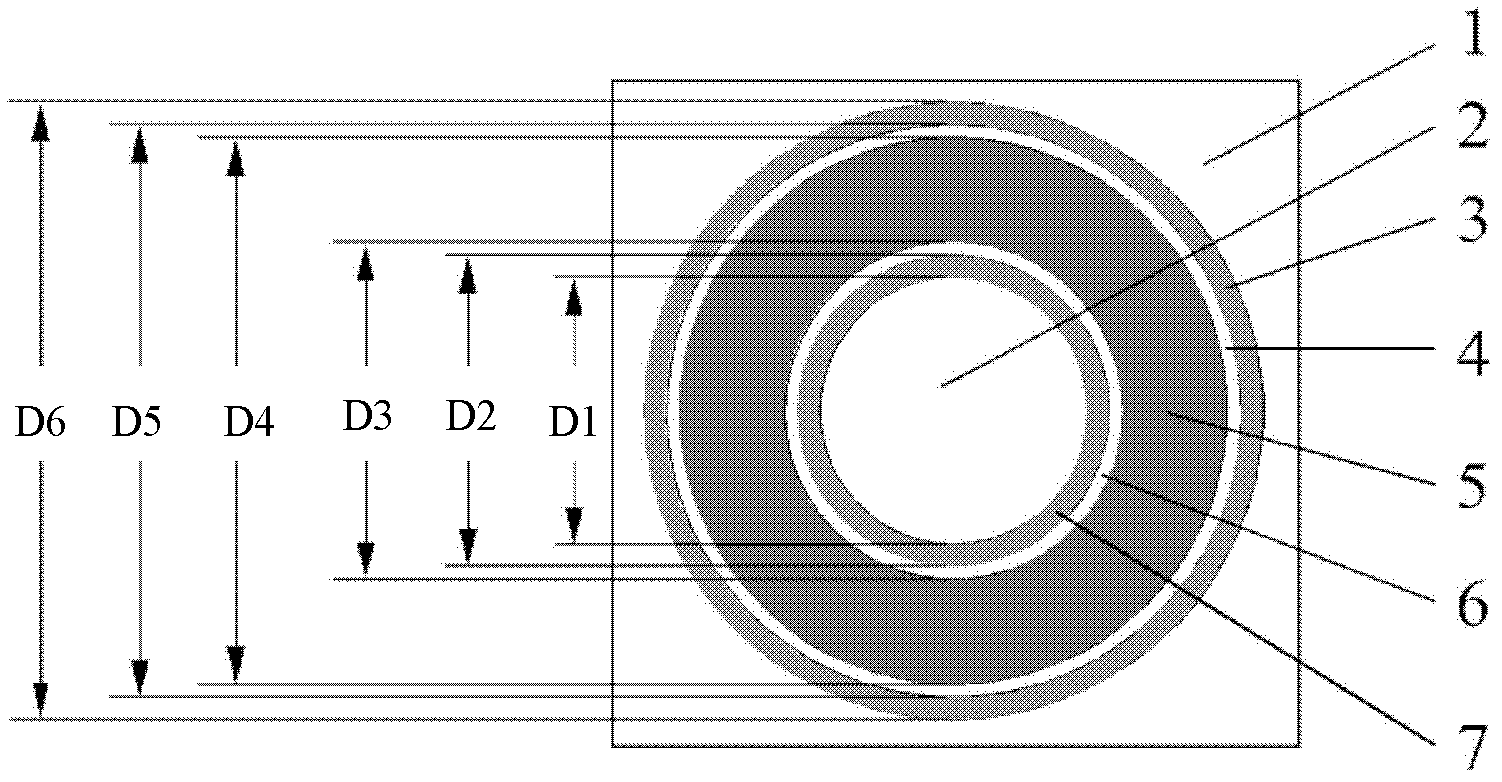

[0024] The present invention firstly proposes an annular fuel element 11, such as figure 1 As shown, the annular fuel element 11 is a cylindrical structure with an annular cross section, which is composed of an outer cladding 3, an outer air gap 4, fuel pellets 5, an inner air gap 6, and an inner cladding 7 from the outer layer to the inner layer. . The dimensions of each part are shown in the figure, and the diameters of the ring parts are D1, D2, D3, D4, D5, D6 respectively. In the preferred embodiment of the present invention, D1=8.63mm, D2=9.78mm, D3=9.90mm, D4=14.1mm, D5=14.2, D6=15.4.

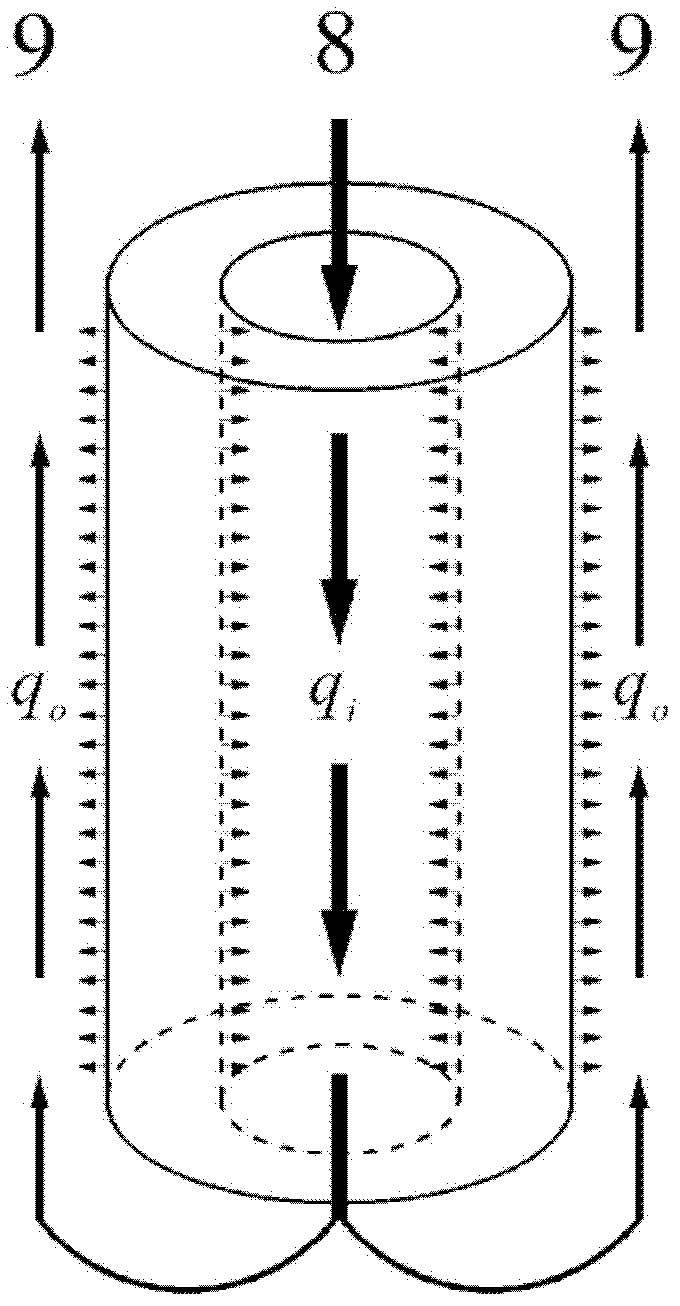

[0025] In this kind of annular fuel element, the coolant can flow through the outer passage 1 and the inner passage 2 of the annular fuel element simultaneously to cool the fuel pellets 5 . Compared with the existing rod-shaped fuel element, the annular fuel element has one mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com