A kind of low-density impact-resistant metal material and its manufacturing method

A technology of metal materials and production methods, which is applied in the field of low-density impact-resistant metal materials and the production of low-density impact-resistant metal materials, can solve the problems of lack of mechanical properties, high density, and low plasticity, so as to improve anti-wear ability and anti-corrosion Impact ability, low density and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A low-density impact-resistant metal material, the innovation of which is: the following mass percentages are included: 1.5-3.1% C, 1.2-1.9% Si, 1.69-2.32% Mn, 0.033-0.042% S, 0.021-0.025% P , 1.8-3.6% Cr, 1.6-3.6% Ni, 1.56-2.25% Mo, 0.45-0.68% Co, 0.63-1.18% Fe, and the rest is Cu.

[0029] A method for manufacturing a low-density impact-resistant metal material, including the treatment steps of melting period and reduction period, and its innovative point is that the specific steps are as follows:

[0030] (1) Select material: select the material with the following mass percentages: 1.8-2.6%C, 1.4-1.7%Si, 1.77-2.01%Mn, 0.036-0.040%S, 0.023-0.025%P, 2.3-3.2%Cr, 2.1 -3.1% Ni, 1.66-1.98% Mo, 0.54-0.61% Co, 0.77-0.98% Fe, the rest is Cu;

[0031] (2) Pouring: pour the material in step (1) at a temperature of 1250-1520°C, and control the pouring time to 2-3 hours;

[0032] (3) Cooling in the metal mold billet: demoulding at 780-930°C, and putting it into the heat preserv...

Embodiment 2

[0036] On the basis of Example 1, change the ratio of metal material raw materials, specifically 1.8-2.6% C, 1.4-1.7% Si, 1.77-2.01% Mn, 0.036-0.040% S, 0.023-0.025% P, 2.3 -3.2% Cr, 2.1-3.1% Ni, 1.66-1.98% Mo, 0.54-0.61% Co, 0.77-0.98% Fe, and the rest is Cu.

[0037] According to the production method and parameter selection of Example 1, the pouring temperature is set at 1250-1320°C; the demoulding temperature is 880°C; and the tempering temperature is 535°C.

Embodiment 3

[0039] On the basis of Example 1 or 2, change the ratio of metal material raw materials, specifically 2.2% C, 1.5% Si, 1.89% Mn, 0.038% S, 0.024% P, 2.6% Cr, 2.7% Ni, 1.78 %Mo, 0.58% Co, 0.87% Fe, and the rest is Cu.

[0040] According to the production method and parameter selection of Example 1, the casting temperature is set to 1280°C; the demoulding temperature is 880°C; and the tempering temperature is 535°C.

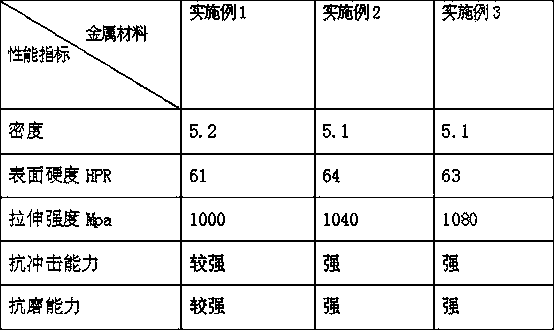

[0041] The product performance parameter of above embodiment is as shown in table 1 below:

[0042]

[0043]It can be seen from the above table 1 that, compared with the metal materials in the prior art, the density of the metal material of the present method is greatly reduced, and the impact resistance and wear resistance are greatly enhanced, and the present invention has great substantial progress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com