Method for sheathing and rolling as-cast TiAl alloy platebased on composite structural design

A technology of alloy sheet and composite structure, which is applied in the field of intermetallic compound material sheet manufacturing, can solve the problems of difficult preparation of thin sheets, achieve low-cost thin sheets, reduce sheet costs, and achieve high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of the blank in step 1: the TiAl alloy ingot is obtained through vacuum consumable arc melting and three times of remelting, followed by homogenization annealing treatment. The plate-shaped blank is obtained by wire electric discharge cutting, and after mechanical grinding treatment, the surface finish reaches Ra6-Ra8, and then chamfering treatment is used as the base material for rolling.

[0029] Step 2 Composite sheathed slab preparation:

[0030] The surface of the TiAl slab is uniformly covered with heat-resistant glass coating / graphite paper as an anti-oxidation / lubricating coating.

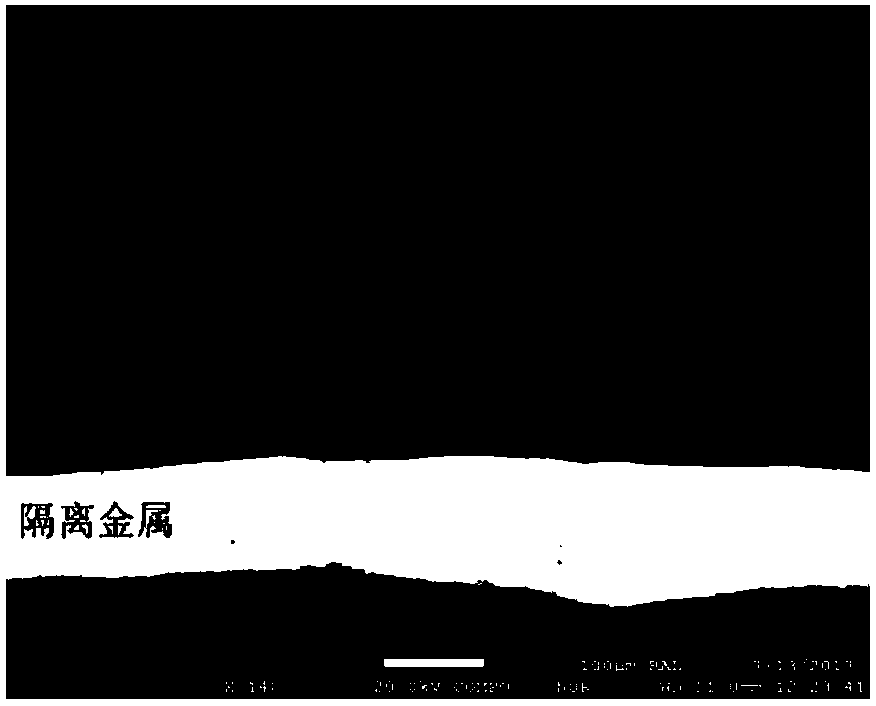

[0031] Select a chemically stable and heat-insulating metal material (pure titanium or titanium alloy) as the inner layer jacket, with a thickness of 1-10mm; the inner layer jacket can prevent heat flow loss, interface reaction and surface oxidation, and the thickness is too thin It is easy to lead to poor protection performance and unstable sheath structure during r...

Embodiment 1

[0039] In this embodiment, the method for directly rolling the as-cast TiAl alloy plate based on the composite sheath structure design, the specific method is as follows:

[0040]Billet preparation: TiAl alloy ingots were obtained by vacuum consumable arc melting, and 10mm thick square billets were obtained by wire electric discharge cutting. After mechanical grinding, the surface finish was Ra7, and TiAl alloy rolling billets were obtained;

