Waste gas high-efficiency cooling system with high EGR efficiency

A cooling system, EGR valve technology, applied in the charging system, exhaust gas recirculation, adding non-fuel substances to the fuel, etc., can solve the thermal deformation and thermal stress of the cooler, affect the service life of the cooler, and cannot be convenient for cars, etc. problems, to achieve the effect of improving efficiency, improving durability and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

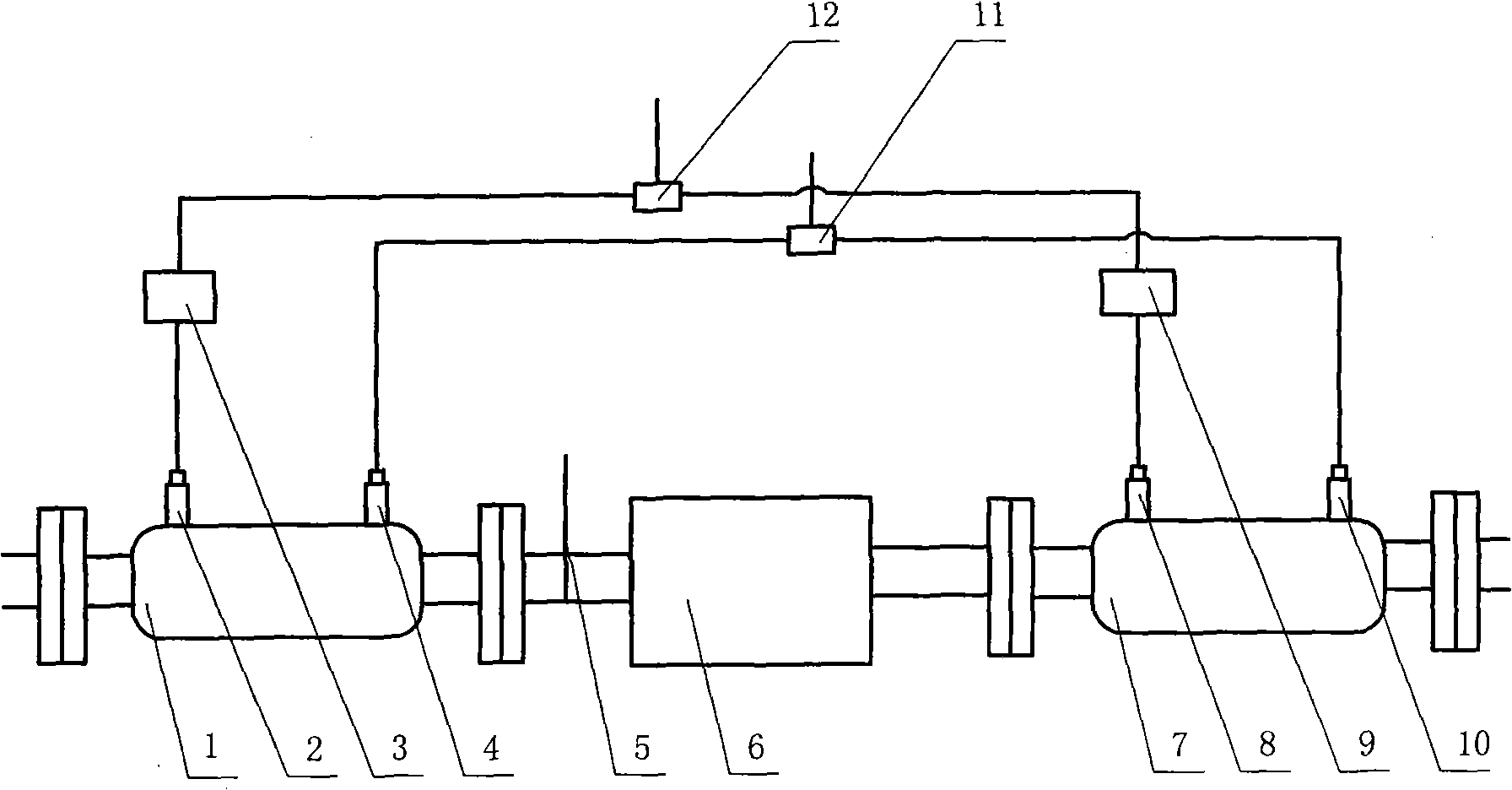

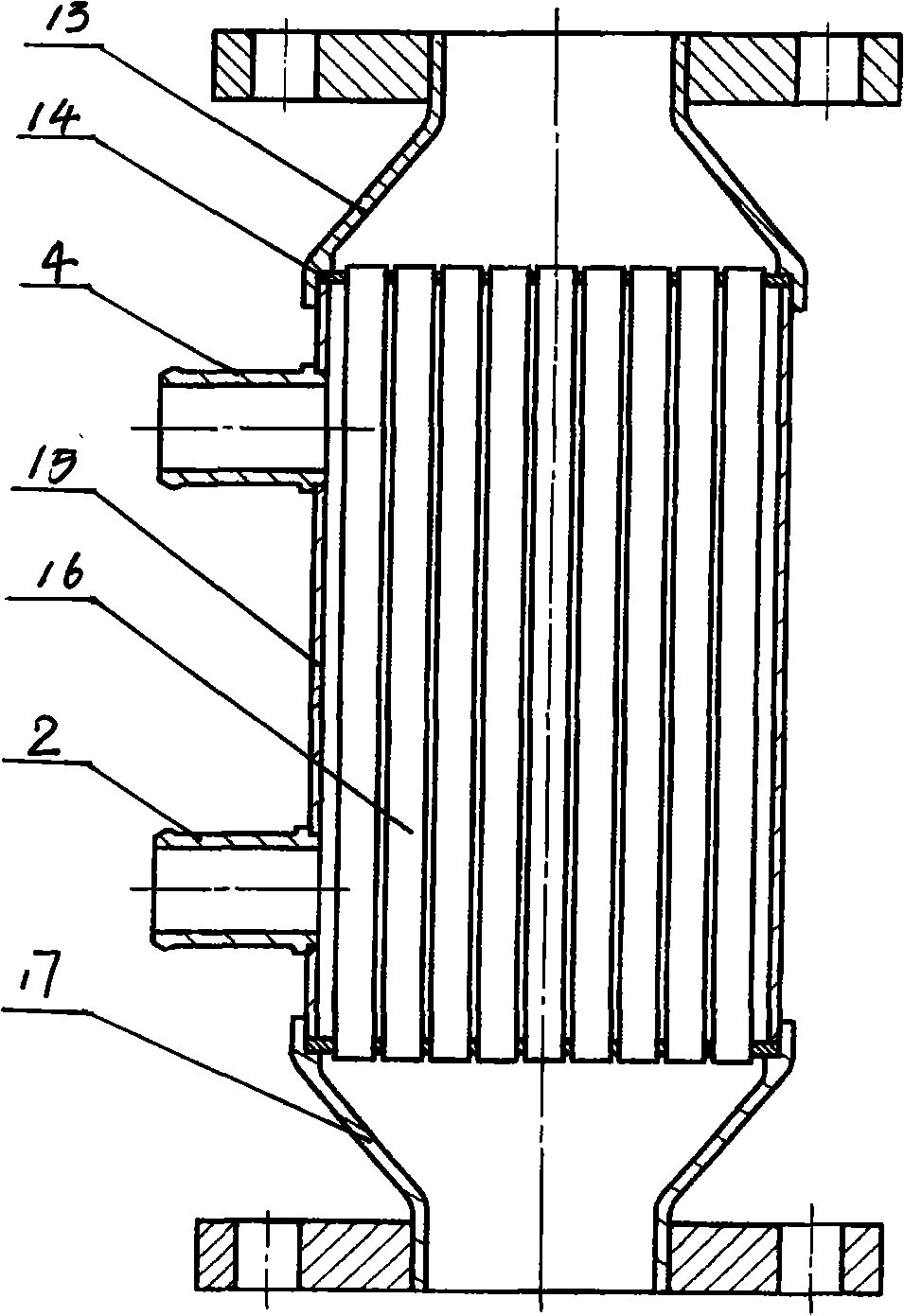

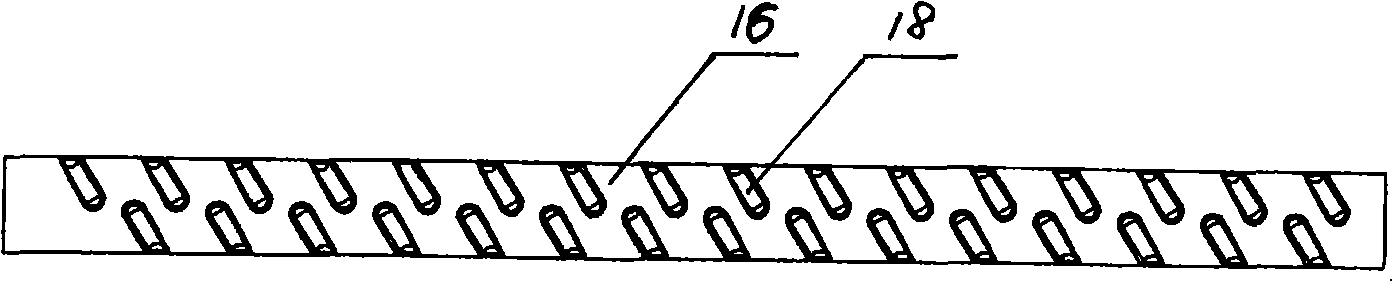

[0019] A high-efficiency exhaust gas cooling system with high EGR rate includes a cooler connected with an EGR pipe and an EGR valve. The innovation of the cooling system is that it includes a pre-cooler 1 and a post-cooler 7, and the EGR valve 6 is installed in series between the pre-cooler and the post-cooler. The pre-cooler cools the high-temperature and high-flow exhaust gas introduced from the exhaust end, and the rear cooler cools the cooled exhaust gas coming out of the pre-cooler. The ultimate goal of these two coolers is to control the exhaust gas within a reasonable temperature ( 150-200°C). The EGR valve controls the amount of exhaust gas introduced into the cooling system, and precisely adjusts the exhaust gas according to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com