Strong loop quick cooling chamber

A rapid cooling and strong circulation technology, applied in furnace cooling, lighting and heating equipment, furnace components, etc., can solve the problems of easy generation of turbulent flow, affecting the heat treatment effect of workpieces, difficult to control the gas flow in the cooling chamber, etc., to eliminate blind spots and The effect of eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment adopting the technical solution of the present invention is listed below in conjunction with the accompanying drawings.

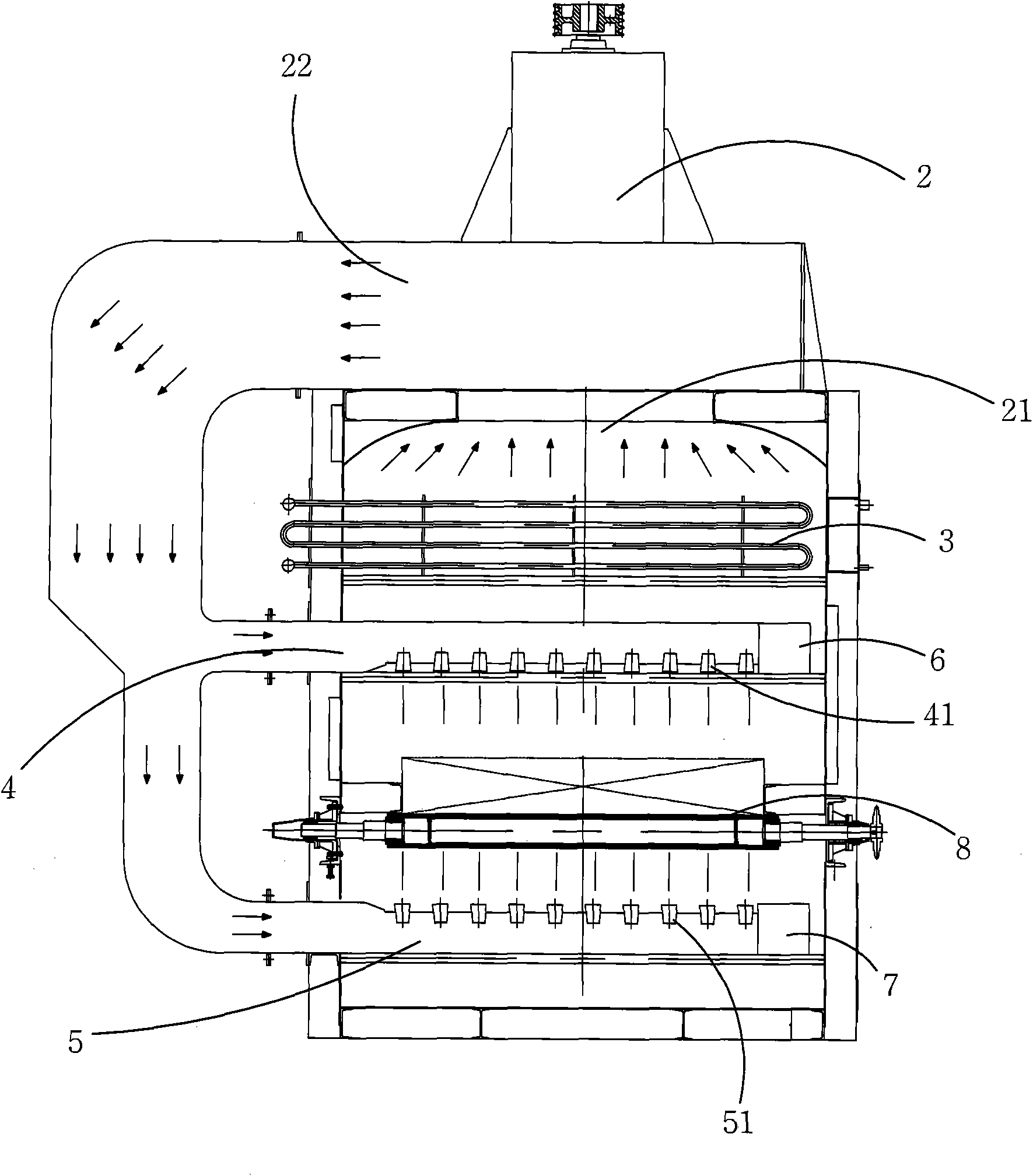

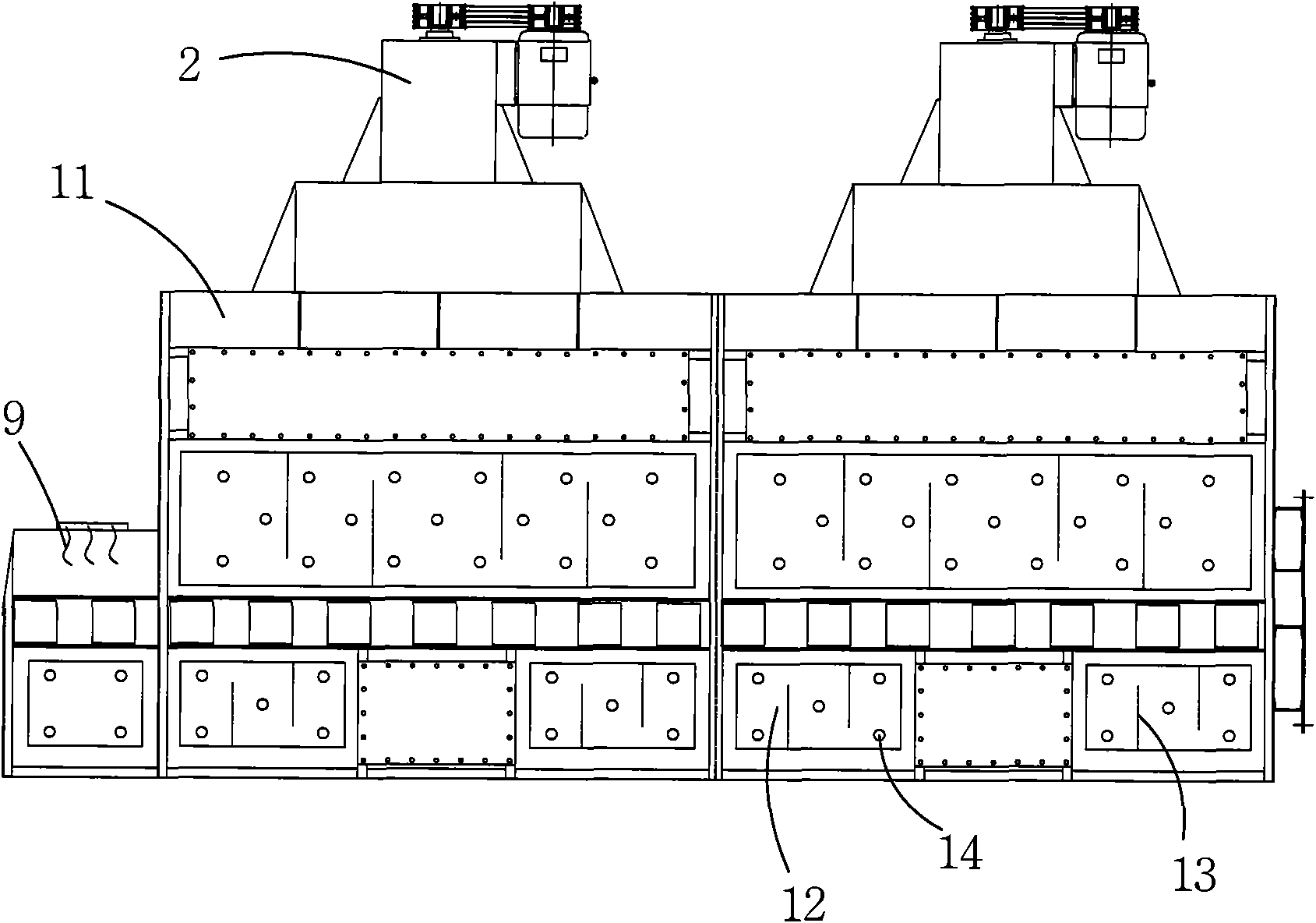

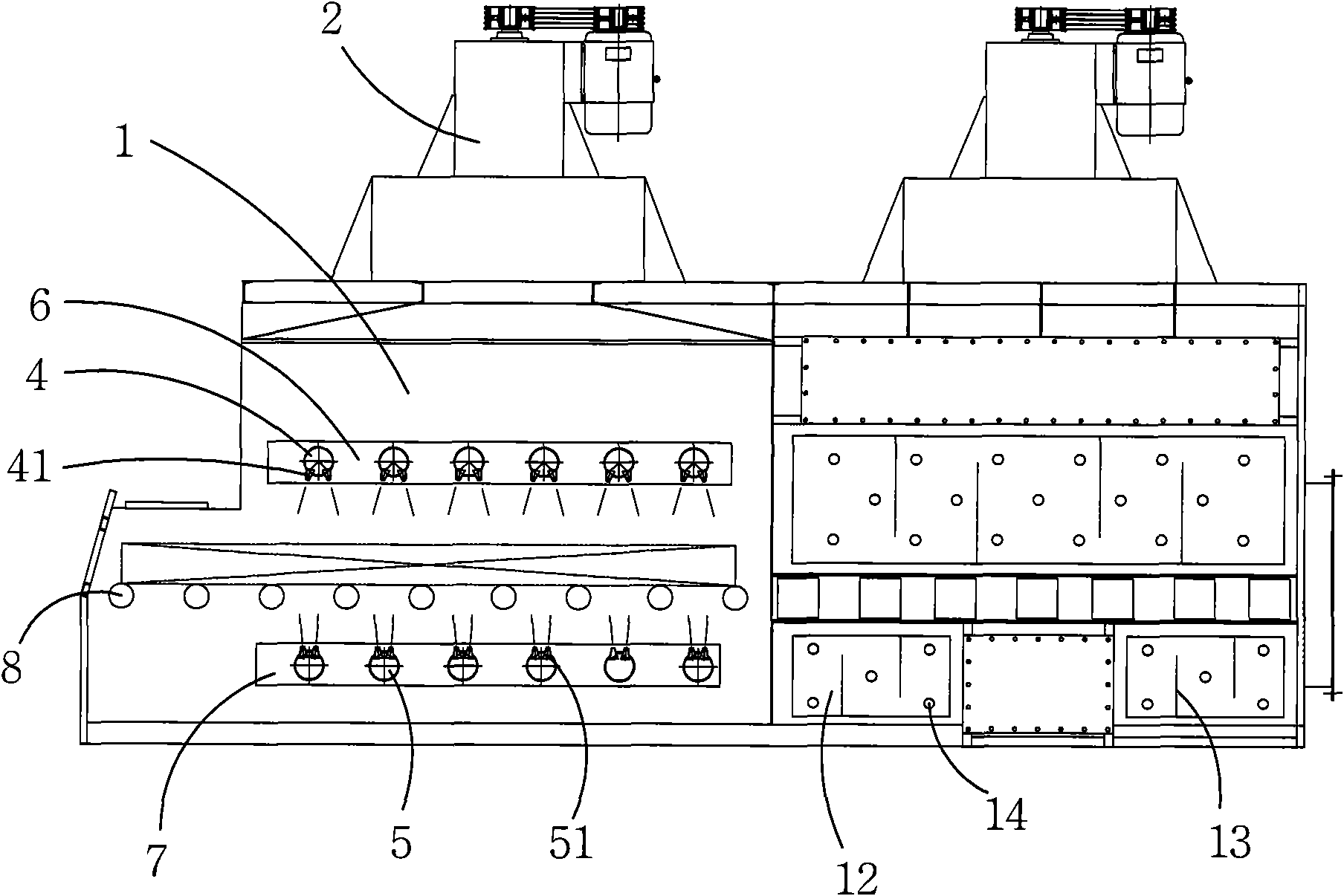

[0017] Such as Figure 1 to 3 As shown in the schematic diagram of the cooling device, the inside is an air-cooled chamber 1, a horizontal assembly line 8 runs through the air-cooled chamber 1, and the horizontal assembly line 8 carries animal feed through the air-cooled chamber 1. Inside the air-cooled chamber 1, an upper air duct assembly is provided above the horizontal assembly line 8, and a lower air duct assembly is provided below the horizontal assembly line 8. As shown in the figure, the upper air duct assembly includes six upper air ducts 4, which are arranged in parallel above the horizontal pipeline 8, and the pipe wall of each upper air duct 4 is evenly arranged along the axial direction. Several upper nozzles 41 capable of blowing downward air. The down duct assembly includes six down ducts 5, and a plurality of lower no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com