Q460E steel plate with thickness larger than 120 mm and manufacturing method of steel plate

A technology of steel plate and grain size, applied in the field of extra-thick Q460E steel plate and its manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

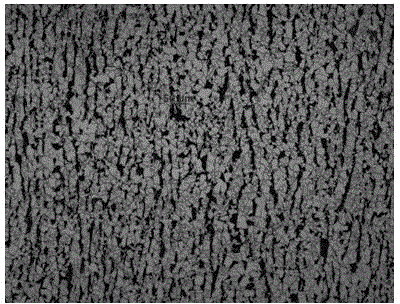

Image

Examples

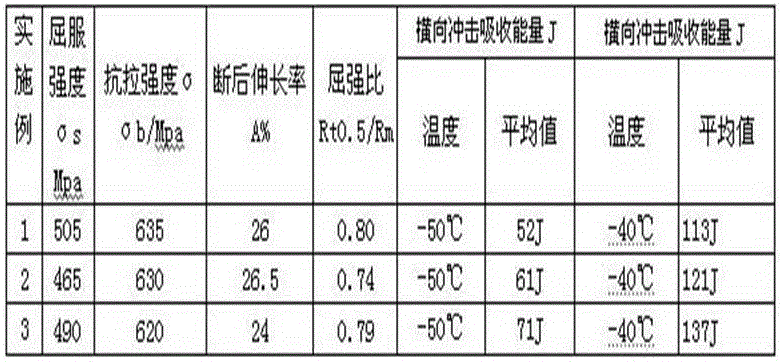

Embodiment 1

[0027] The thickness of the Q460E steel plate in this embodiment is 120 mm, and its chemical composition is calculated by mass percentage: C: 0.15%, Mn: 1.75%, Si: 0.4%, S: 0.01%, P: 0.015%, Nb: 0.045%, Ti: 0.018%, V: 0.08%, Al: 0.030%, N: ≤ 0.010%, O: ≤ 0.006%, Mo: ≤ 0.15%, Cu: 0.30%, Ni: 0.20%, Cr≤ 0.15%, Ca: 0.001%, the balance is Fe and unavoidable impurity elements.

[0028]The manufacturing process of the 120mm thick Q460E steel plate is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then go through KR molten iron pretreatment, converter smelting, LF refining, RH vacuum refining and continuous casting in sequence to produce a product that meets the chemical composition requirements, A continuous casting slab with a thickness of about 350mm. Reheat the continuous casting slab to 1235°C and keep it warm for 7 hours; after it comes out of the furnace, carry out two-stage rolling: the first stag...

Embodiment 2

[0031] The thickness of the Q460E steel plate in this embodiment is 125mm, and its chemical composition is calculated by mass percentage: C: 0.19%, Mn: 1.55%, Si: 0.20%, S: 0.008%, P: 0.01%, Nb: 0.05%, Ti: 0.018%, V: 0.10%, Al: 0.035%, N: ≤ 0.010%, O: ≤ 0.006%, Mo: ≤ 0.15%, Cu: 0.35%, Ni: 0.20%, Cr≤ 0.15%, Ca: 0.001%, the balance is Fe and unavoidable impurity elements.

[0032] The manufacturing process of the 125mm thick Q460E steel plate is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then go through KR molten iron pretreatment, converter smelting, LF refining, RH vacuum refining and continuous casting in sequence to produce a product that meets the chemical composition requirements, A continuous casting slab with a thickness of 370mm. Reheat the continuous casting slab to 1225°C and keep it warm for 8 hours; after it comes out of the furnace, carry out two-stage rolling: the first stage is r...

Embodiment 3

[0035] The thickness of the Q460E steel plate in this embodiment is 130 mm, and its chemical composition is calculated by mass percentage: C: 0.17%, Mn: 1.65%, Si: 0.20%, S: 0.005%, P: 0.01%, Nb: 0.04%, Ti: 0.018%, V: 0.14%, Al: 0.030%, N: ≤ 0.010%, O: ≤ 0.006%, Mo: ≤ 0.15%, Cu: 0.25%, Ni: 0.20%, Cr≤ 0.15%, Ca: 0.001%, the balance is Fe and unavoidable impurity elements.

[0036] The manufacturing process of the 130mm thick Q460E steel plate is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then go through KR molten iron pretreatment, converter smelting, LF refining, RH vacuum refining and continuous casting in sequence to produce a product that meets the chemical composition requirements, A continuous casting slab with a thickness of 370mm. Reheat the continuous casting slab to 1240°C and keep it warm for 7 hours; after it comes out of the furnace, carry out two-stage rolling: the first stage is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com