An insulation system facing structure

A technology of thermal insulation system and veneer, applied in thermal insulation, building structure, building components, etc., can solve the problem of high cost, and achieve the effect of reducing use, reducing cost and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the present invention's bottoming decorative putty is:

[0032] Weigh each component of the primer decorative putty by weight percentage, put 200 mesh quartz sand, cellulose ether, waste paper fiber, sodium polyacrylate, active material and pigment into a high-speed mixing machine with a speed of 1300r / min and a volume of 200L Mix in the machine for 3 minutes to prepare the mixture, release it for later use; put the aluminate cement, acrylic acid redispersible latex powder, filler, zeolite powder and the mixture into the mortar mixer, add water and mix for 3 minutes to obtain the base decorative putty.

[0033] See Table 1 with the performance of the primer putty prepared by the present invention:

[0034] Table 1: The performance index of the primer putty prepared by the present invention

[0035]

[0036] The above experiments refer to the following standards: "Flexible Putty for Exterior Walls" (GB / T 23455-2009), "Primers for Building In...

Embodiment 1

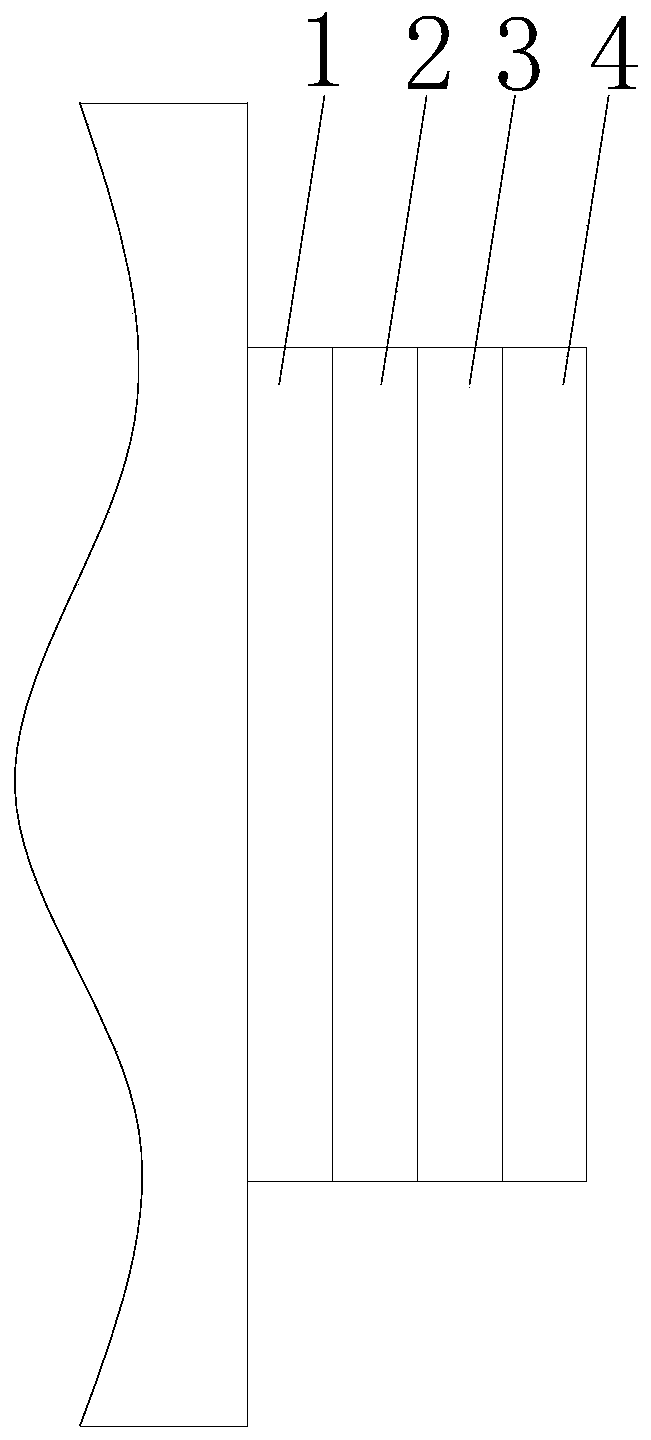

[0038] The present invention provides a facing structure of the heat preservation system, the facing structure is an insulating layer, an anti-cracking layer, a putty layer, and a finishing paint layer in order from the inside to the outside; wherein:

