Variable Radius Bending Method for Longitudinal Welded Pipe Roll Forming

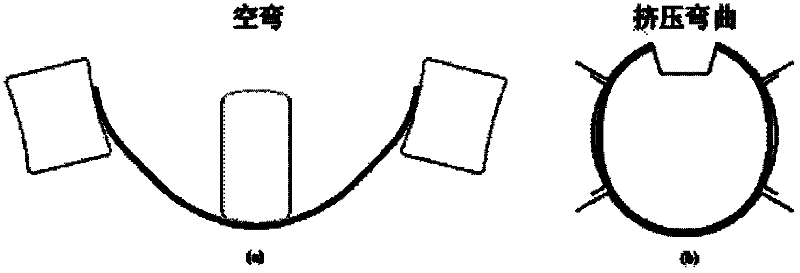

A technology of straight seam welded pipe and roll forming, which is applied in the field of roll forming and variable radius bending of straight seam welded pipe based on deformation blind area, which can solve the problems of strip deformation blind area and incomplete contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

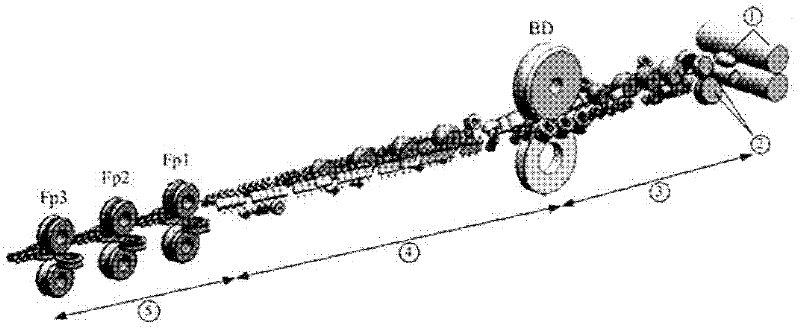

[0044] 1. Adopt the variable radius bending method of straight seam welded pipe roll forming of the present invention, carry out the forming of strip steel for the φ325mm welded pipe roll forming process under four kinds of different downhill amounts (0.1D, 0.4D, 0.7D, 1.0D) respectively volume design. The other initial input parameters for forming volume design are:

[0045] The final formed tube radius R=325 / 2mm;

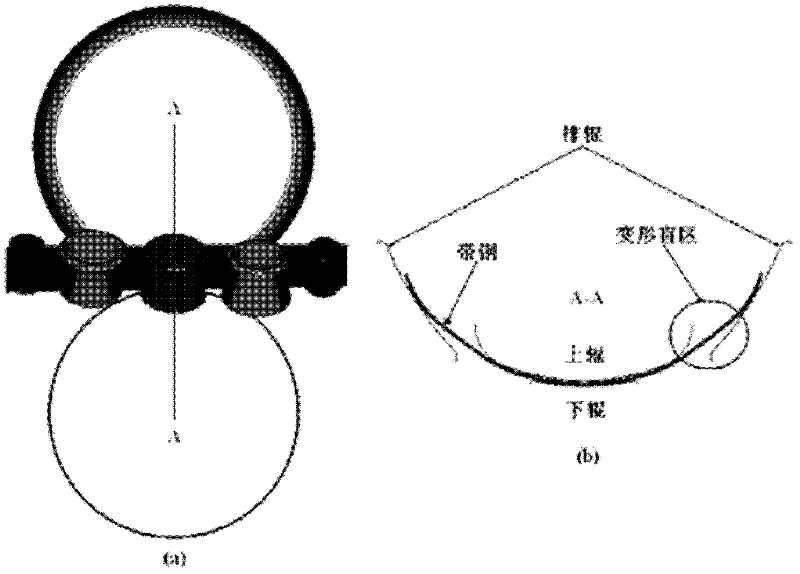

[0046] The starting point of deformation blind zone a=0.5;

[0047] The end point of the deformation dead zone b=0.72;

[0048] Edge bending angle θ 3 = 38;

[0049] The radius of curvature R of the deformation dead zone 2 =R / 0.1=1625mm;

[0050] Fine forming first pass F p1 The vertical position coordinate value of Z fp1 =16100mm;

[0051] Fine forming first pass F p1 The width of the guide ring W f1 =64.38mm.

[0052] like Figure 5-Figure 7 As shown, this embodiment includes the following steps:

[0053] The first step is the longitudinal deformat...

Embodiment 2

[0079] Adopt the variable-radius bending method of roll forming of straight seam welded pipe of the present invention, carry out the forming amount design of strip steel for four kinds of different descending amounts (0.1D, 0.4D, 0.7D, 1.0D) under the roll forming process of φ406mm welded pipe . The other initial input parameters for forming volume design are:

[0080] The final formed tube radius R=406 / 2mm;

[0081] The starting point of deformation blind zone a=0.53;

[0082] The end point of the deformation dead zone b=0.75;

[0083] Edge bending angle θ 3 = 38;

[0084] The radius of curvature R of the deformation dead zone 2 =R / 0.1=2030mm;

[0085] Fine forming first pass F p1 The vertical position coordinate value of Z fp1 =16100mm.

[0086] According to the above-mentioned variable radius bending method, the parameters of the forming quantity with a descending amount of 0.7D are finally obtained as listed in Table 2, and the designed forming shape bitmaps under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com