Water-cooling rotary joint used for fan-shaped section drive roller of continuous casting machine

A continuous casting machine segment and rotary joint technology, which is applied in the field of water-cooled rotary joints, can solve the problems of insufficient cooling efficiency of driving rolls, short service life, broken foot rolls, etc., and reduce the possibility of dust or debris entering the bearings. The effect of improving the service life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

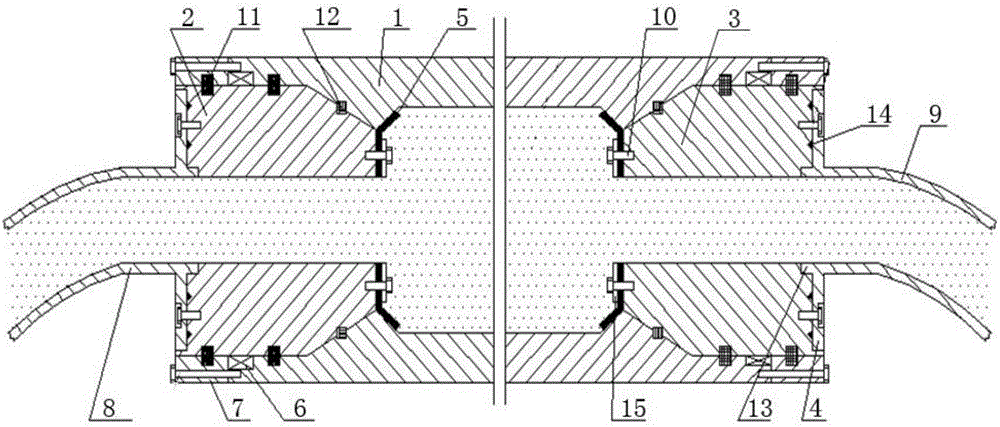

[0014] Such as figure 1 As shown in the figure, a water-cooled rotary joint used for driving rolls in continuous casting machine segments includes a roll sleeve 1, a left joint 2 and a right joint 3, the left and right joints both include an outer cylindrical section and an inner conical section, and the left and right joints It is symmetrically arranged on both sides of the roller sleeve and configured with the inner wall of the roller sleeve. The outer end faces of the left and right joints are connected to the positioning plate 4, and the inner end faces are connected to the flexible sealing plate 5. A bearing 6 is arranged between the outer cylindrical section and the inner wall of the roller sleeve, and The bearing end cover 7 is fixedly connected, the inner ring of the bearing is set on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com