An anti-seepage and anti-freeze concrete pole

A technology of concrete and electric poles, applied in towers, building types, buildings, etc., can solve the problems of low strength, poor frost resistance, seepage resistance and corrosion resistance, and achieve high strength, excellent frost crack resistance and corrosion resistance, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

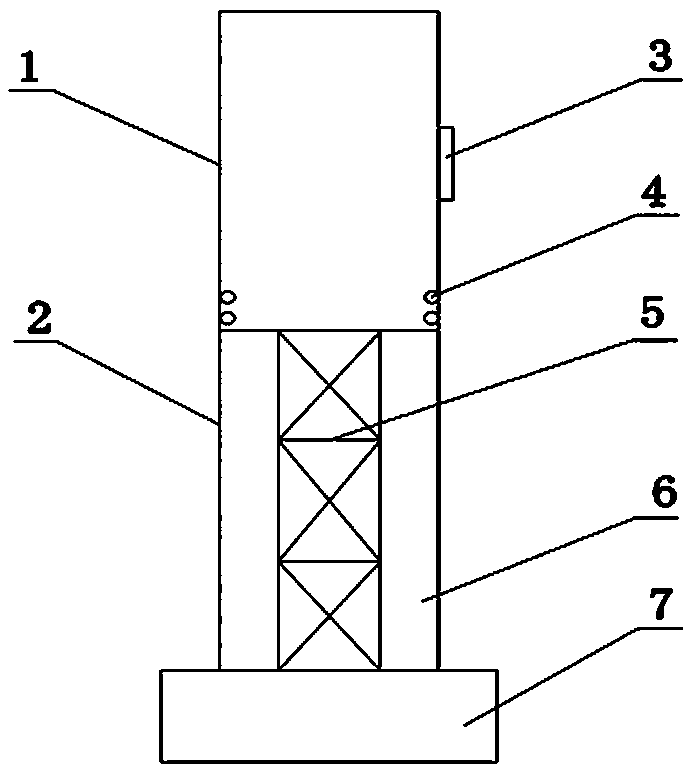

[0029] Such as figure 1 As shown, a kind of anti-seepage and antifreeze concrete electric pole, described electric pole comprises upper and lower two parts, is respectively hollow pole 1 and solid pole 2, and the top of described hollow pole 1 is sealing structure, and the middle part of described hollow pole 1 A safety mark 3 is provided; the hollow rod 1 is a concrete hollow structure, which is connected to the solid rod 2 through a connecting piece, and several reserved holes 4 are set in the lower part of the hollow rod 1 to ensure that the water entering the pole Discharge in time; the solid rod 2 is composed of a steel bar skeleton 5 and a concrete layer 6 wrapping the steel bar skeleton 5, the bottom of the solid bar 2 is provided with a steel plate end 7, and the steel plate end 7 is fixed on the solid bar through a steel wire connection 2 on.

[0030] The anti-seepage and anti-freeze concrete poles are prepared according to the following process:

[0031] 1) Take va...

Embodiment 2

[0037] Such as figure 1 As shown, a kind of anti-seepage and antifreeze concrete electric pole, described electric pole comprises upper and lower two parts, is respectively hollow pole 1 and solid pole 2, and the top of described hollow pole 1 is sealing structure, and the middle part of described hollow pole 1 A safety mark 3 is provided; the hollow rod 1 is a concrete hollow structure, which is connected to the solid rod 2 through a connecting piece, and several reserved holes 4 are set in the lower part of the hollow rod 1 to ensure that the water entering the pole Discharge in time; the solid rod 2 is composed of a steel bar skeleton 5 and a concrete layer 6 wrapping the steel bar skeleton 5, the bottom of the solid bar 2 is provided with a steel plate end 7, and the steel plate end 7 is fixed on the solid bar through a steel wire connection 2 on.

[0038] The anti-seepage and anti-freeze concrete poles are prepared according to the following process:

[0039] Take each ...

Embodiment 3

[0045] Taking the common cement concrete electric pole commonly used in the market as a control group, the various aspects of performance of the electric pole of the present invention have been detected. Taking Example 2 as an example, see Table 1 for details:

[0046] Table 1

[0047] performance

[0048] Conclusion: Compared with the cement concrete poles commonly used in the market, the electric poles of the present invention have higher flexural and compressive strength, good carbonation resistance, similar impermeability and freeze-thaw resistance, and can be used as substitutes for common cement concrete poles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com