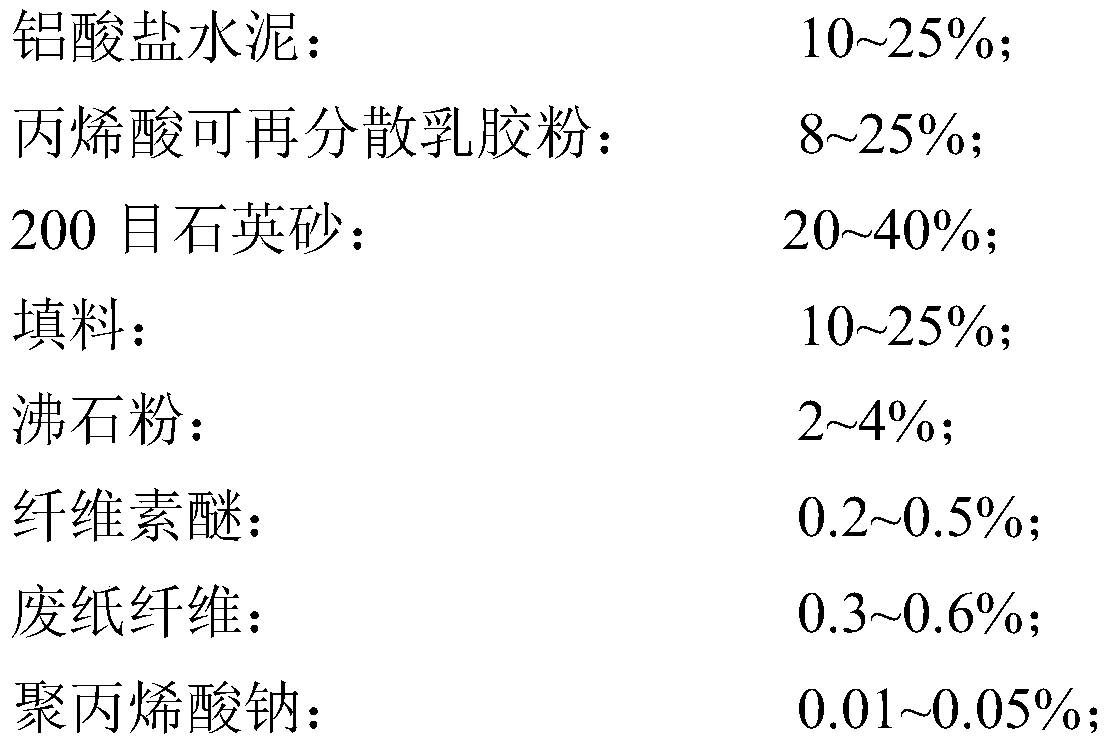

[0039] The putty layer is a layered structure formed by stirring and mixing the primer decorative putty with water and applying it on the anti-crack layer; by weight percentage, the primer decorative putty contains the following components:

[0040]

[0041] in:

[0042] The filler is a mixture of 600 mesh heavy calcium and 200 mesh wollastonite powder, and the weight ratio of 600 mesh heavy calcium to 200 mesh wollastonite powder is 2:1;

[0043] The pigment is one or a mixture of titanium dioxide and iron oxide pigments, and the appropriate ratio of titanium dioxide and iron oxide pigments is selected according to the color of the putty required.

Embodiment 2

[0045] The present invention provides a facing structure of the heat preservation system, the facing structure is an insulating layer, an anti-cracking layer, a putty layer, and a finishing paint layer in order from the inside to the outside; wherein:

[0046] The putty layer is a layered structure formed by stirring and mixing the primer decorative putty with water and applying it on the anti-crack layer; by weight percentage, the primer decorative putty contains the following components:

[0047]

[0048] in:

[0049] The filler is a mixture of 600 mesh heavy calcium and 200 mesh wollastonite powder, and the weight ratio of 600 mesh heavy calcium to 200 mesh wollastonite powder is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com