Cooling system for crystal used by laser

A cooling system and laser technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of easy condensation and poor heat insulation of the device, increase thermal conductivity, reduce thermal lens effect, and ensure normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

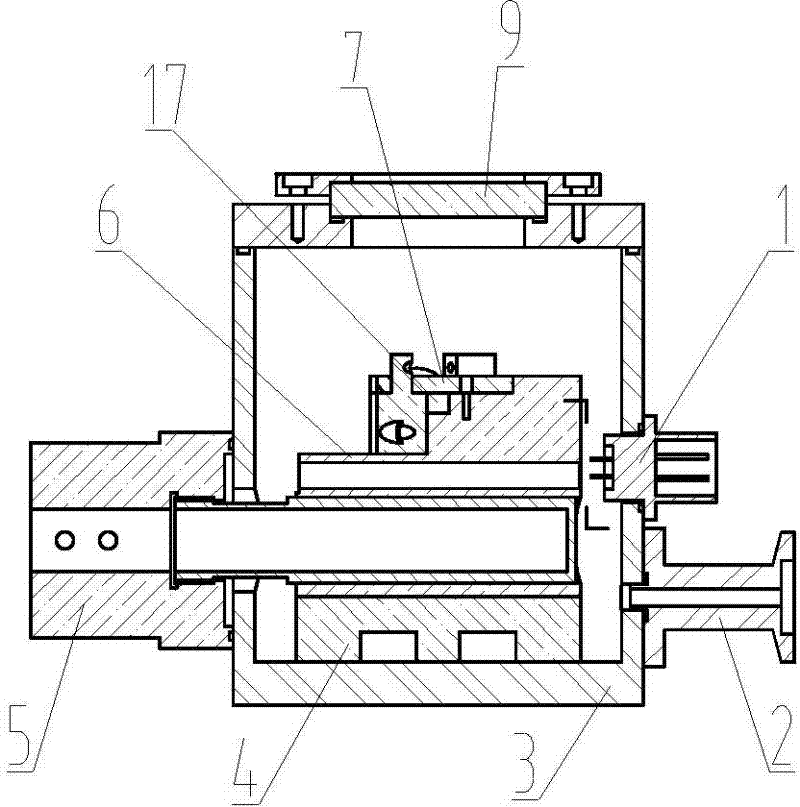

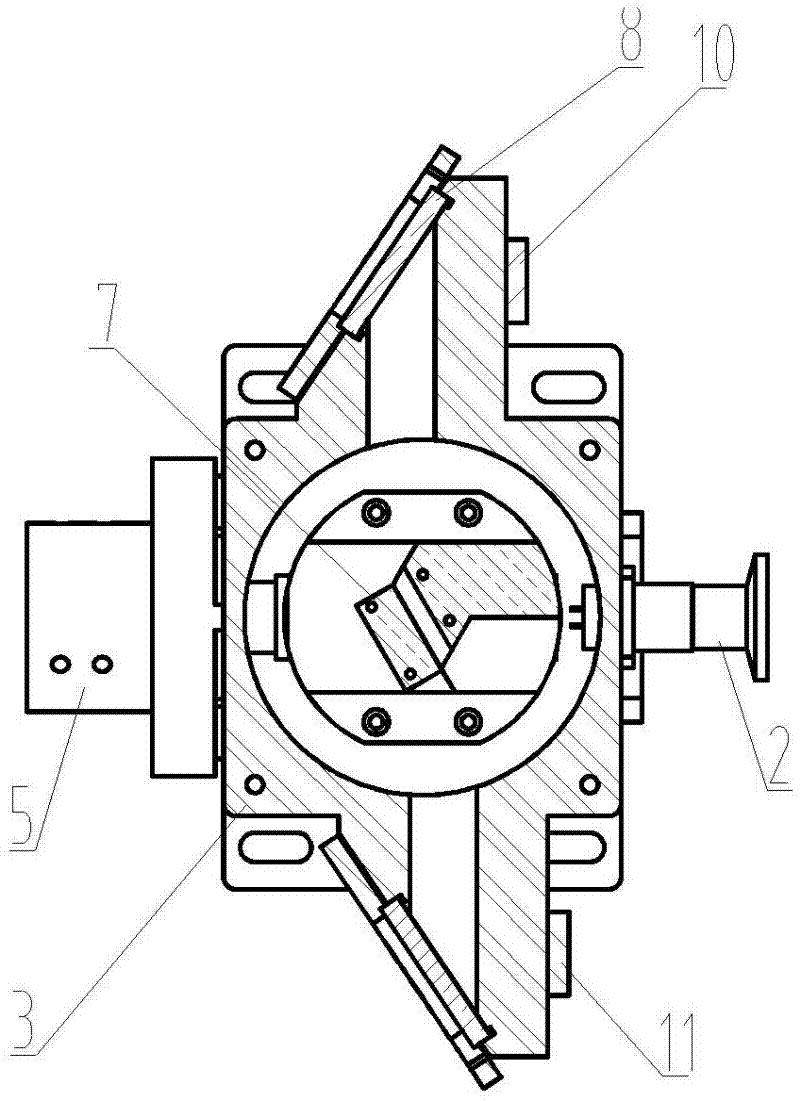

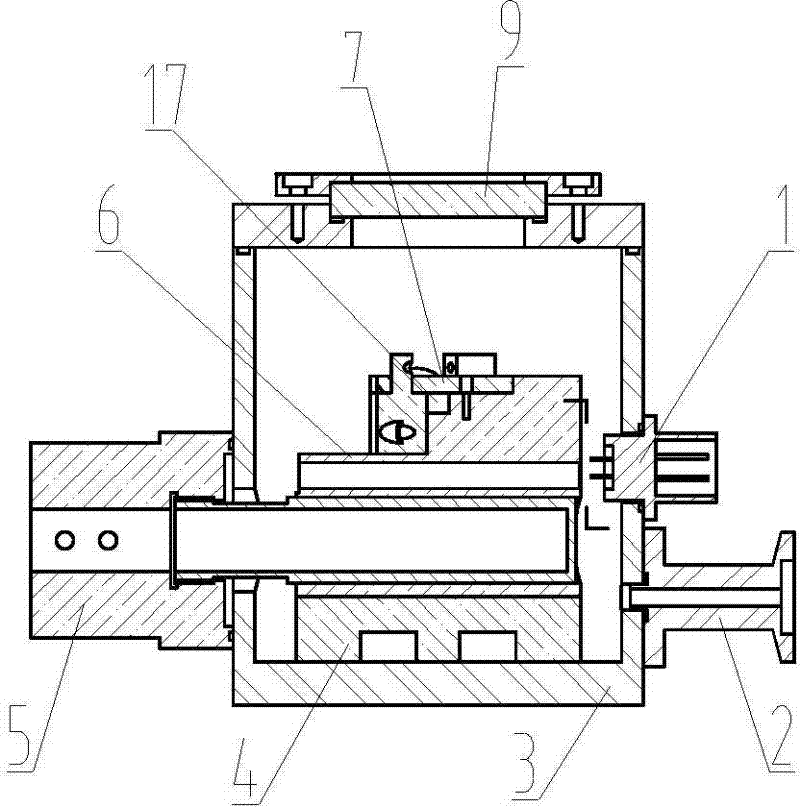

[0028] figure 1 It is a front view of a cooling system for a laser crystal of the present invention, figure 2 for figure 1 Sectional view on plane A-A in . exist figure 1 , figure 2 A cooling system for crystals used in lasers according to the present invention includes a crystal heat sink device, a temperature measuring device interface 1, a vacuum device interface 2, a vacuum chamber 3, a cooling interface device 5, a Brewster window 8, and an observation window 9; The crystal heat sink device includes a crystal heat sink 6, an inner and outer heat insulating pad 4, a crystal 17 and a crystal heat sink gland 7, wherein the crystal heat sink 6 is fixedly connected with the inner and outer heat insulating pad 4, and the crystal heat sink 6 is equipped with The crystal 17, the crystal heat sink gland 7 compresses the crystal 17 and is fixedly arranged on the crystal heat sink 6, and a through hole is arranged in the crystal heat sink 6; the vacuum chamber 3 is a cylindric...

Embodiment 2

[0040] In the present embodiment, the basic structure of the cooling system of a kind of laser crystal of the present invention is the same as that of Embodiment 1, the difference is,

[0041] In this embodiment, the inner and outer heat insulating pads 4 are made of heat insulating materials with a thermal conductivity of 0.08 W / (m·K).

[0042] The thickness of the inner and outer thermal insulation pads 4 is 15mm.

[0043] The heat conduction metal tube in the cooling device interface 5 has a thermal conductivity of 450W / (m·K), and the heat insulating seat is made of a heat insulating material with a thermal conductivity of 0.08W / (m·K).

[0044] The outer diameter of the heat-conducting metal tube in the cooling interface device 5 and the roughness of the through hole corresponding to the crystal heat sink 6 are both 0.8, and the gap is 0.01mm;

[0045] The unilateral gap between the outer diameter of the heat-conducting metal tube in the cooling interface device 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com