Manufacturing method for cross-shaped column rotation circular pipe column structure and cross-shaped column rotation circular pipe column structure thereof

A manufacturing method and technology of cross columns, which are applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor dimensional accuracy, high difficulty in component processing, and poor integration of cross parts and round pipe parts, etc., to reduce welding Deformation and residual stress, ensuring appearance and dimensional quality, and good overall structural stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0046] Referring to the accompanying drawings, it can be known that the manufacturing method of the cross-column-to-cylindrical column structure is characterized in that it comprises the following steps:

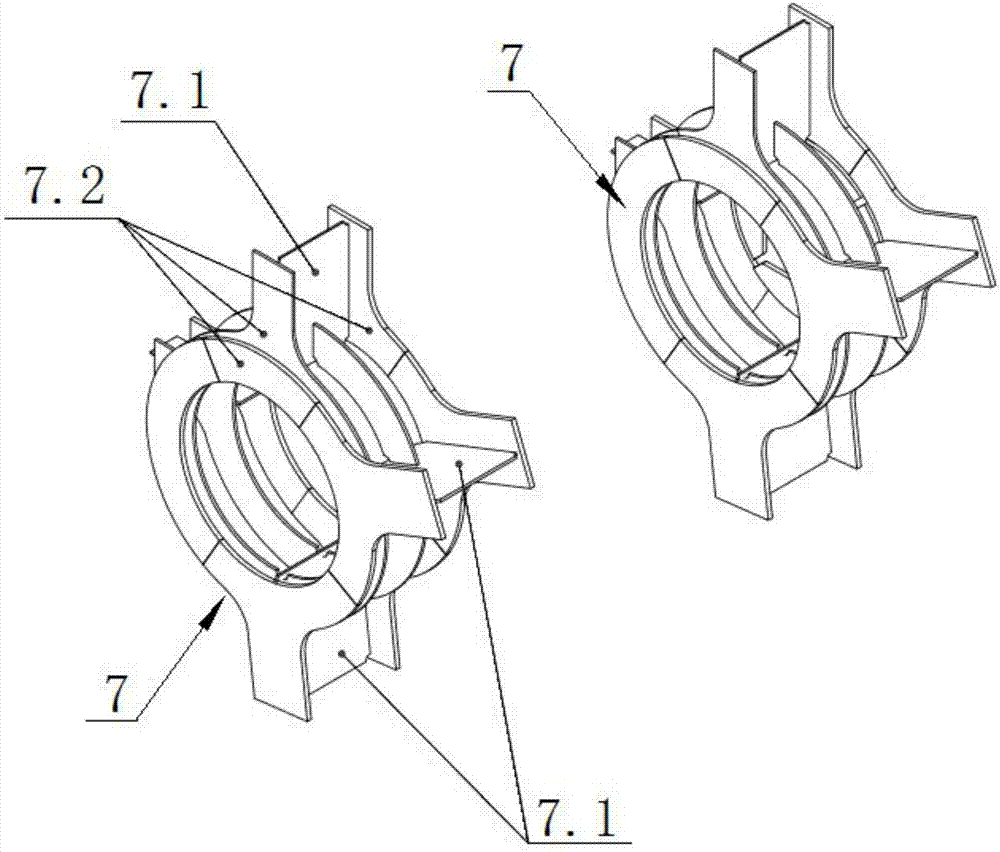

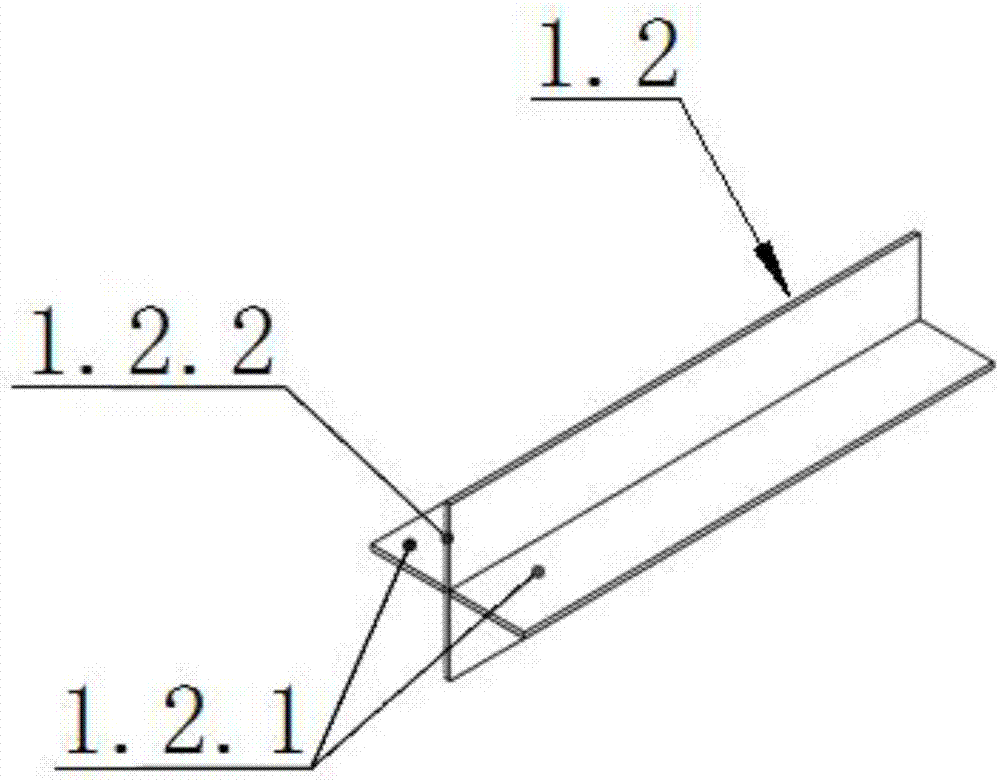

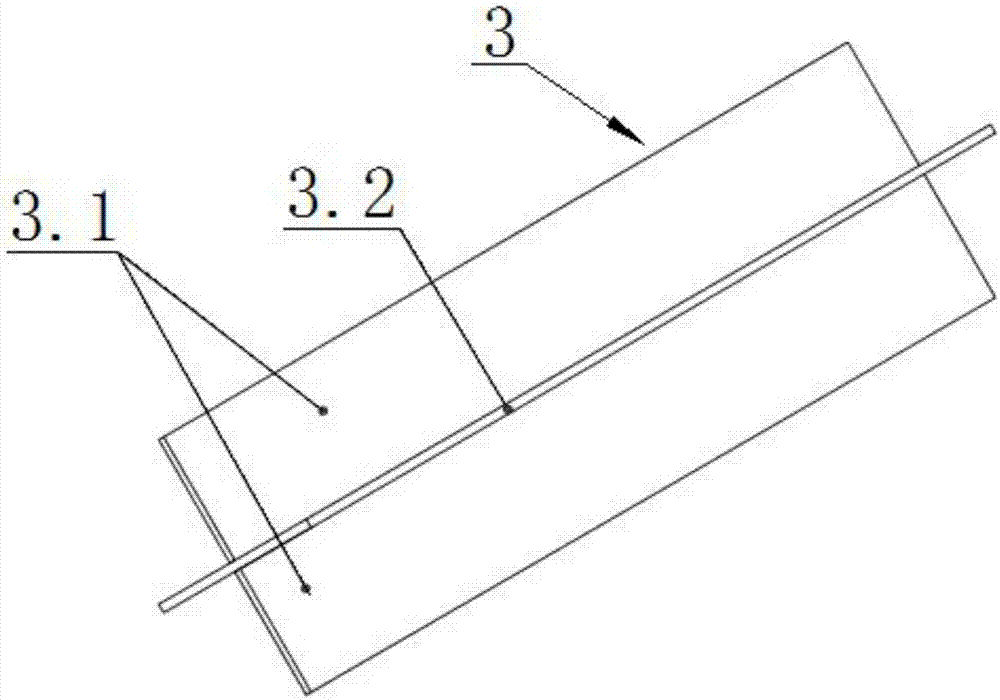

[0047] Step 1: Assembling the annular H-shaped corbel: Assemble four annular flange plates 7.1 and four annular H-shaped corbel webs 7.2 to form the first annular H-shaped corbel 7; refer to the first annular H-shaped corbel The assembly method of 7 assembles the second annular H-shaped corbel 7; reserve carbon dioxide gas protection for the strip formed between the annular flange plate 7.1 of the two annular H-shaped corbels 7 and the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com