Guide rail profile integrated module and manufacturing process thereof

An integrated, guide rail technology, applied in the field of guide rail modules, can solve problems such as unfavorable market competitiveness, reduce work efficiency, increase process steps, etc., and achieve the effects of saving machining time, convenient processing, and easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

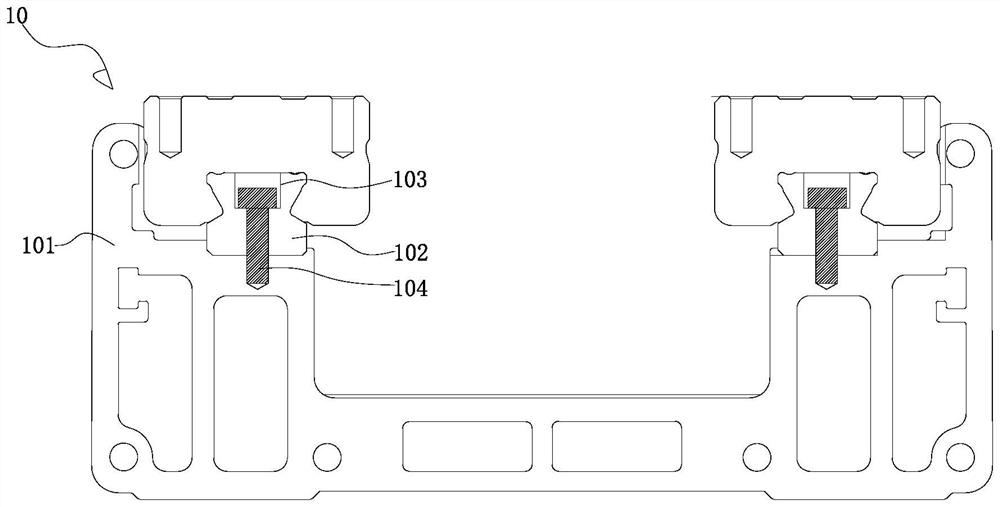

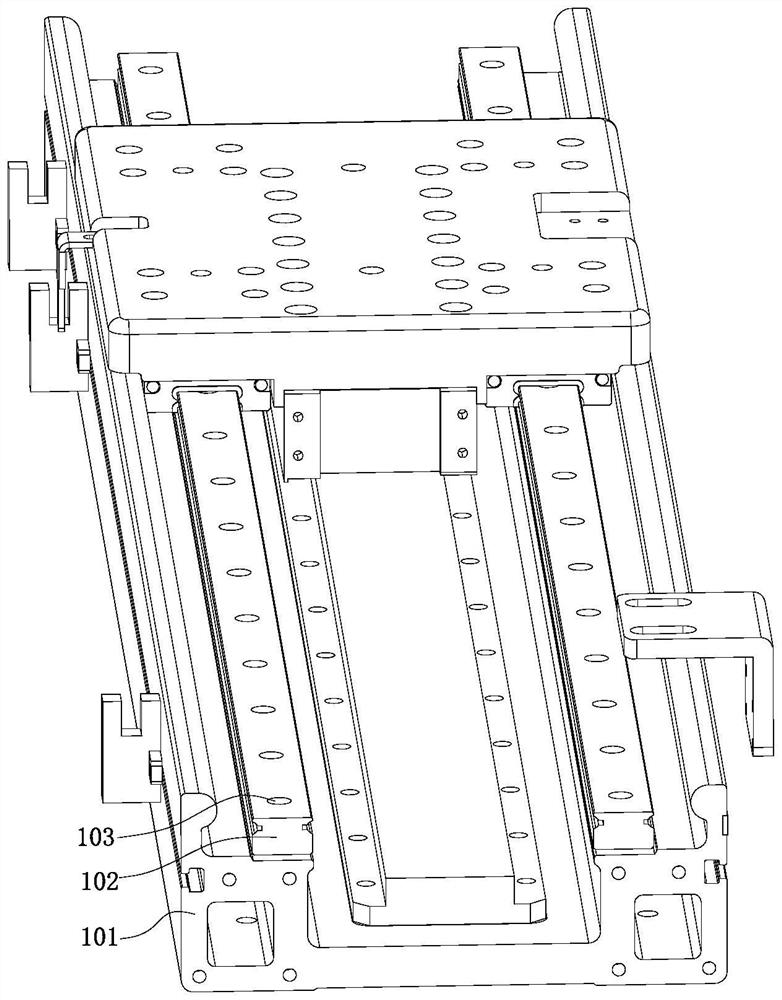

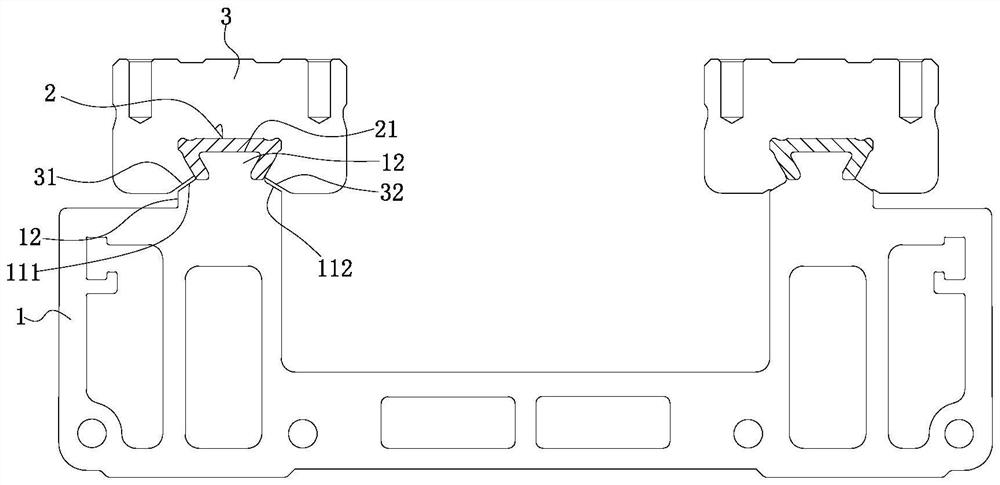

[0026] See Figure 3-Figure 4 As shown, it is an integrated module of rail profiles, which includes a carbon fiber profile 1 made of carbon fiber composite material and two rails 2 arranged on both sides of the upper end face of the carbon fiber profile 1, and the rails 2 protrude from the carbon fiber. The upper end surface of the profile 1 is outside, wherein the carbon fiber profile 1 and the guide rail 2 are fixed as a whole by means of in-mold forming. The present invention uses carbon fiber composite materials to form carbon fiber profiles 1, and replaces aluminum alloy profiles, which has lower cost, more convenient processing and manufacturing, and can also reduce the overall weight of the module, which is convenient for installation and use; in addition, the guide rail 2 and the carbon fiber profile 1 Through in-mold forming, the fixing met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com