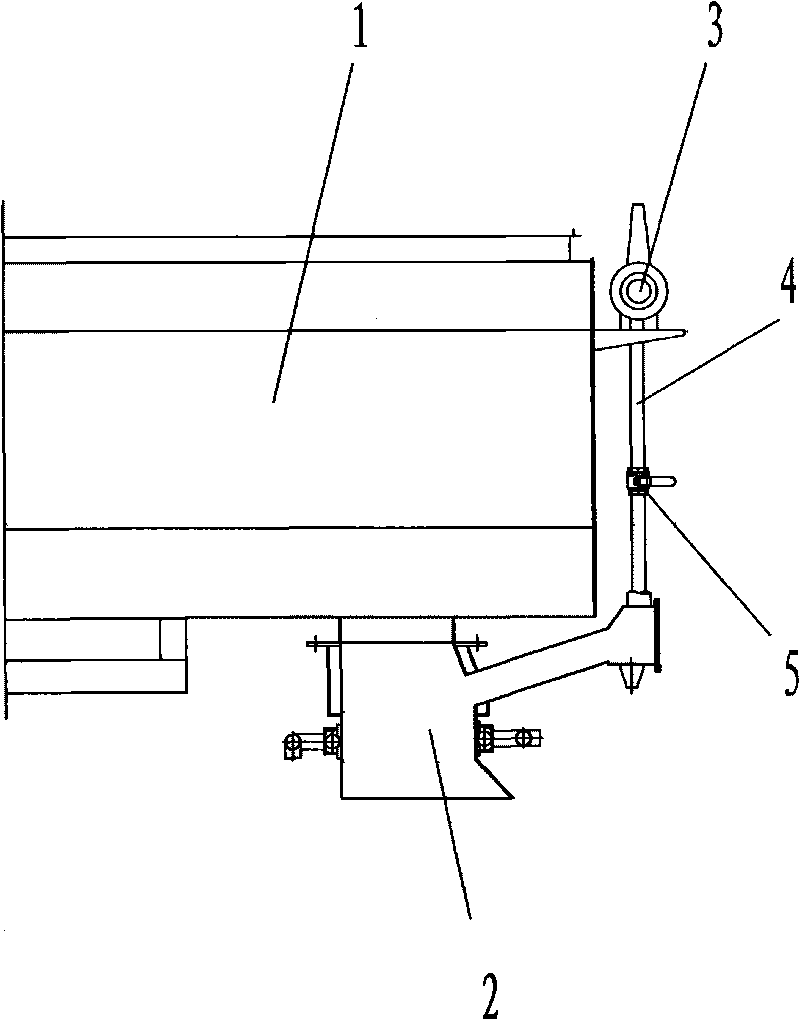

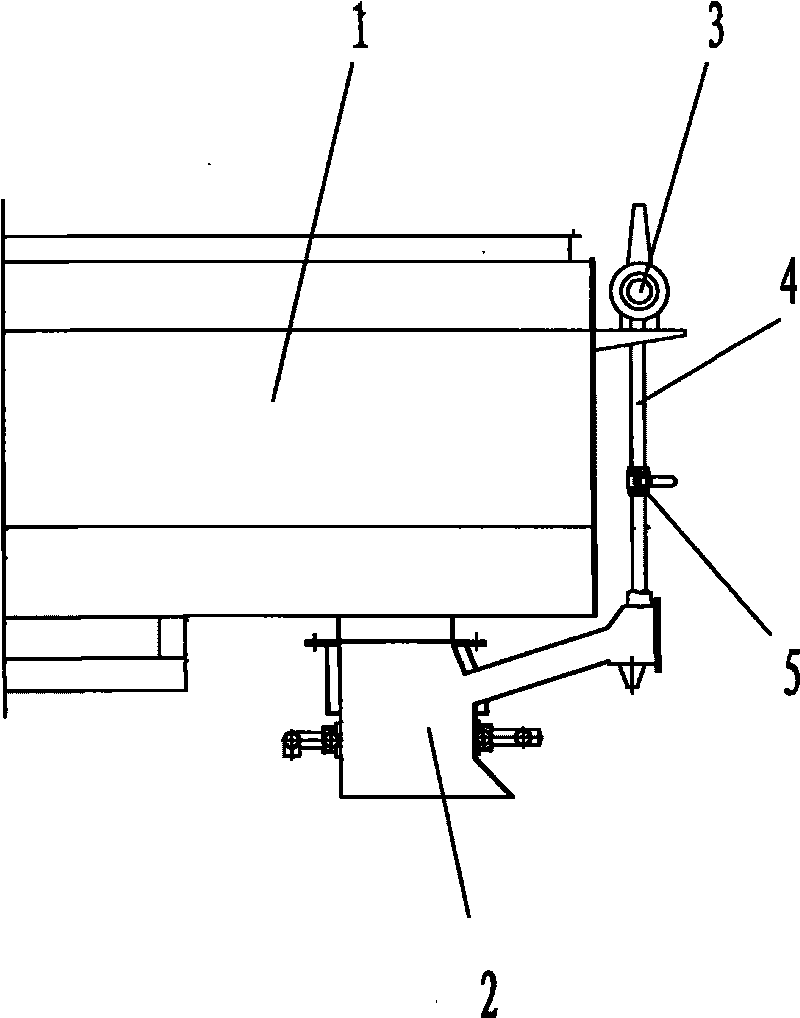

Hardening furnace with fume exhaust device

A quenching furnace and oil fume extraction technology, which is applied to quenching devices, furnaces, heat treatment furnaces, etc., can solve the problems of high maintenance costs of quenching furnaces and affect the normal production and operation of factories, so as to reduce maintenance costs, ensure quenching performance, and reduce carbon deposits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] See attached figure 1 , the quenching furnace with the range fume device of the present invention: comprising a quenching furnace hearth 1, a fume deposition box 2, a range fume pipe 4, a regulating valve 5, and a range hood 3; The lower part of the furnace is connected with the quenching furnace hearth 1, and the range hood 4 communicates with the oil fume deposition box 2, the regulating valve 5, and the range hood 3 in sequence. When working, turn on the range hood 3, and the oil fume in the oil fume deposition box 2 can be drawn out. Since the oil fume deposition box 2 is connected with the quenching furnace hearth 1 and is arranged at the bottom, the oil fume in the quenching furnace hearth 1 will also be discharged due to the pressure difference. It automatically enters into the oil fume deposition box 2, and then is drawn out of the furnace of the quenching furnace by the range hood. Reduce the carbon deposition in the hearth of the quenching furnace, so as to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com