Integrated method for forming tubular part

A technology for tubular parts and tube blanks, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of thinning the wall thickness of high-strength steel tubular parts, reducing the thickness of plates, and breaking the tubular parts, achieving high production efficiency and reducing energy. Optimum power consumption, performance and shape accuracy

Active Publication Date: 2020-07-28

初冠南

View PDF16 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] High-strength steel has a high weight-to-strength ratio and excellent weight-reducing effect. The advantages of high-strength steel make it rapidly developed and widely used in the automotive industry, so as to achieve the purpose of lightening the car and improving safety. At present, the application of high-strength steel It is limited to plate parts, which reduces the thickness of the plate. The corresponding technology is hot stamping, and another type of component on the car body is tubular parts. The preparation and processing methods of high-strength steel pipe-shaped parts that have been publicly reported mainly include the following two methods: 1. The first processing method is forming in a soft state, and then quenching to improve the strength of the high-strength steel pipe. This method is quenched outside the mold, which is easy to ensure the heat treatment effect, but the disadvantage is that quenching deformation cannot be avoided; another method is hot gas The shortcomings of this method are: a series of problems such as excessive air pressure required, serious wall thickness reduction of high-strength steel pipe-shaped parts, uneven quenching, rupture of pipe-shaped parts, and wrinkling forming defects have not been solved so far. widely used

At present, there is no technology that can solve the problem of efficient production of high-strength steel pipe-like parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 3

[0039] Embodiment 3: The initial tube blank in step 1 is one of high-strength steel and high-temperature alloy.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

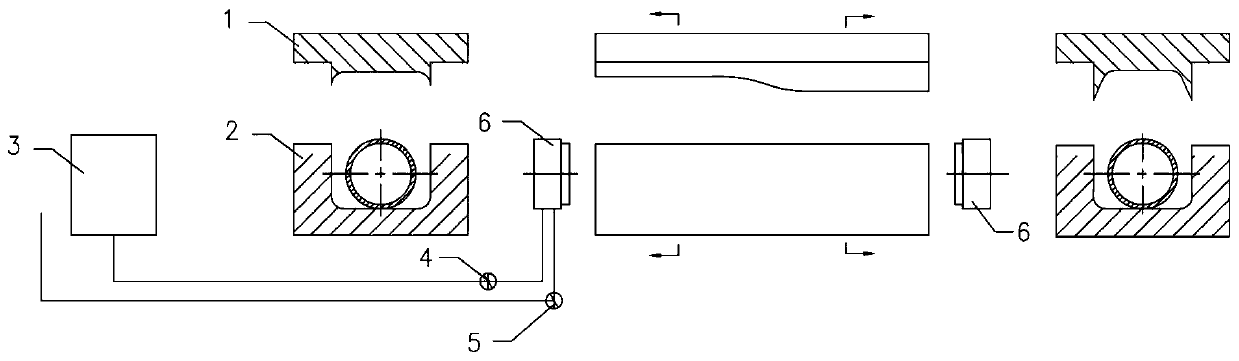

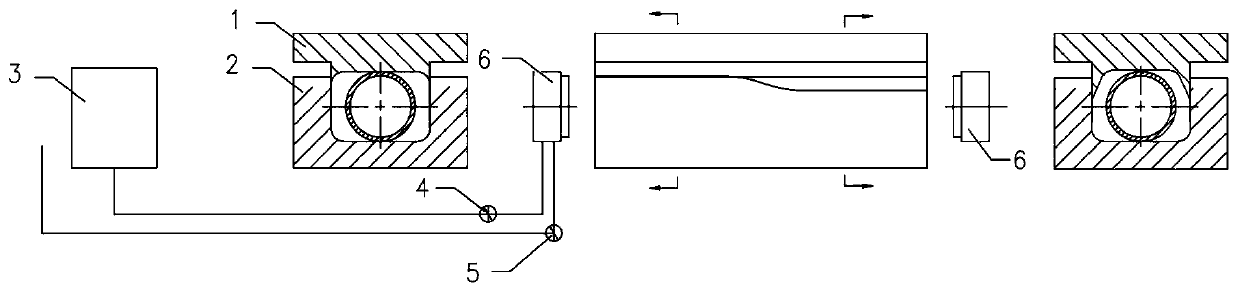

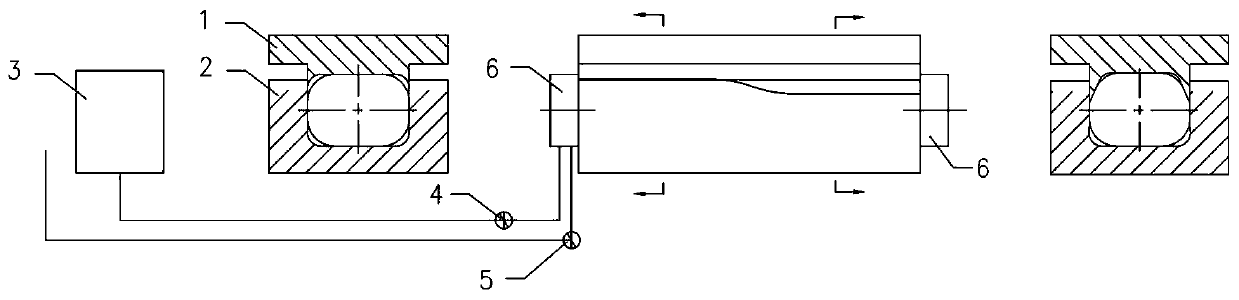

The invention provides an integrated method for forming a tubular part. The method comprises the following steps that 1, an initial tube blank is selected; 2, a mold closing position A and a positionB are determined; 3, the initial tube blank is heated to the temperature T, and T is in the scope of 300 DEG C-1400 DEG C; 4, a die is opened, the initial tube blank is put in a lower die, and an upper die is closed to the position B; 5, the two ends of the initial tube blank are sealed, a first valve is opened, fluid medium with pressure P fills the interior of the initial pipe blank, the initialtube blank is expanded to partially attached to the die, and the sharp portion of the initial tube blank is not completely attached to the die; 6, the internal pressure of the initial tube blank is adjusted to pcr; 7, the upper die moves to the die closing position A to be completely attached to the die; 8, a second valve is opened, the die is quenched under an internal pressure support; 9, the first valve is closed, the sealing of the tube blank is removed, and the second valve is closed; and 10, the die is opened to take out a workpiece. According to the integrated method, the high-strengthsteel material forming and quenching integration is achieved, the shape precision and the heat treatment effect meeting the requirements are produced, and the manufacturing bottleneck is broken through.

Description

technical field [0001] The invention relates to a forming method in the technical field of industrial manufacturing, in particular to a form-integrated method for forming a tubular member. Background technique [0002] High-strength steel has a high weight-to-strength ratio and excellent weight-reducing effect. The advantages of high-strength steel make it rapidly developed and widely used in the automotive industry, so as to achieve the purpose of lightening the car and improving safety. At present, the application of high-strength steel It is limited to plate parts, which reduces the thickness of the plate. The corresponding technology is hot stamping, and another type of component on the car body is tubular parts. The preparation and processing methods of high-strength steel pipe-shaped parts that have been publicly reported mainly include the following two methods: 1. The first processing method is forming in a soft state, and then quenching to improve the strength of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D26/033C21D9/08C21D8/10C21D1/673

CPCB21D26/033C21D9/08C21D8/105C21D1/673Y02P10/25

Inventor 初冠南孙磊

Owner 初冠南

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com