Rural waste cement concrete road renovated pavement structure and filling method thereof

A cement concrete and pavement structure technology, applied to drainage structures, roads, roads, etc., can solve the problems of shortening the service life of the reconstructed pavement, increasing the purchase cost, and water seepage of the pavement, so as to increase farmers' income, slow down fatigue cracking, and prevent frost heave Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

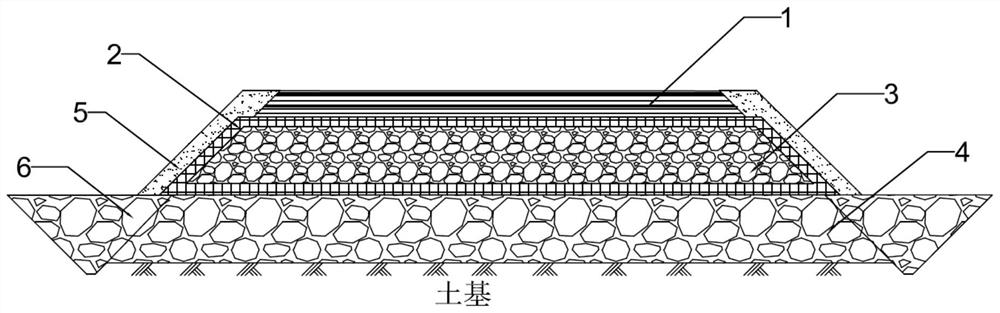

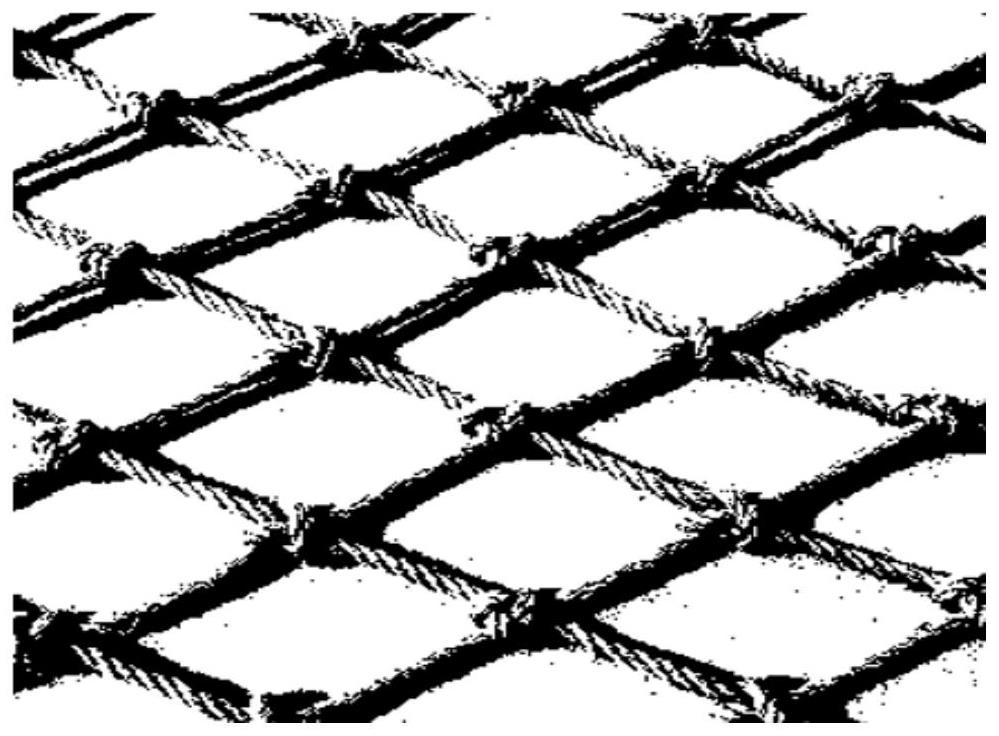

[0026] The pavement structure for renovating rural waste cement concrete roads, the pavement structure includes an asphalt surface layer 1, a graded crushed stone layer 3 and a recycled crushed stone layer 4 arranged from top to bottom above the soil foundation; both sides of the recycled crushed stone layer 4 A V-shaped recycled gravel drainage ditch 6 is opened, and the ditch is filled with recycled gravel; road shoulders 5 are provided on both sides of the pavement structure extending from the asphalt surface layer 1 to the recycled gravel drainage ditch 6; the graded gravel layer 3 is surrounded by plant fiber grids Grid 2.

[0027] The maximum particle size of the regenerated gravel in the regenerated gravel layer 4 is 40mm, wherein the gravel with a particle size of less than 5mm accounts for 25%-30%, and the gravel with a particle size of 5mm-10mm accounts for 25%-30%. 10mm-20mm crushed stones account for 25%-35%, 20mm-30mm crushed stones account for 10%-20%, and 30mm-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com