High-heat conductivity composite material for LED (light-emitting diode) lamp, heat-conducting filler and production equipment

A technology of thermally conductive fillers and composite materials, which is applied in the field of thermally conductive fillers and production equipment, and high thermally conductive composite materials. The effect of small temperature difference between inside and outside, high shear strength and good packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of the modified thermally conductive filler is realized by the following steps:

[0078] 1) Prepare water-acetone solution, the mass ratio of water: acetone is 5-10:90-95;

[0079] 2) Dissolving the surface coupling agent in water-acetone solution to prepare a coupling agent-water-acetone solution with a concentration of titanium-based coupling agent of 10-25wt.%.

[0080] 3) Using a high-speed mixer with heating function, use the spray method to add the coupling agent-water-acetone solution to the thermally conductive filler. 300 mix. Specific steps: divide the prepared coupling agent-water-acetone solution into 5 to 10 times of spraying, and stir the thermal conductive filler at high speed for 10 to 20 minutes after each spraying, and the stirring speed of the mixer is 1200 to 2000 rpm. The stirring temperature is 80-120° C., so as to obtain the modified heat-conducting filler.

[0081] The present invention also includes a device for prepari...

Embodiment 5

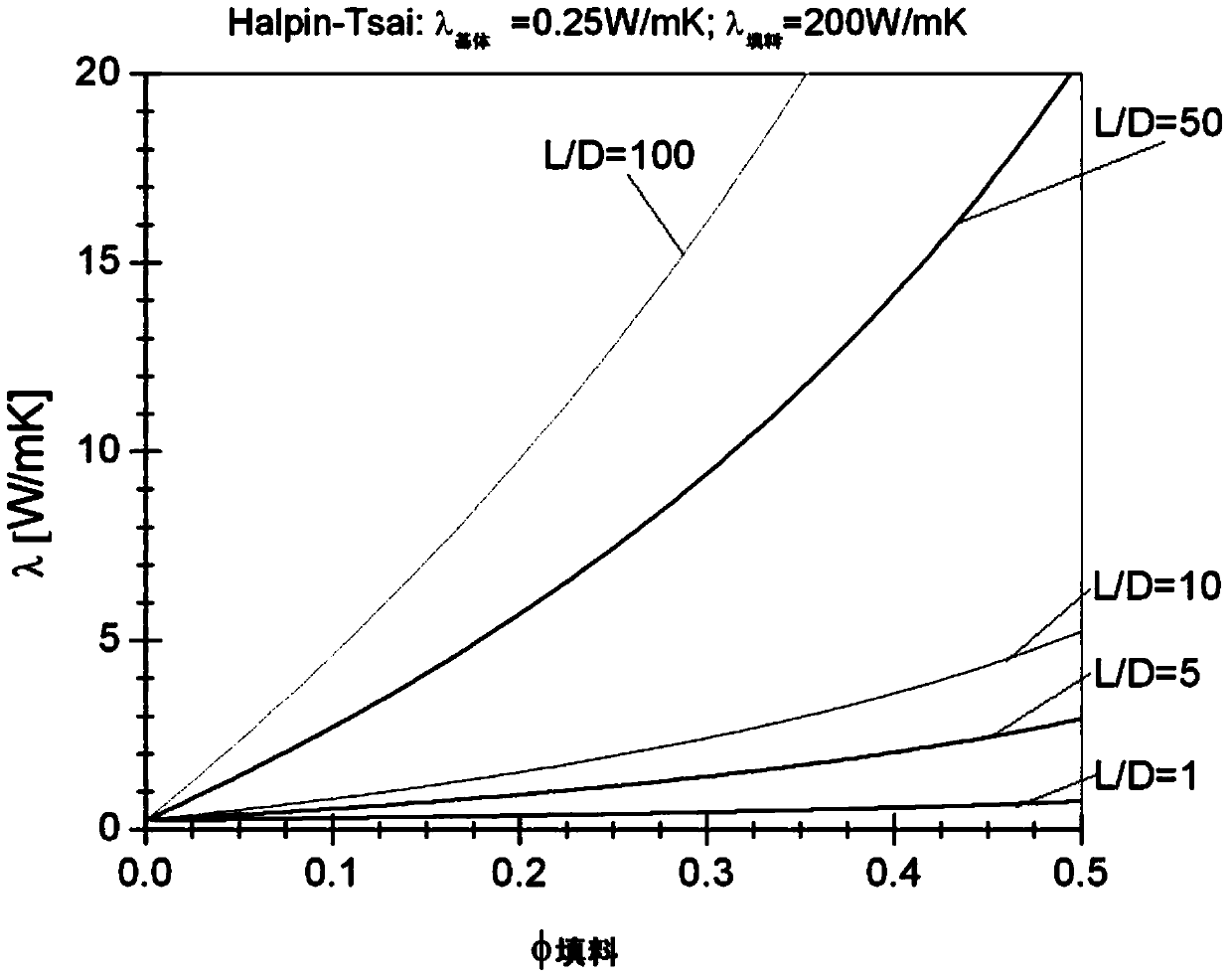

[0102] 3) Example 4, when the content of modified silicon carbide reaches 35%, the thermal conductivity λ of the PA6 composite material system has reached 11.2, which belongs to the convection limitation mechanism, that is, the temperature passing through the polymer material plate is uniform, and only Restricted by the convection process, the mechanical properties are good, meeting the heat dissipation performance requirements of LED lamps, and the overall performance is better than that of Example 5;

