Machining apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

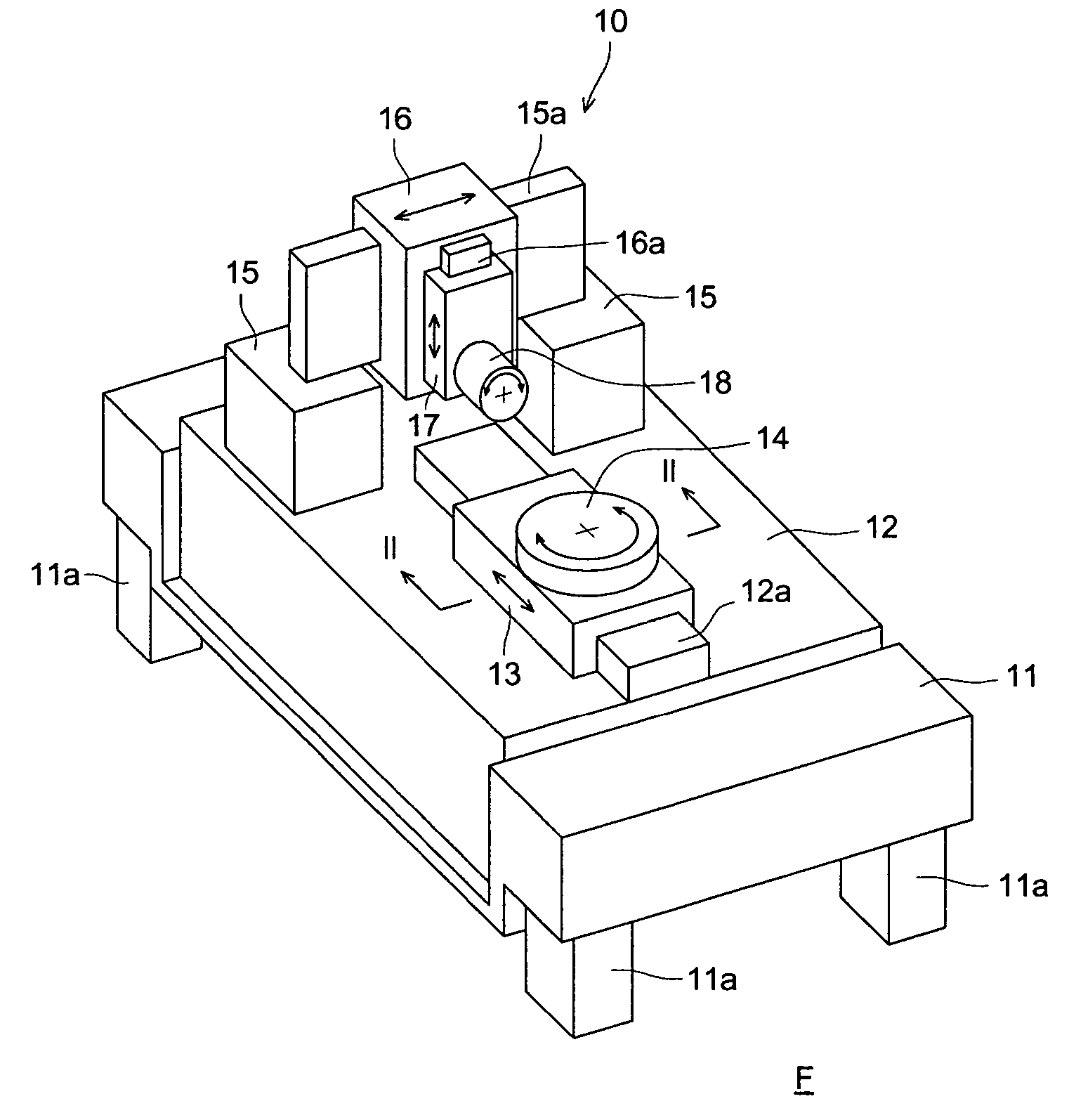

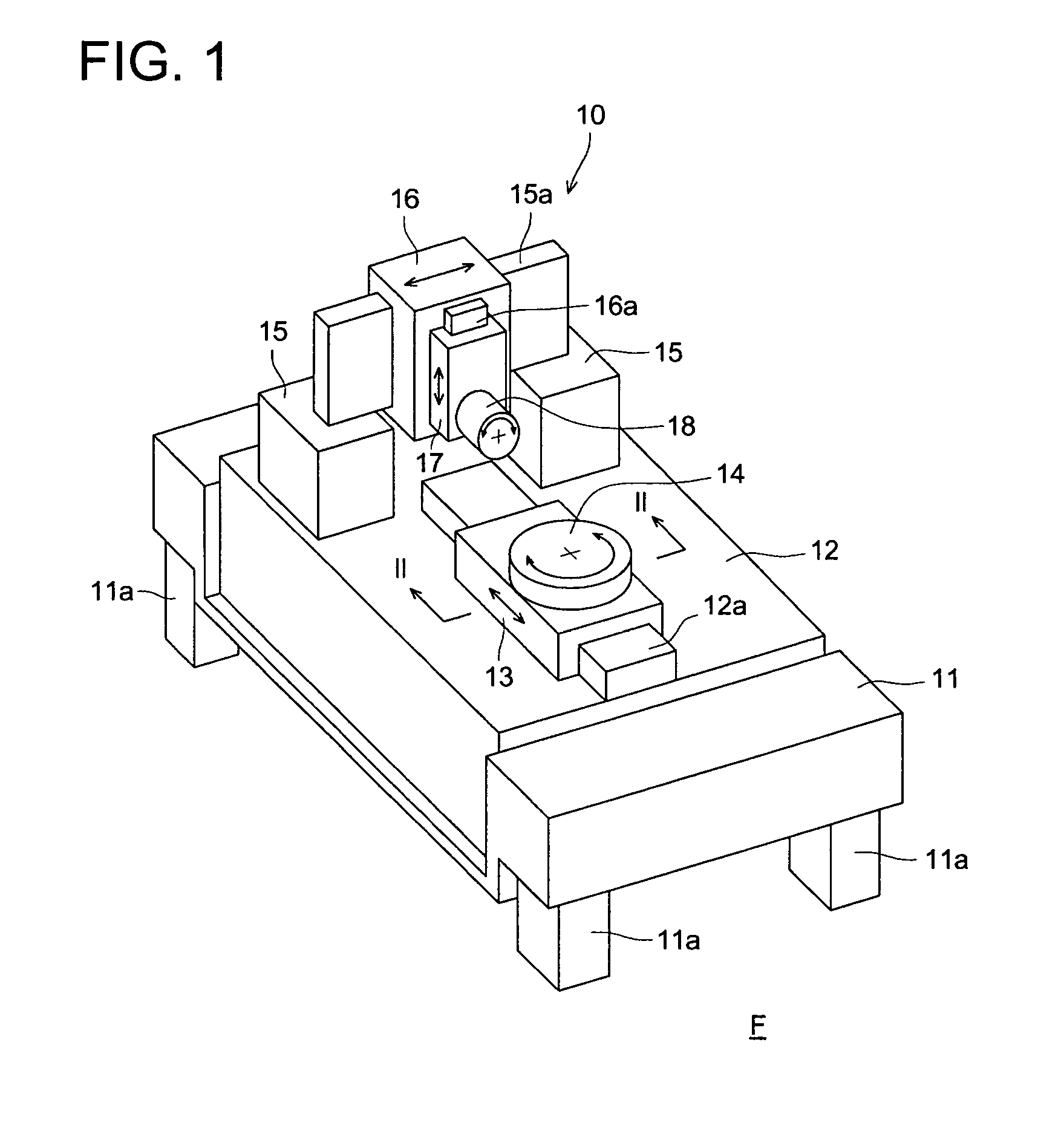

Image

Examples

Embodiment Construction

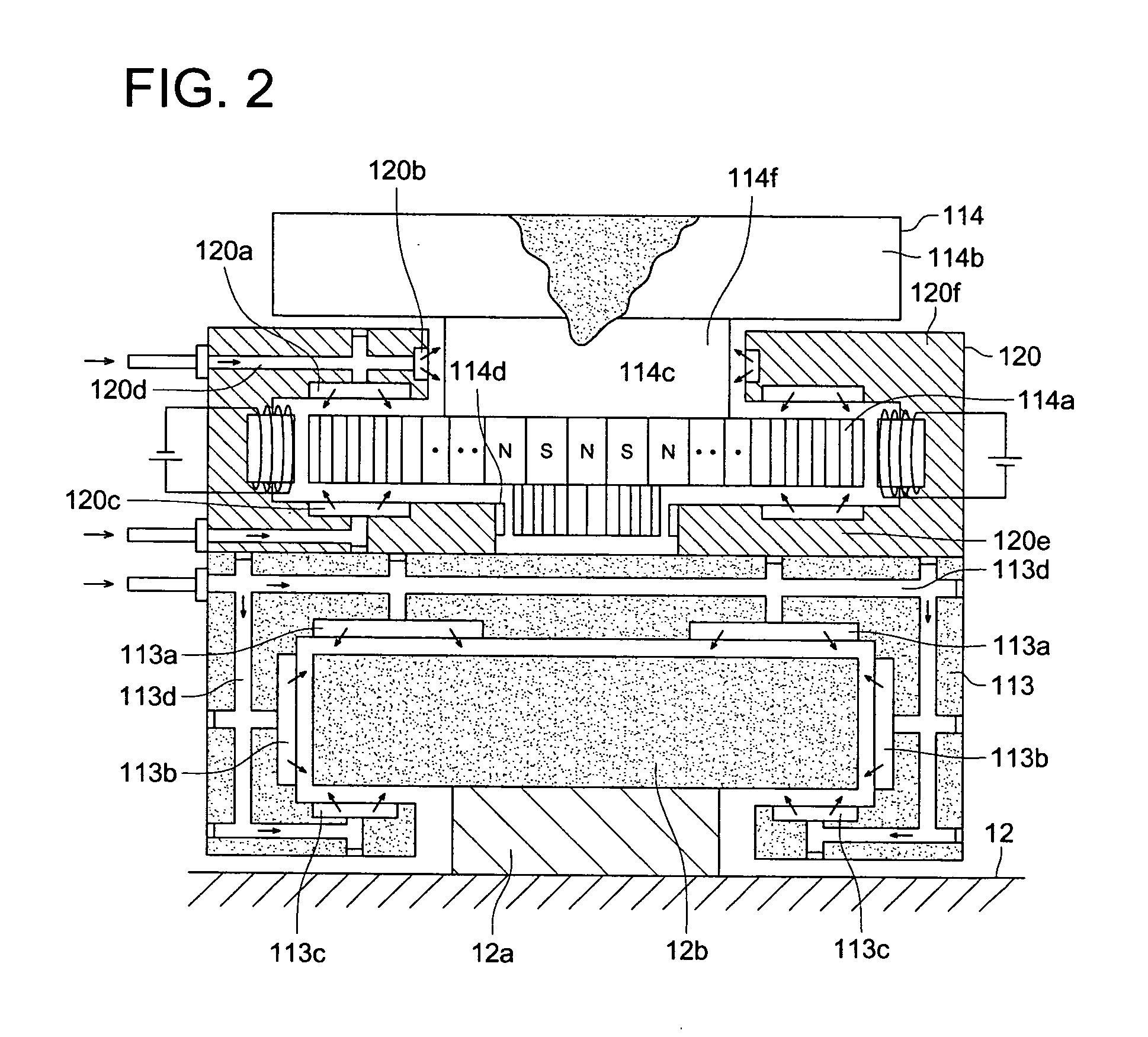

[0024] Firstly, the preferable structures according to the present invention are explained.

[0025] A machining apparatus set forth in Item (2) is a machining apparatus as set forth in the Item (1), wherein the aforesaid ceramic material has a coefficient of linear expansion of 5×10−6 K−1 or less; therefore, as compared to cast iron, its thermal expansion can be suppressed to be low by half or less; therefore, the accuracy of machining can be maintained secured while the acceleration ability is made higher owing to its weight being made lighter, which makes it possible to shorten the machining time.

[0026] A machining apparatus set forth in Item (3) is a machining apparatus as set forth in the Item (1) or (2), wherein the aforesaid ceramic material contains silicon nitride of 50% or more by weight as converted into Si3N4 and has a specific weight of 4 g / cm3; therefore, the weight of the aforesaid workbench becomes a half or less of a conventional one, and even if the power of the axi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com