A safety protection device for steel production

A safety protection device, steel technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problem of operator threat, no protective measures, etc., to prevent accidental injury, improve protection, and good quenching temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

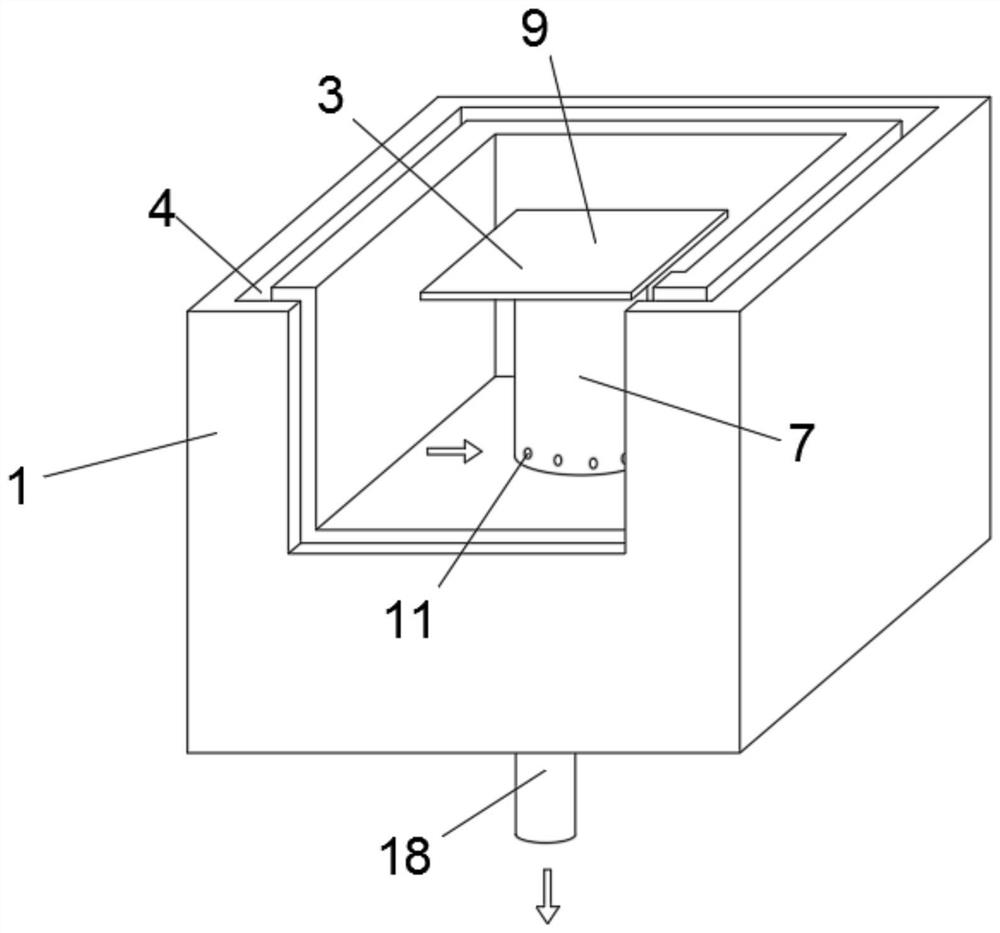

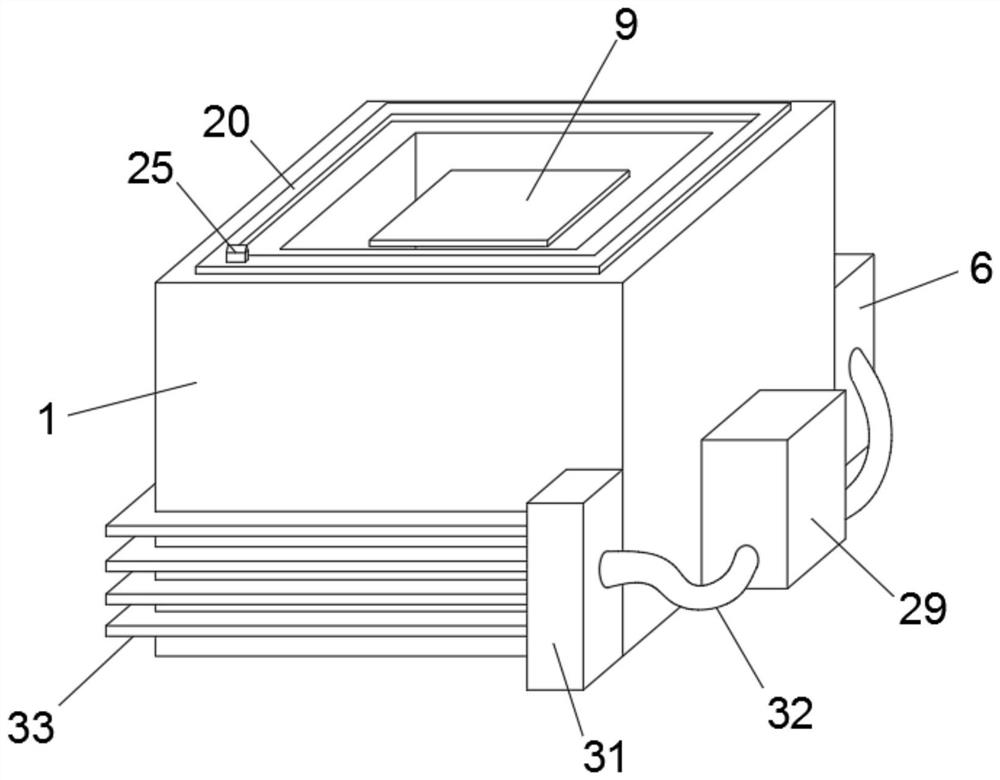

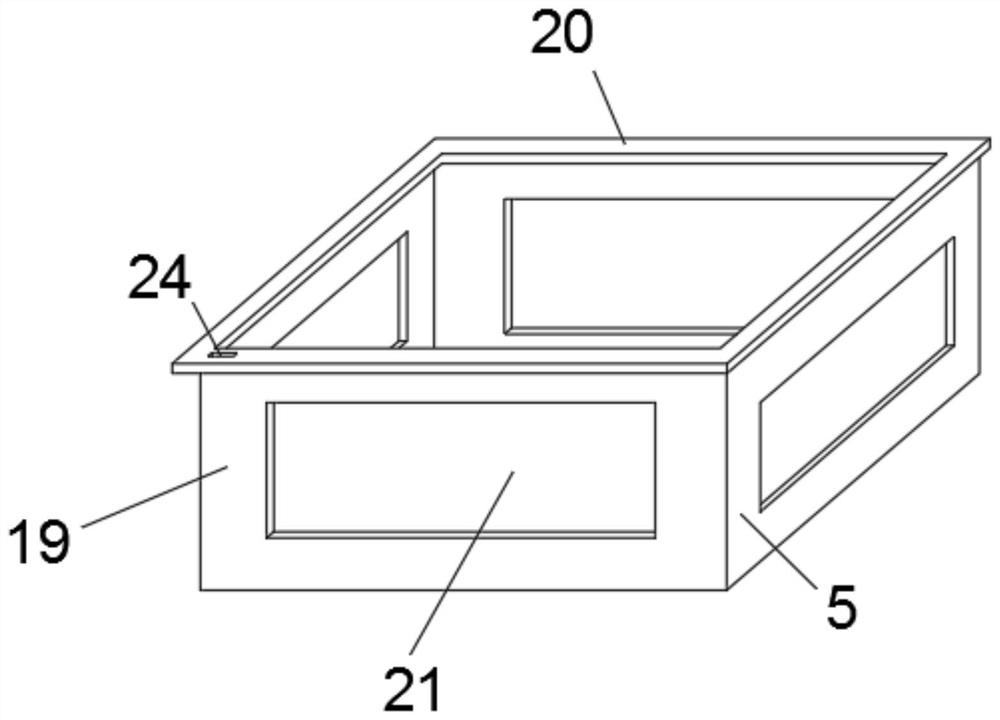

[0033] like Figure 1-9 As shown, a safety protection device for steel production includes a liquid holding pool 1, which is directly constructed on the ground of the production site. The liquid holding pool 1 is provided with a liquid holding chamber 2, which is located in the In the inner bottom of the liquid pool 1, the liquid holding chamber 2 is filled with extrusion fluid, the extrusion liquid is water liquid, the liquid holding chamber 2 is provided with an extrusion mechanism 3, and one end of the extrusion mechanism 3 runs through the liquid storage pool 1 at the center of the inner bottom of the , and extends into its interior.

[0034] The extrusion mechanism 3 includes an extrusion cylinder 7 arranged in the liquid chamber 2. The extrusion cylinder 7 is made of aluminum alloy and has good thermal conductivity. One end of the extrusion cylinder 7 is provided with an opening, and the other end is closed. The closed end Upwards, the closed end of the extrusion cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com