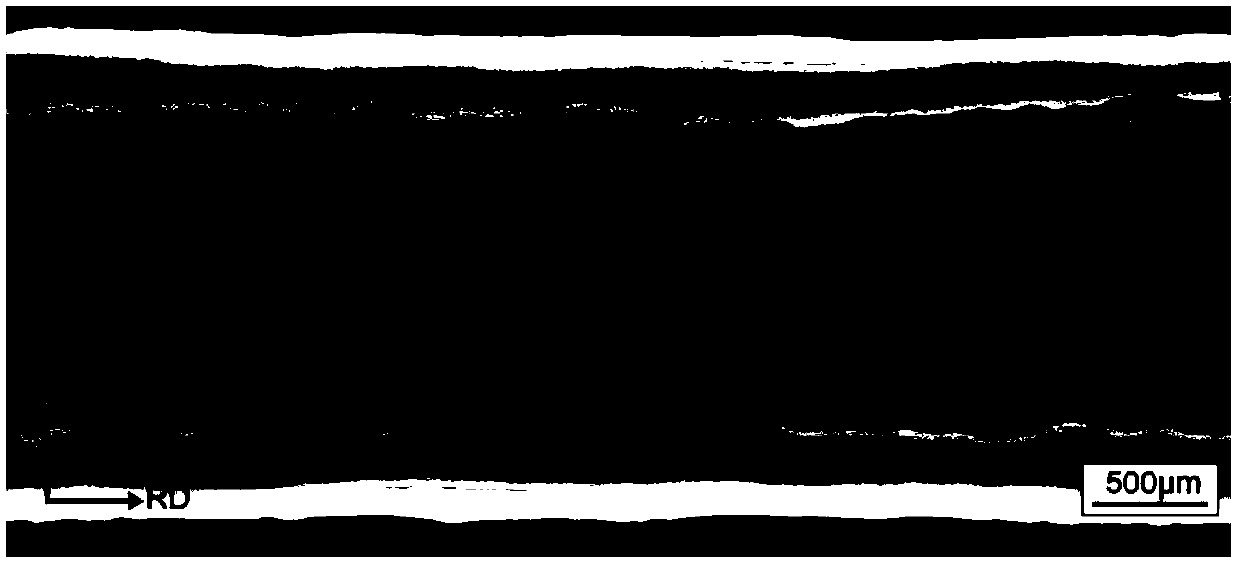

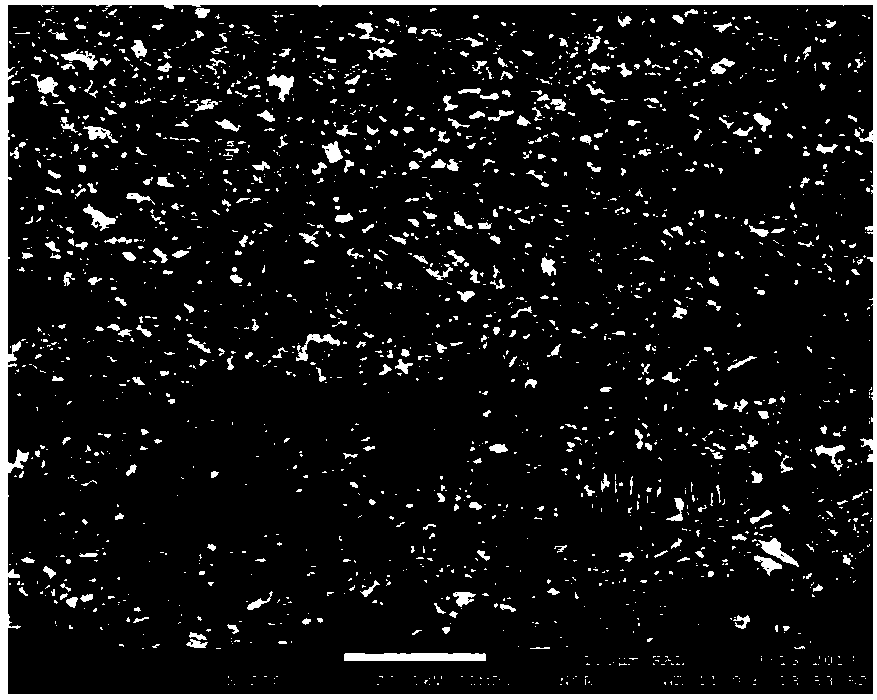

[0041] The production of the sheath: First, the surface of the TiAl alloy is evenly covered with a heat-resistant glass anti-oxidation coating with a thickness of 0.2mm; then the TC4 titanium alloy is used as the inner sheath material for sealing and welding by a vacuum electron beam welding machine to obtain the inner layer Sheath; place isolated metal plates (such as: Mo sheet, thickness 0.3mm) on both sides of the inner sheath and then make the outer sheath; the material of the outer sheath is 2520 stainless steel and seal welding, the...

Embodiment 2

[0047] The difference from Example 1 is that in this example, the selected inner and outer sheath materials are pure titanium and nickel-based superalloy respectively, the rolling and holding temperature is 1250°C, and the rolling speed is 0.1m / s , The pass deformation is 10% to 15%. Other processing steps and process parameters are the same as in Embodiment 1. The final total deformation is 90%, the thickness of the obtained TiAl alloy sheet is 1-1.1mm, the surface smoothness is good, and there is no crack defect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com