Tunnel lining concrete heat preserving and maintaining construction device

A technology of lining concrete, heat preservation and maintenance, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the health problems of construction workers, avoid quality problems, prevent frost heave, and reduce the effect of internal and external temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

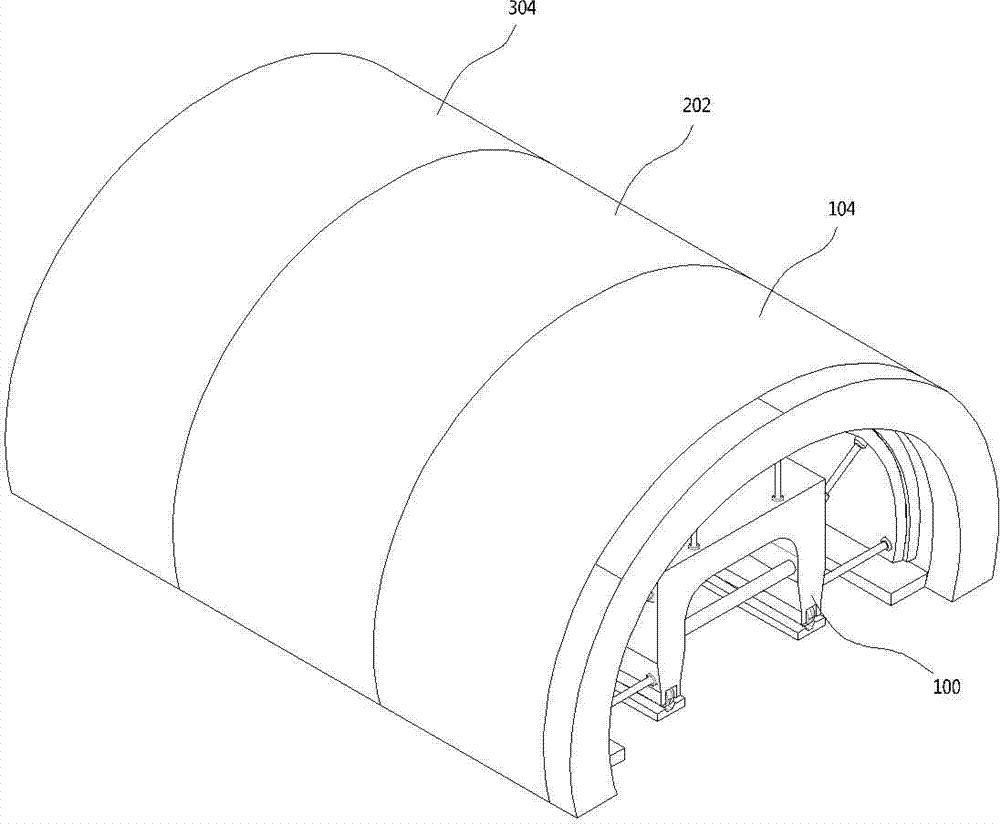

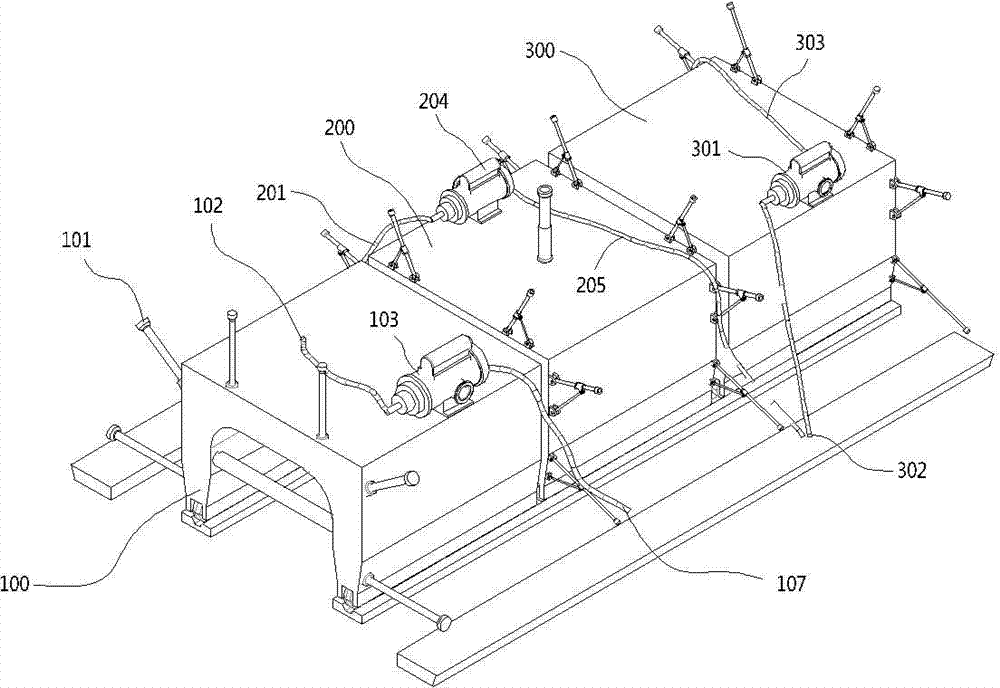

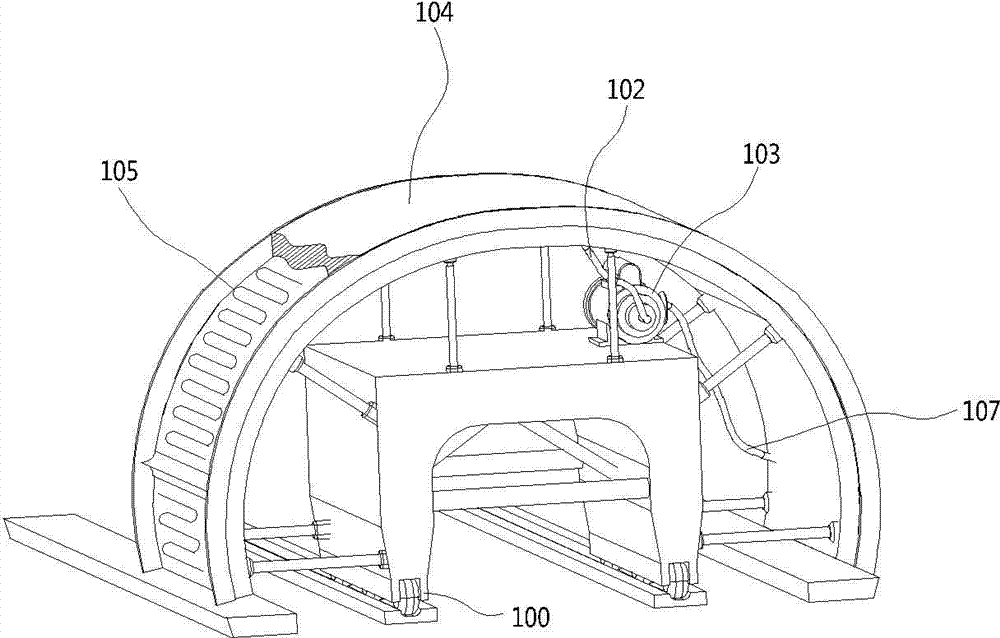

[0025] As shown in the figure, a tunnel lining concrete insulation maintenance construction device includes a first trolley 100, a second trolley 200 and a third trolley 300 connected in sequence. In addition, the first trolley 100, the second trolley The movable and dismountable connection modes adopted by the cart 200 and the third trolley 300 have different functions. Therefore, the three types of trolleys can also be used in pairs according to construction requirements, such as the first trolley 100 and the second trolley 200 or the second trolley 200 and the third trolley 300 or the first trolley 100 and The third car is 300. Simultaneously, also can carry out construction work independently, all are provided with the formwork supported by support bar 101 on three trolleys. Both ends of the templates of the first trolley 100 , the second trolley 200 and the third trolley 300 are provided with heat insulating layers, and the heat insulating layers are foam material heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com