Fiber-reinforced wet-laid/pre-laid waterproof membrane and its construction method

A waterproof membrane and fiber-reinforced technology, applied in chemical instruments and methods, infrastructure engineering, lamination, etc., can solve engineering leakage, entry into the structure, post-cast concrete and pre-laid polymer film membrane adhesive The failure of layer bonding and sealing performance, etc., achieves the effects of strong weather resistance, preventing wrinkles, and good contact with the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

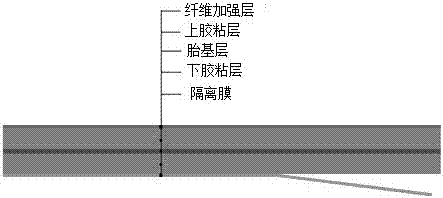

[0055] Such as figure 1 and figure 2 As shown, the fiber-reinforced wet-laid / pre-laid waterproof membrane consists of a fiber-reinforced layer, an upper adhesive layer, a base layer, a lower adhesive layer and an isolation membrane.

[0056] Among them, the fiber reinforcement layer is made of polyester non-woven fabric, and its specification is 60g / m 2 The base layer is made of PET ester film with a thickness of 0.05mm and a tensile force of 200N / 5cm; the thickness of the upper adhesive layer and the lower adhesive layer are both 0.7mm; the isolation film is made of PE film.

[0057] The thickness of the waterproof membrane is 1.5mm; the length is 20m, and the width is 1.0m.

[0058] The adhesive layer is modified asphalt: the modifier is SBS.

[0059] The production method of the waterproof membrane is mainly divided into the following steps:

[0060] 1. Place the base layer and the isolation film in sequence, add adhesive between the two, and press the "sandwich" struc...

Embodiment 2

[0073] The fiber-reinforced wet-laid / pre-laid waterproof membrane consists of a fiber-reinforced layer, an upper adhesive layer, a base layer, a lower adhesive layer and an isolation membrane.

[0074] Among them, the fiber reinforced layer is made of polypropylene non-woven fabric, and its specification is 100g / m 2 The base layer of the tire is made of TPO film with a thickness of 0.30mm and a tensile force of 500N / 5cm; the thickness of the upper adhesive layer and the lower adhesive layer are both 0.82mm; the isolation film is made of PE film.

[0075] The thickness of the waterproof membrane is 2.0mm; the length is 15m, and the width is 1m.

[0076] The adhesive layer is modified asphalt: the modifier is SBR.

[0077] The production method of the waterproof membrane is mainly divided into the following steps:

[0078] 1. Place the base layer and the isolation film in sequence, add adhesive between the two, and press the "sandwich" structure together with the pair of rolle...

Embodiment 3

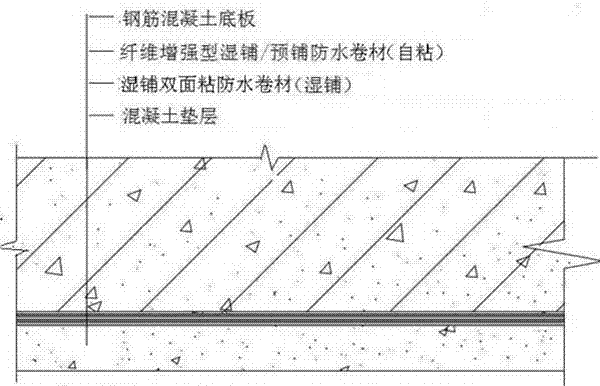

[0091] Such as figure 1 and image 3 As shown, the fiber-reinforced wet-laid / pre-laid waterproof membrane consists of a fiber-reinforced layer, an upper adhesive layer, a base layer, a lower adhesive layer and an isolation membrane.

[0092] Among them, the fiber reinforced layer is made of polyester fiber non-woven fabric, and its specification is 70g / m 2 The tire base layer is made of PE film with a thickness of 0.10mm and a tensile force of 200N / 5cm; the thickness of the upper adhesive layer and the lower adhesive layer are both 0.68mm; the isolation film is made of PP film.

[0093] The thickness of the waterproof membrane is 1.5mm; the length is 20m, and the width is 1m.

[0094] The adhesive layer is modified asphalt: the modifier is APP.

[0095] The production method of the waterproof membrane is mainly divided into the following steps:

[0096] 1. Place the base layer and the isolation film in sequence, add adhesive between the two, and press the "sandwich" struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com