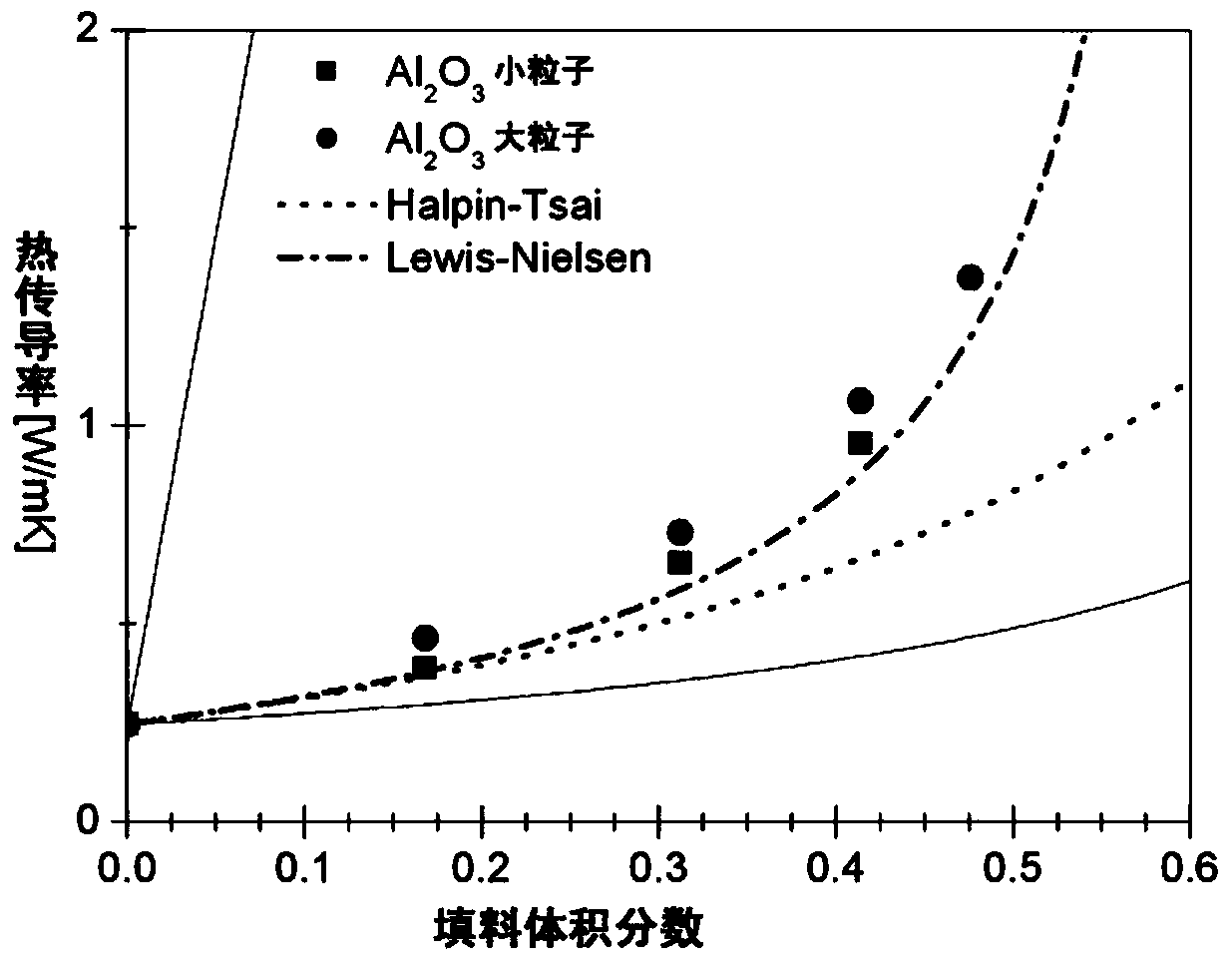

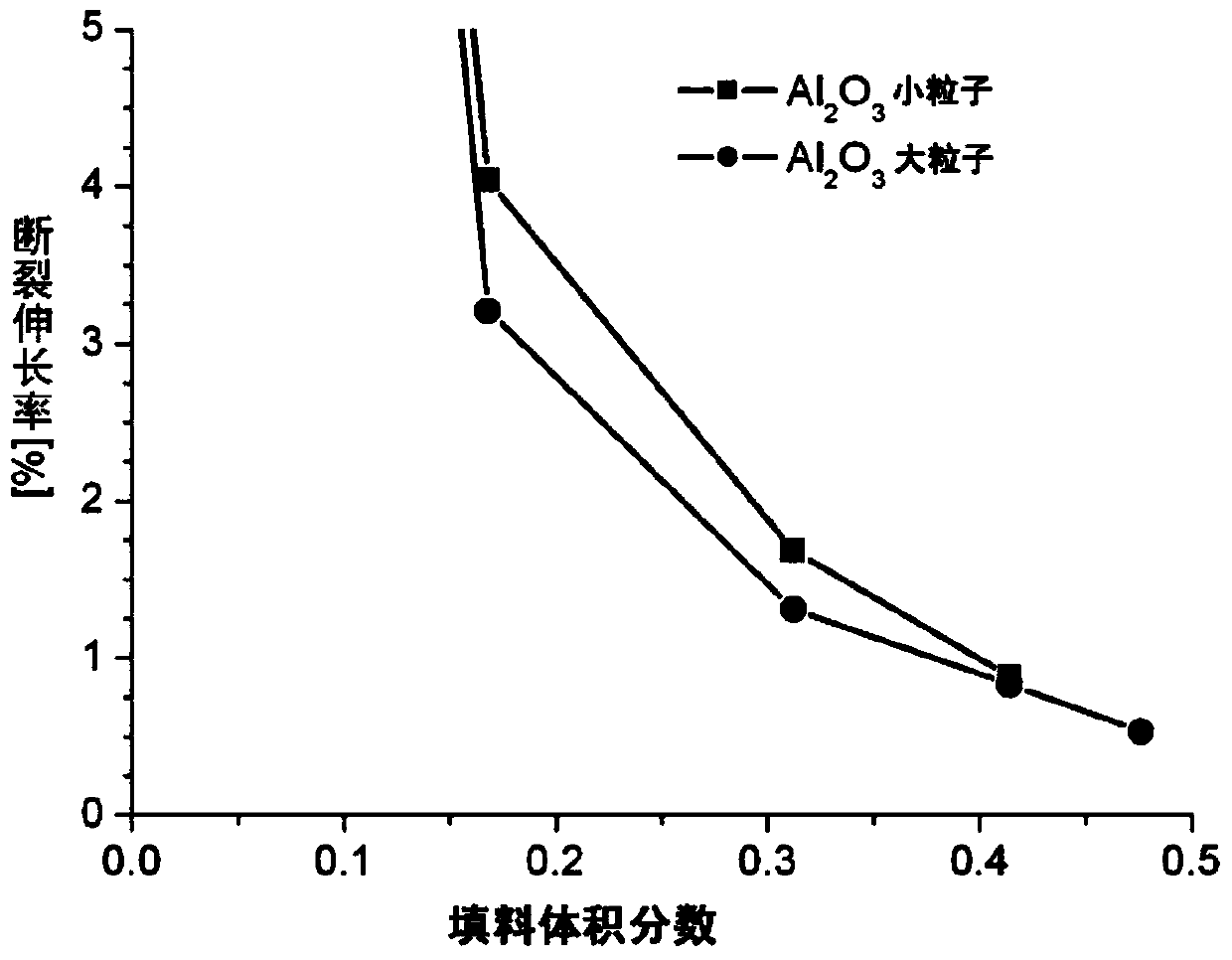

[0103] 4) In comparative example 1, although 35% of alumina has been added, the thermal conductivity λ of the PA6 composite system can only reach 0.6. The reason is that the aspect ratio of alumina is too small (L / D≈1), although It is close to the random close packing threshold (RCPT), but it is difficult to form a thermal network chain, the thermal resistance between particles is too large, and the mechanical properties are poor, which cannot meet the heat dissipation performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com