Fiber reinforced TSR polyethylene tire modified asphalt waterproofing coil and construction method thereof

A polyethylene tire, modified asphalt technology, applied in the direction of adhesive type, infrastructure engineering, film/sheet adhesive, etc. It can improve the impact damage resistance, reduce the leakage rate, and improve the corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

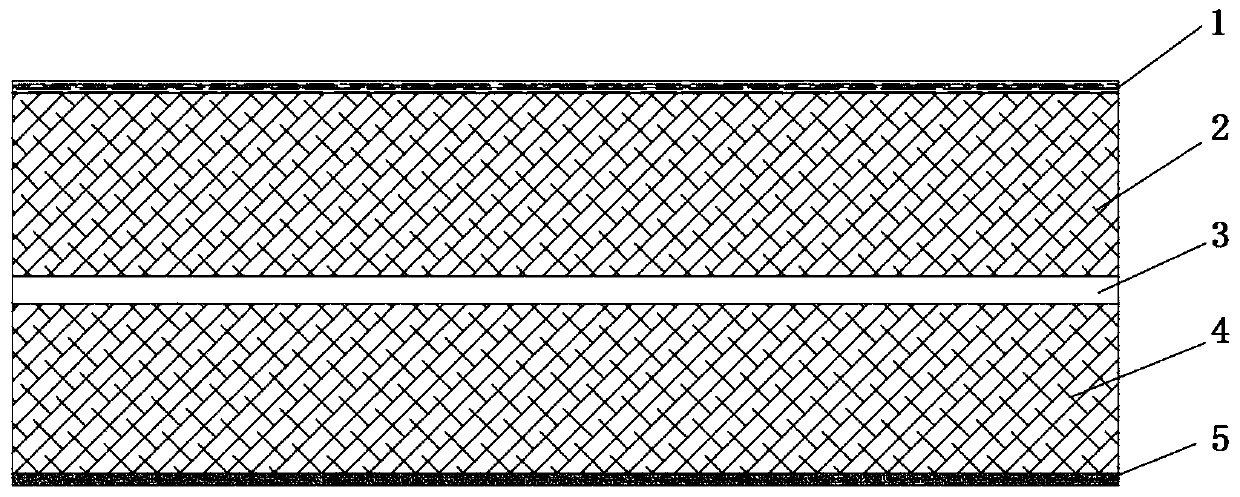

[0036] Such as figure 1 As shown, a fiber-reinforced TSR polyethylene tire modified asphalt waterproof membrane includes a fiber reinforced layer 1, an upper adhesive layer 2, a modified polyethylene tire base layer 3, a lower adhesive layer 4 and Isolation film5.

[0037] Wherein, the fiber-reinforced layer 1 is one of non-woven fabrics made of polyester, polypropylene, polyester fiber, nylon or polypropylene fiber.

[0038] Wherein, the upper adhesive layer 2 and the lower adhesive layer 4 are both chemical root puncture resistant colloidal layers.

[0039] Wherein, the preparation method of the chemical root-resistant puncture-resistant colloidal layer is as follows:

[0040] S1: ratio of asphalt and oil;

[0041] S2: Add polymer modifier SBS, butyl rubber IIR and natural rubber CR, keep the temperature at 180-190 degrees Celsius, and stir at 45Hz for 1 hour;

[0042] S3: Grinding with a colloid mill at a grinding temperature of 180-190 degrees Celsius;

[0043] S4: ke...

Embodiment 2

[0047] The invention also discloses a construction method of fiber-reinforced TSR polyethylene tire modified asphalt waterproofing membrane, which includes the following steps:

[0048] P1: Concrete cushion construction on the floor of the underground project, leveled and calendered once; the thickness of the concrete cushion is 100-150mm.

[0049] P2: Hot-melt construction: After the surface of the cushion concrete is flat, dry, and free of open water, the hot-melt fiber-reinforced TSR polyethylene tire modified asphalt waterproofing membrane makes the fiber-reinforced TSR polyethylene tire modified asphalt waterproofing membrane The material is bonded to the cushion concrete and the cushion concrete is sealed so that the fiber reinforced layer faces upward;

[0050] P3: Pre-paving construction: After 12-24 hours, on the surface of the waterproof layer, on the surface of the completed waterproof layer, the reinforcement of the base plate structure is plated on the fiber reinf...

Embodiment 3

[0054] In TSR, T is a hot-melt type, S is a self-adhesive type, and R is a polymer-modified asphalt root-resistant waterproof membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com