Motor assembly and household appliance comprising motor assembly

A technology of motor components and household appliances, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., and can solve problems such as high temperature of the motor, no circulation, and affecting the life of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

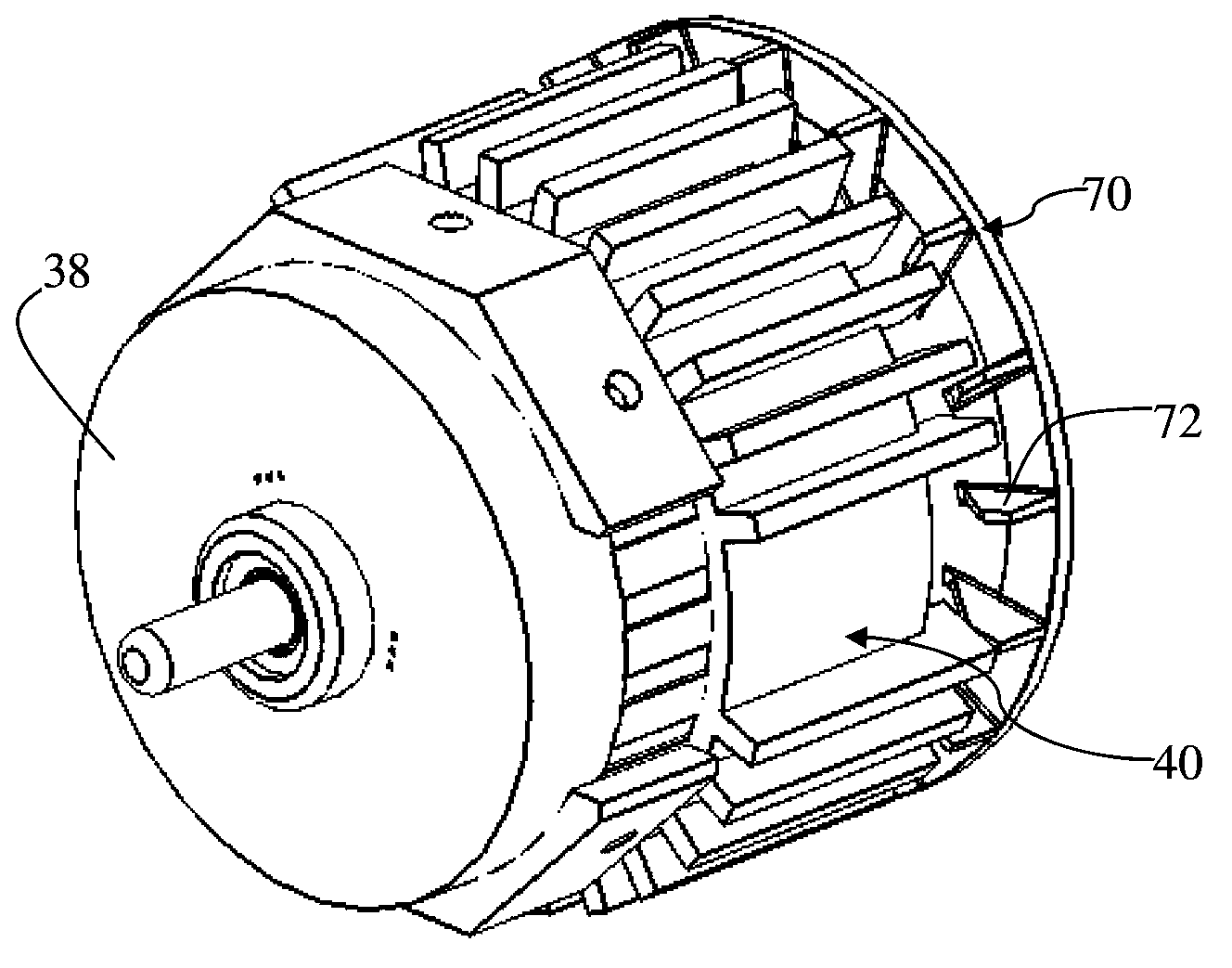

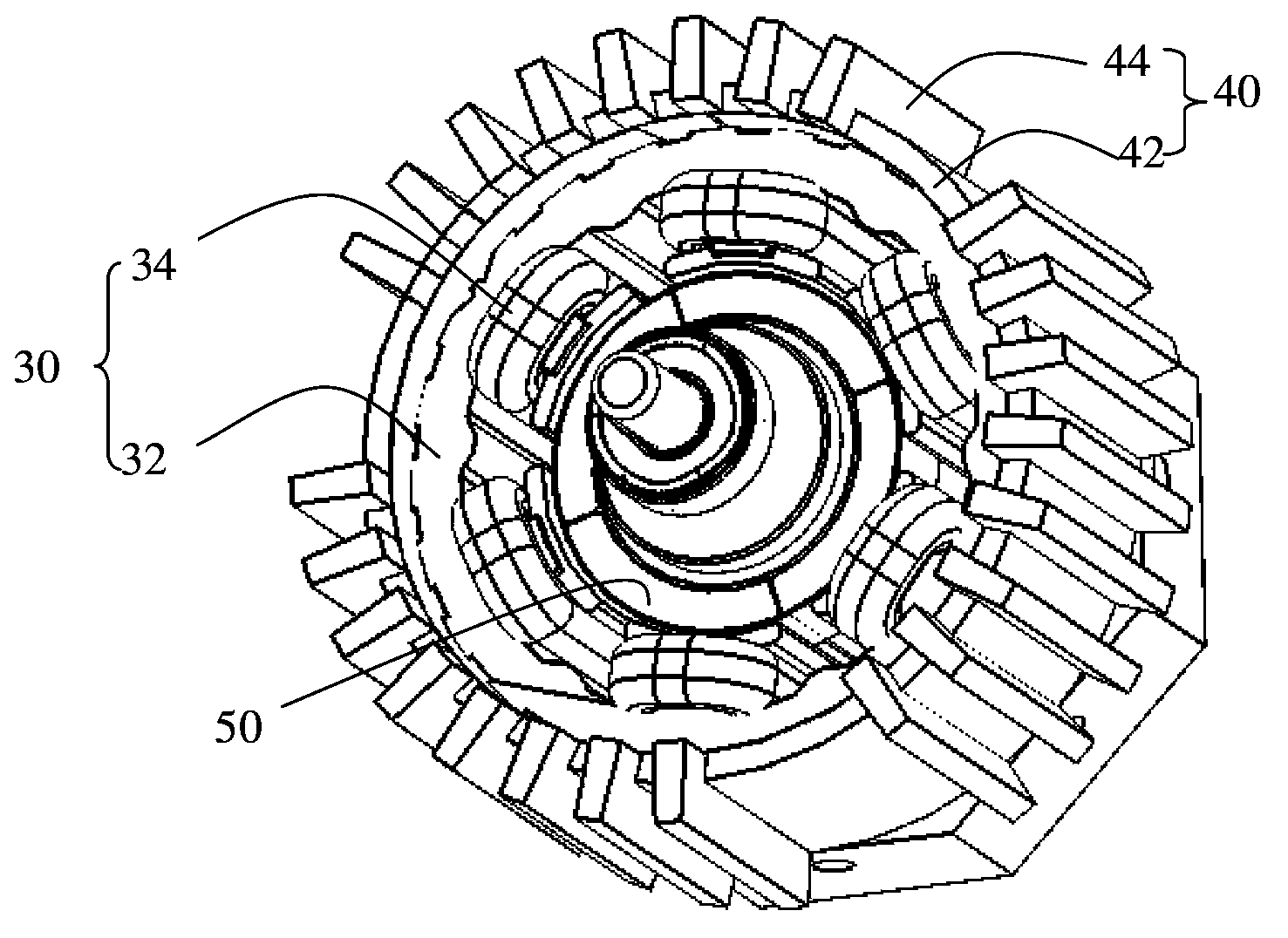

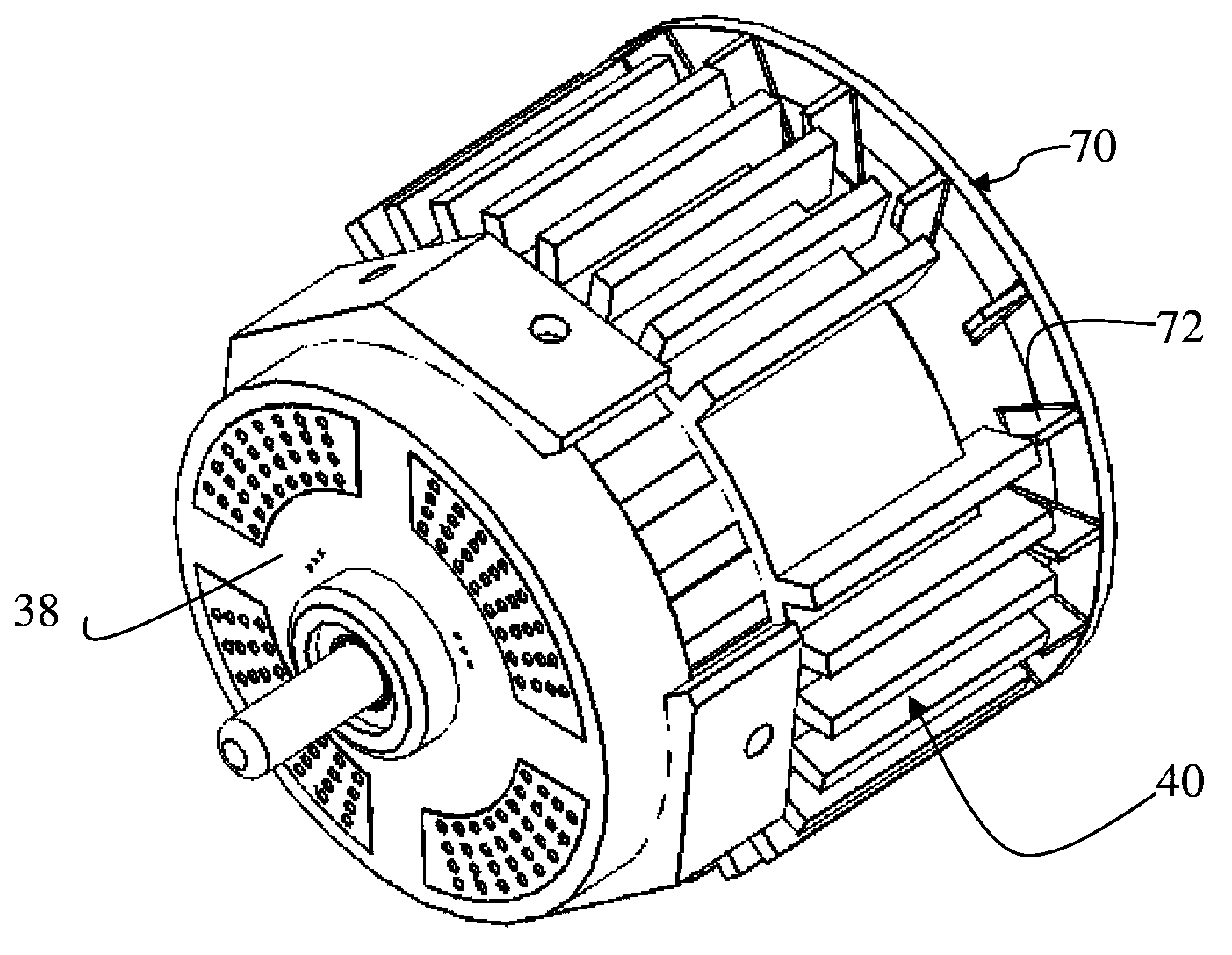

[0025] see figure 2 and image 3 , the motor 10 includes a stator 30 and a rotor 50 . According to an embodiment of the present invention, the motor is a brushless motor, and the stator 30 is located outside the rotor 50 . The stator 30 includes an iron core 32 and a winding 34 wound on the iron core 32 . Preferably, the iron core 32 includes a cylindrical yoke and a plurality of teeth extending radially inward from the yoke, and the winding 34 is wound on the corresponding teeth. The outer surface of the stator housing 32 is provided with a heat dissipation device 40 . The heat dissipation device 40 includes a cylindrical base 42 and a plurality of cooling fins 44 extending from the base 42 , the cooling fins 44 are distributed along the circumference of the motor at intervals, and each cooling fin 44 extends along the axial direction of the motor. The base 42 of the heat sink 40 is placed on the outer surface of the iron core 32, and the outer surface of the yoke of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com