One-in and one-out double water-cooling sealing motor

A motor and double water-cooling technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of complicated motor water connection, many motor dripping points, and troublesome water connection, so as to improve the fixed performance, reduce the workload, Effect of Reliability Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

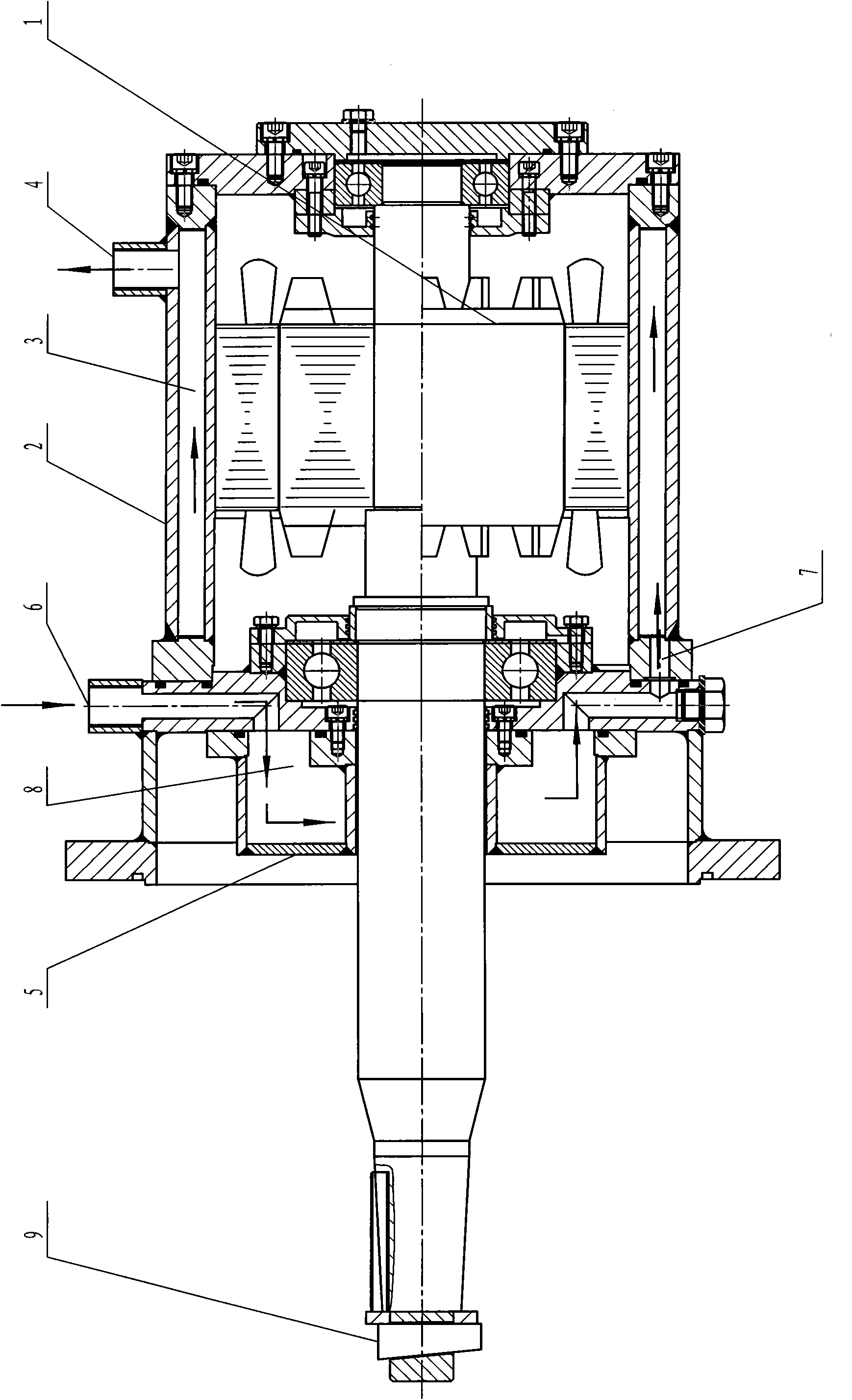

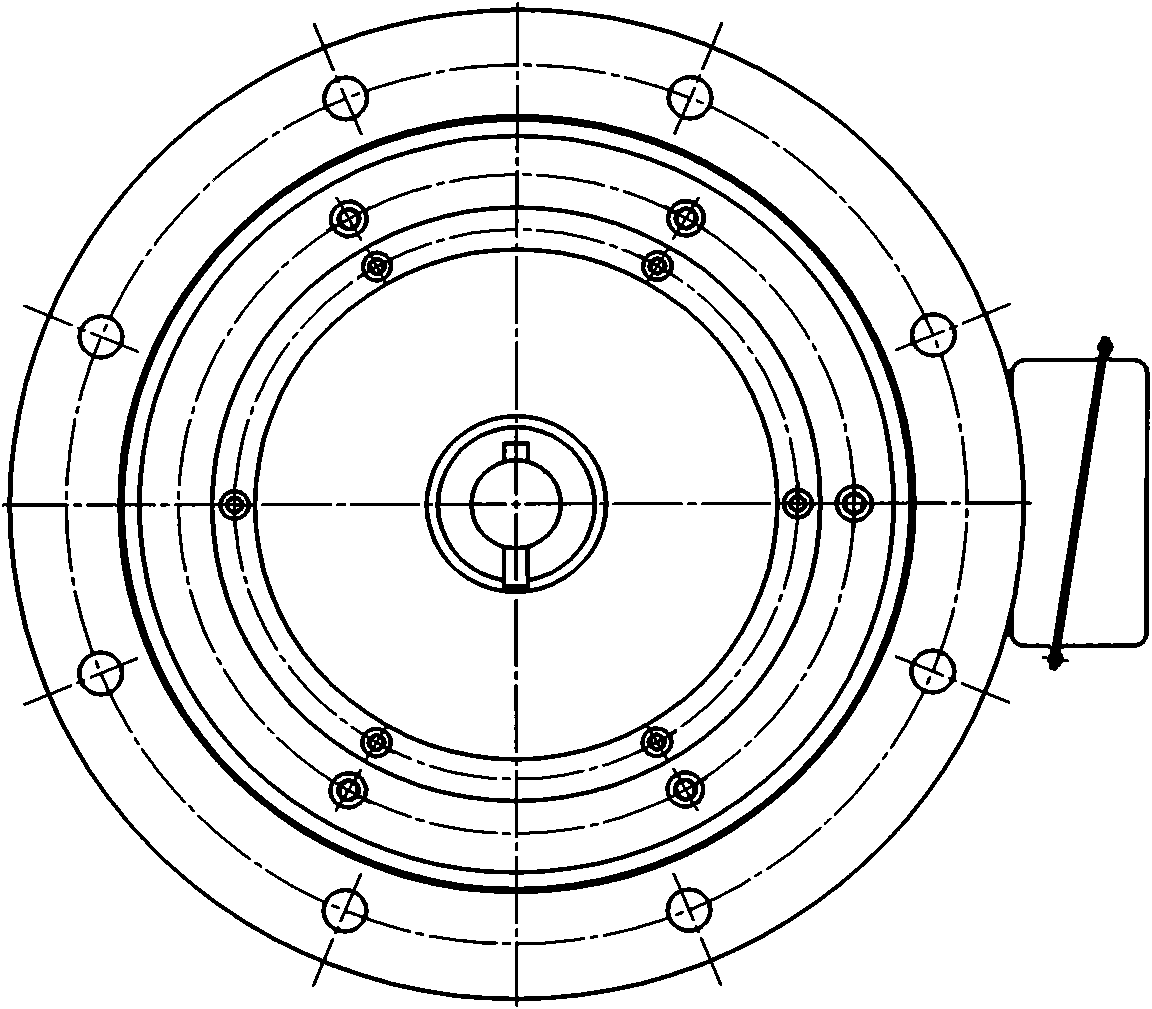

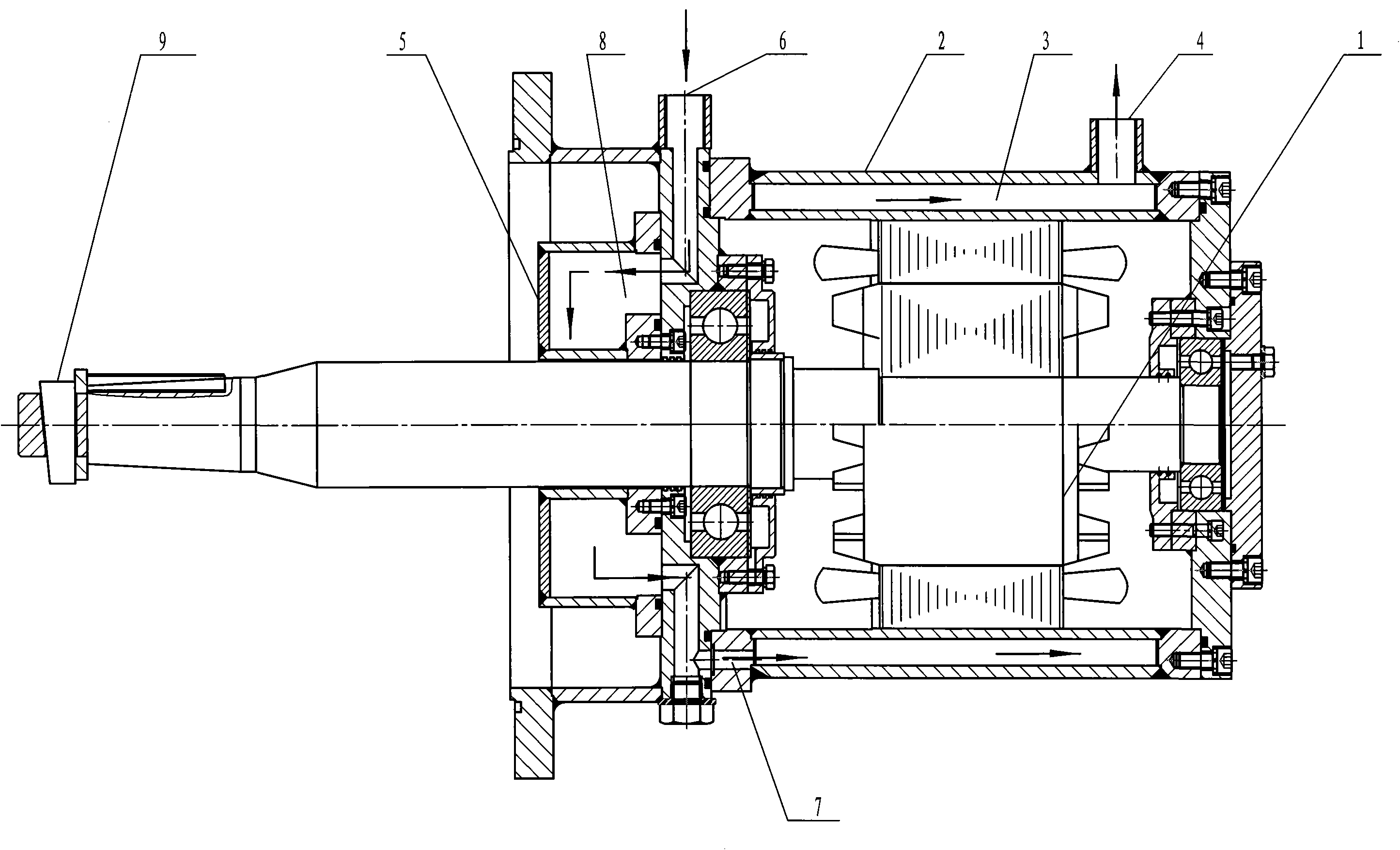

[0020] One-in-one-outlet double water-cooled sealed motor, its composition includes: motor 1, the housing 2 of the motor has a circulating water cavity 3, the circulating water cavity is connected to a water outlet 4, the housing of the motor The front is connected to the front end cover 5, and the inside of the front end cover has a cooling water cavity 8, and there is a water inlet 6 between the front end cover and the housing of the motor, and the water inlet is connected to the cooling water cavity, and the cooling water cavity is connected to the circulating water cavity through the internal water hole 7 .

Embodiment 2

[0022] In the one-inlet-one-outlet double water-cooled sealed motor described in Embodiment 1, a wedge key 9 is provided outside the shaft head of the motor.

[0023] This product is mainly used in a high temperature (1050°C) environment to stir and circulate the temperature and atmosphere in the heat treatment hot equipment, so that the temperature in the equipment can be kept uniform so that the heat treatment process can be carried out safely and efficiently.

[0024] Considering the high-temperature operating environment of the motor, special measures must be taken during the operation of the motor to reduce the temperature of the motor itself and keep the motor running continuously and safely. Therefore, the water cooling structure is adopted to reduce the high temperature during the use of the motor through water circulation. The water circulation through the front cover cools the front bearing and blocks the high temperature transmitted from the heat treatment equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com