High performance room temperature cured titanium boride cathode coating for aluminium reduction cell

A technology of curing aluminum electrolytic cells at room temperature, applied in the field of cathode coatings for aluminum electrolytic cells, to achieve the effects of improving impact damage resistance, small deformation, and accelerating heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The formula of the titanium boride cathode coating paste of this embodiment is shown in Table 1.

[0039] Table 1

[0040]

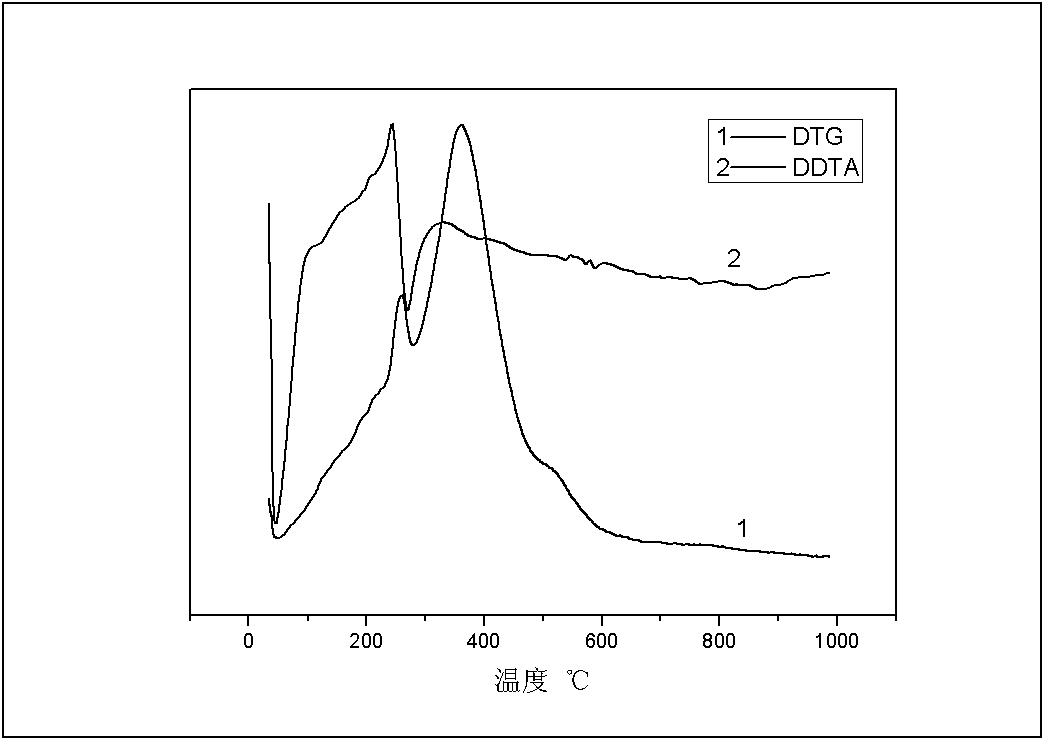

[0041] Stir and mix the materials in Table 1 to form a paste, then apply it on the carbon cathode of the aluminum electrolytic cell, and cure it at room temperature for 24 hours. At the same time, the coating paste sample was taken for comprehensive thermal analysis, and the results were as follows: figure 1 shown. according to figure 1 According to the comprehensive thermal analysis results, according to the method for determining the carbonization temperature rise system in the summary of the invention, the specific carbonization variable speed temperature rise system of the coating paste is determined, as shown in Table 2. In practical applications, high-temperature carbonization can be carried out by using the heat generated by the aluminum electrolytic roasting process according to the carbonization variable speed heating system given i...

Embodiment 2

[0046] The formula of the titanium boride cathode coating paste of this embodiment is shown in Table 3.

[0047] table 3

[0048]

[0049] The construction method of this embodiment and the determination of the carbonization variable speed heating system of the cathode coating are the same as that of Embodiment 1, omitted. TiB obtained after high temperature carbonization 2 Cathode coating, no cracks, no falling off, the bonding strength is greater than the tensile strength of the semi-graphite cathode carbon block for aluminum electrolysis (>3.0MPa); the resistivity at 25°C: 26.6μΩ·m; wet with aluminum liquid It has good performance and has the basic conditions for application in aluminum electrolysis production.

[0050] In addition, the cross-sectional morphology of the titanium boride cathode coating prepared in this example is shown in image 3 . It can be seen from the figure that TiB 2 Uniformly dispersed in the coating, while the carbon fiber is embedded betwee...

Embodiment 3

[0052] The formula of the titanium boride cathode coating paste of this embodiment is shown in Table 4.

[0053] Table 4

[0054]

[0055] The construction method of this embodiment and the determination of the carbonization variable speed heating system of the cathode coating are the same as that of Embodiment 1, omitted. TiB obtained after high temperature carbonization 2 Cathode coating, no cracks, no falling off, bonding strength greater than the tensile strength of semi-graphite cathode carbon block for aluminum electrolysis (>3.0MPa); open porosity <13%; resistivity at 25°C: 31.4μΩ· m; It has good wettability with molten aluminum and has the basic conditions for application in aluminum electrolysis production.

[0056] In addition, the cross-sectional morphology of the titanium boride cathode coating prepared in this example is shown in Figure 4 . It can be seen from the figure that TiB 2 Uniformly dispersed in the coating, while the carbon fiber is embedded bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com